Grinding and cutting device of automatic bamboo chopstick production line

A technology of automatic production line and cutting device, applied in the direction of grinding machine, grinding/polishing equipment, special forming/shaping machine, etc., can solve the problem of producing a large amount of bamboo chips and dust, slow processing speed, affecting the production environment and artificial health, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

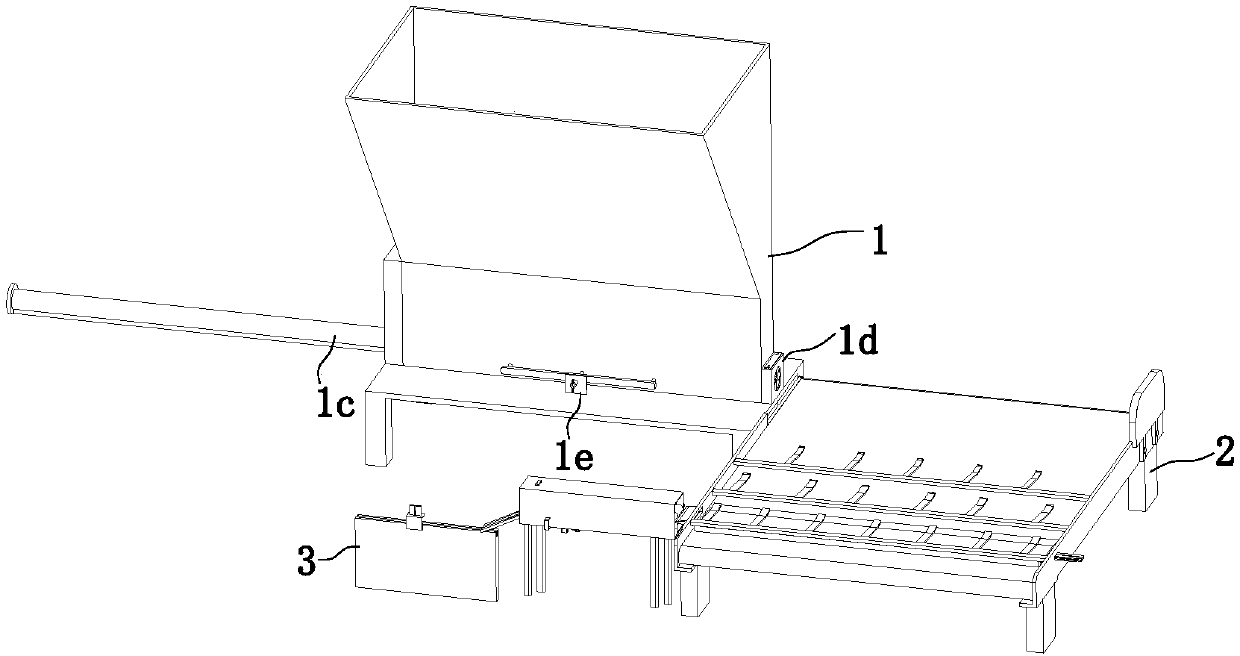

