Moso bamboo slivering machine

A technology for making a strip machine and bamboo, which is applied in the field of mechanical devices and can solve problems such as low efficiency and complex strip material processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

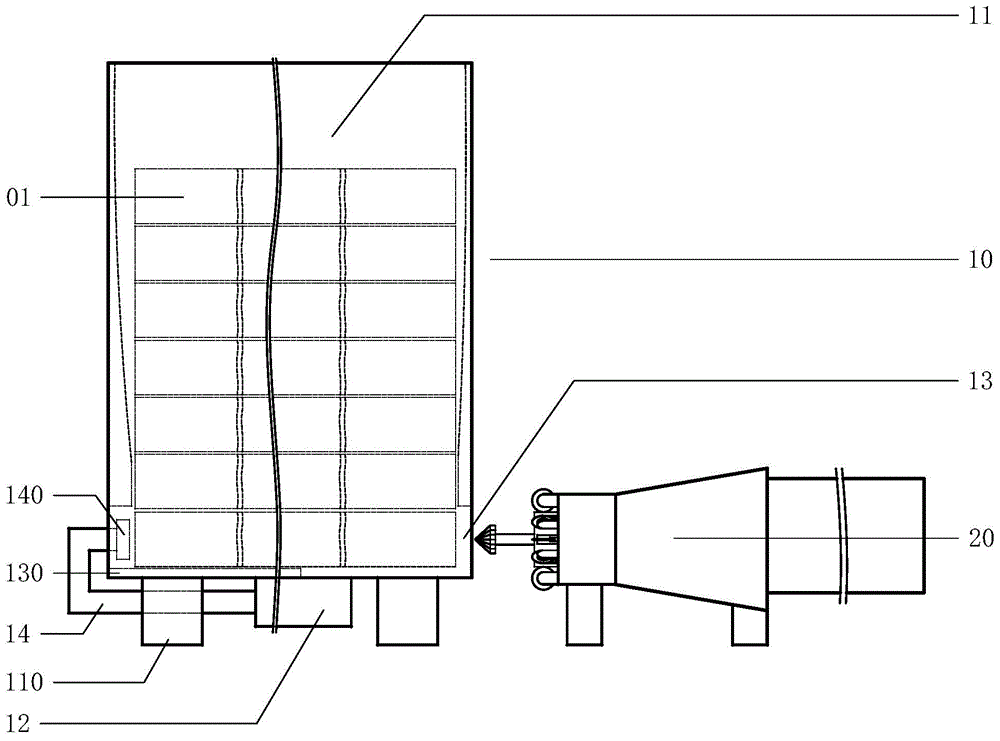

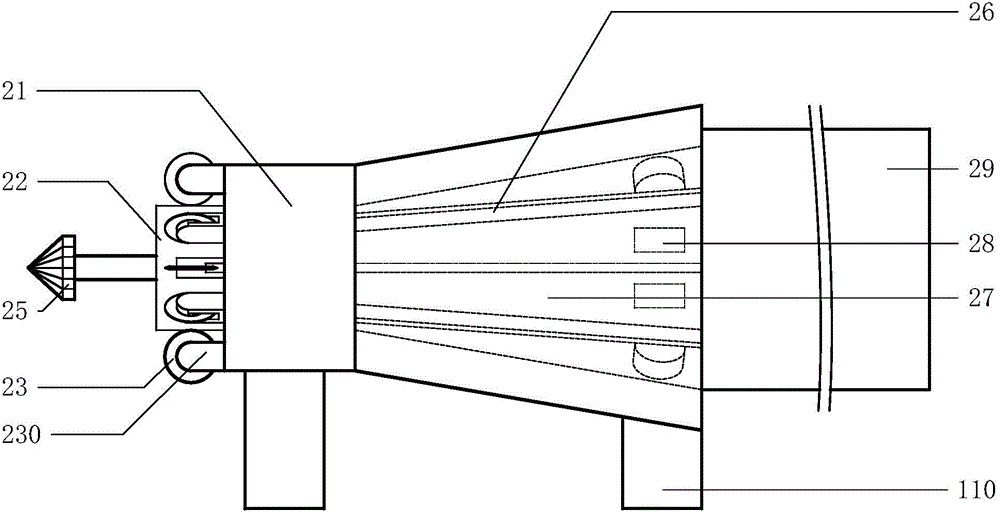

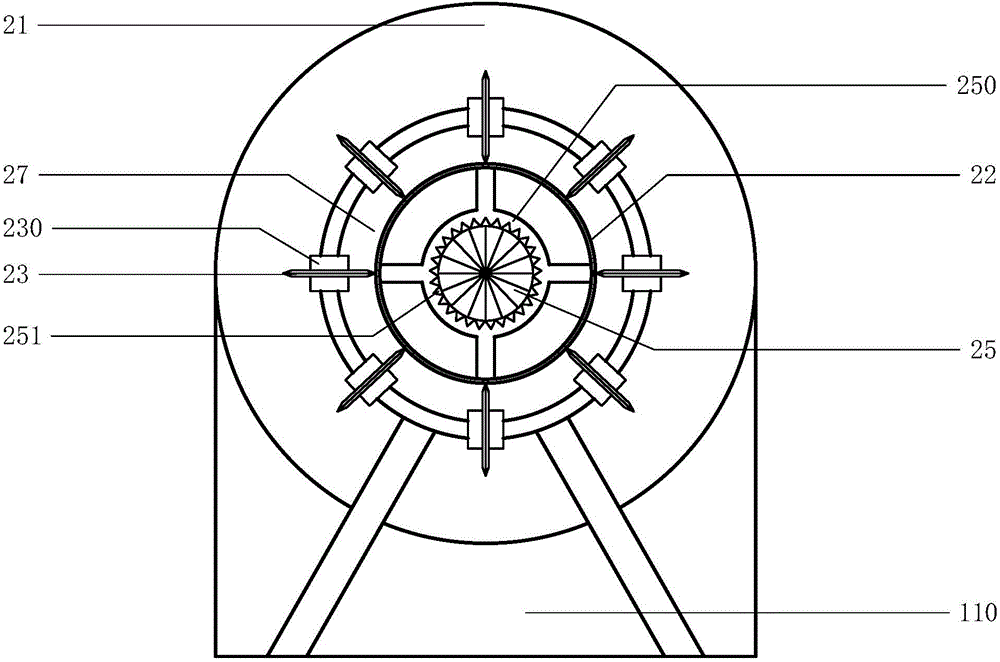

[0021] See attached figure 1 and combine figure 2 , 3 , 4, the moso bamboo strip making machine of the present embodiment comprises top pressure feeder 10 and broken bamboo yellow stripper 20, and described top pressure feeder 10 comprises automatic feed bin 11 and horizontal top press 12, and described automatic feeder The bottom of the silo 11 has a conical structure and is provided with a single discharge pipe 13. The nozzles at both ends of the single discharge pipe 13 communicate with the outside of the automatic feeding silo 11, and the horizontal top press 12 is installed on the automatic feeder. The bottom of the feed bin 11 is also provided with a push arm 14, and the push arm 14 is matched with a single discharge pipe 13; the broken bamboo stripper 20 includes an outer casing frame 21, an inner casing frame 22 , tooth type broken bamboo wheel 23, bamboo yellow peeling knife 24 and bamboo joint crushing head 25, described outer casing frame 21 is arranged on top pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com