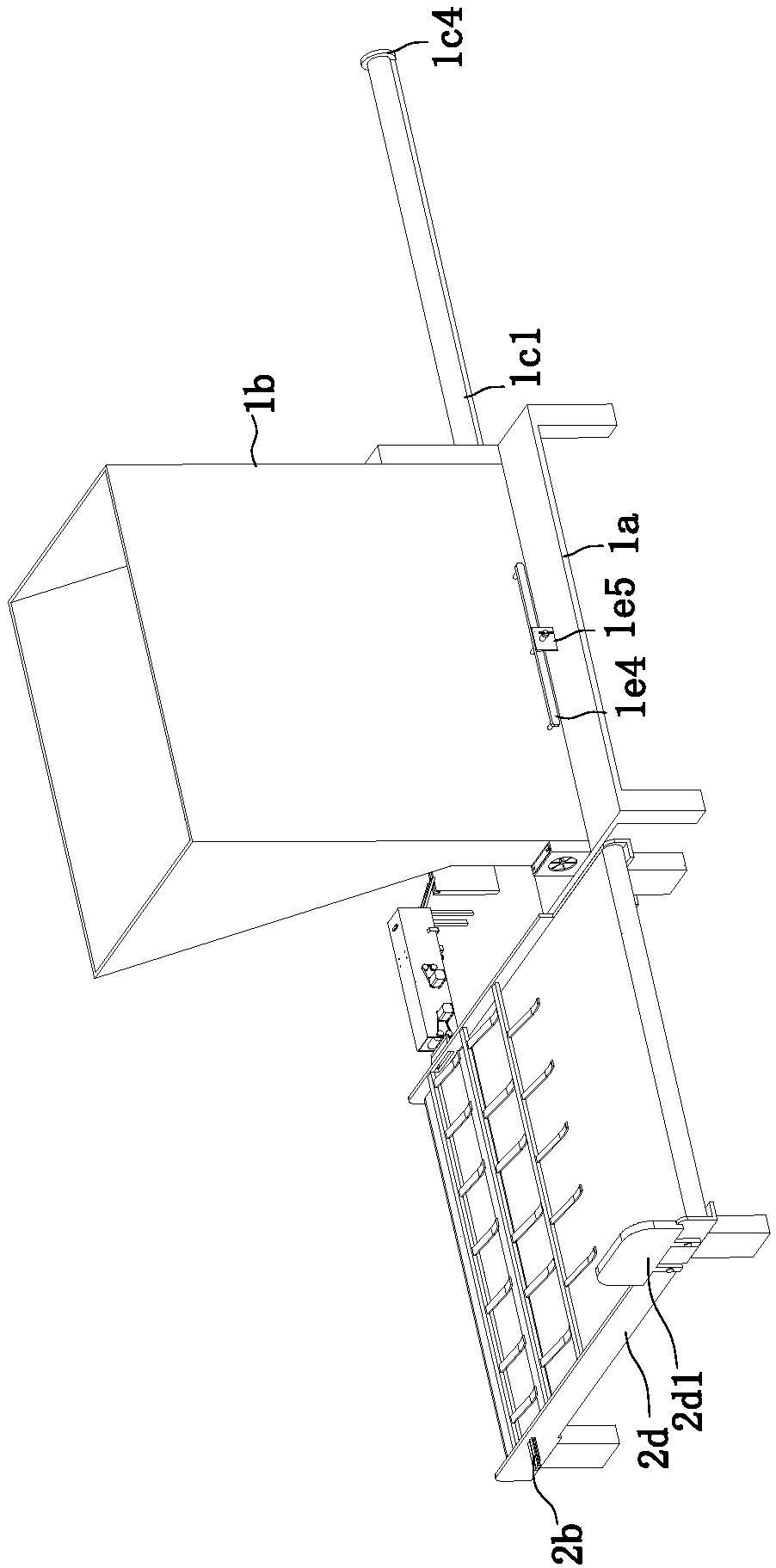

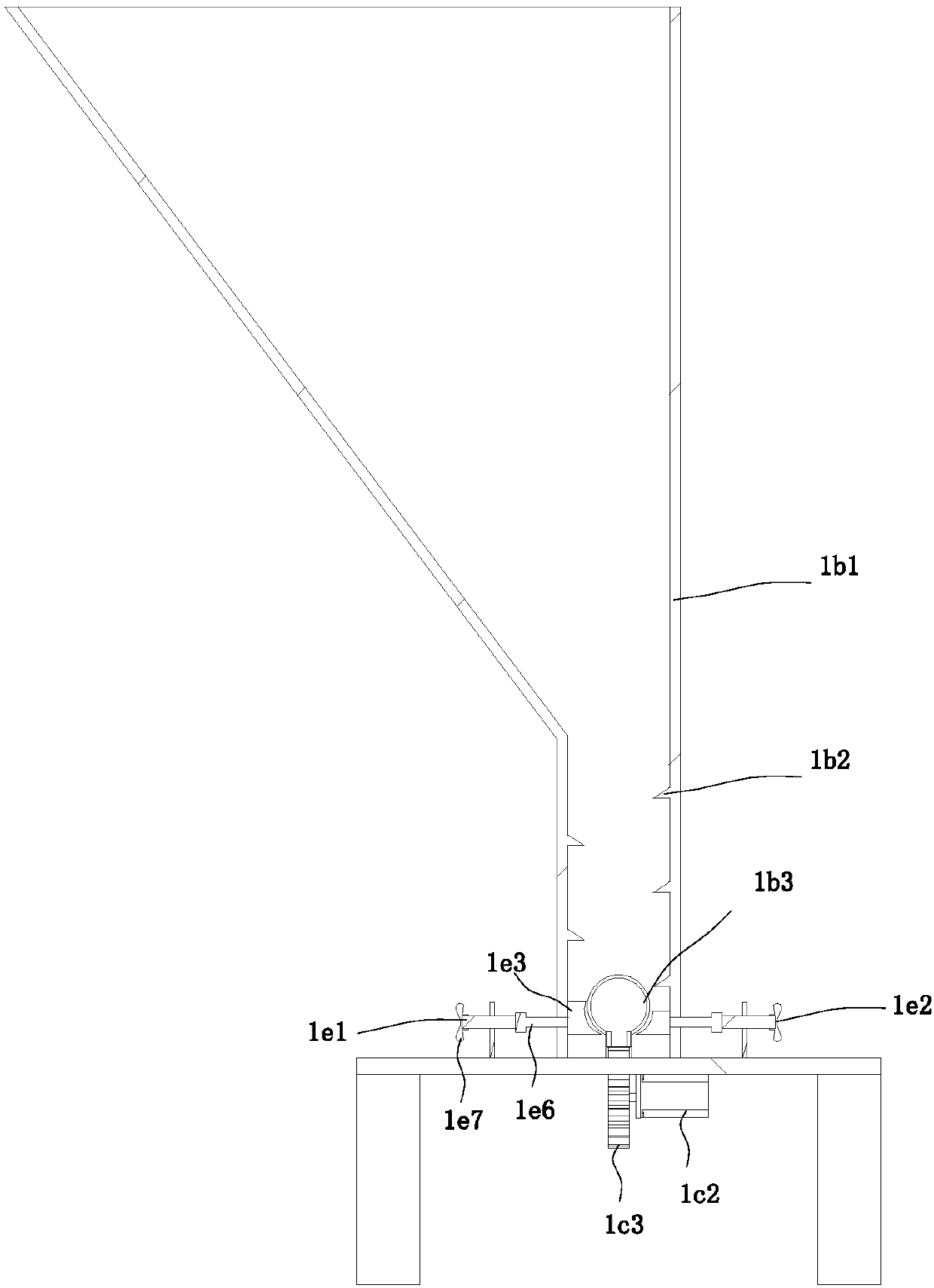

[0031] refer to Figures 1 to 14The shown automatic production line for bamboo chopsticks includes a feeding device 1, a first conveyor belt 2 and a grinding and cutting device 3. The feeding device 1 is located next to the input end of the first conveyor belt 2 and cooperates with the first conveyor belt 2. The grinding and cutting device 3 is positioned at the side of the output end of the first conveyor belt 2 and cooperates with the first conveyor belt 2. The feeding device 1 includes a base 1a, a feed assembly 1b for supporting moso bamboo, and the moso bamboo is fed from the feeder. The pusher assembly 1c that moves to the first conveyor belt 2 in the material assembly 1b and the cutting part 1d that divides the bamboo into bamboo slices, the feed assembly 1b, the pusher assembly 1c and the cutting part 1d are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com