Mechanical equipment for removing bark and kernel of sunflower stalk

A technology of machinery and equipment and sunflower stalks, applied in the field of machinery and equipment, can solve the problems of low production efficiency, low work efficiency, and inability to break sunflower stalks into two halves, and achieve the effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

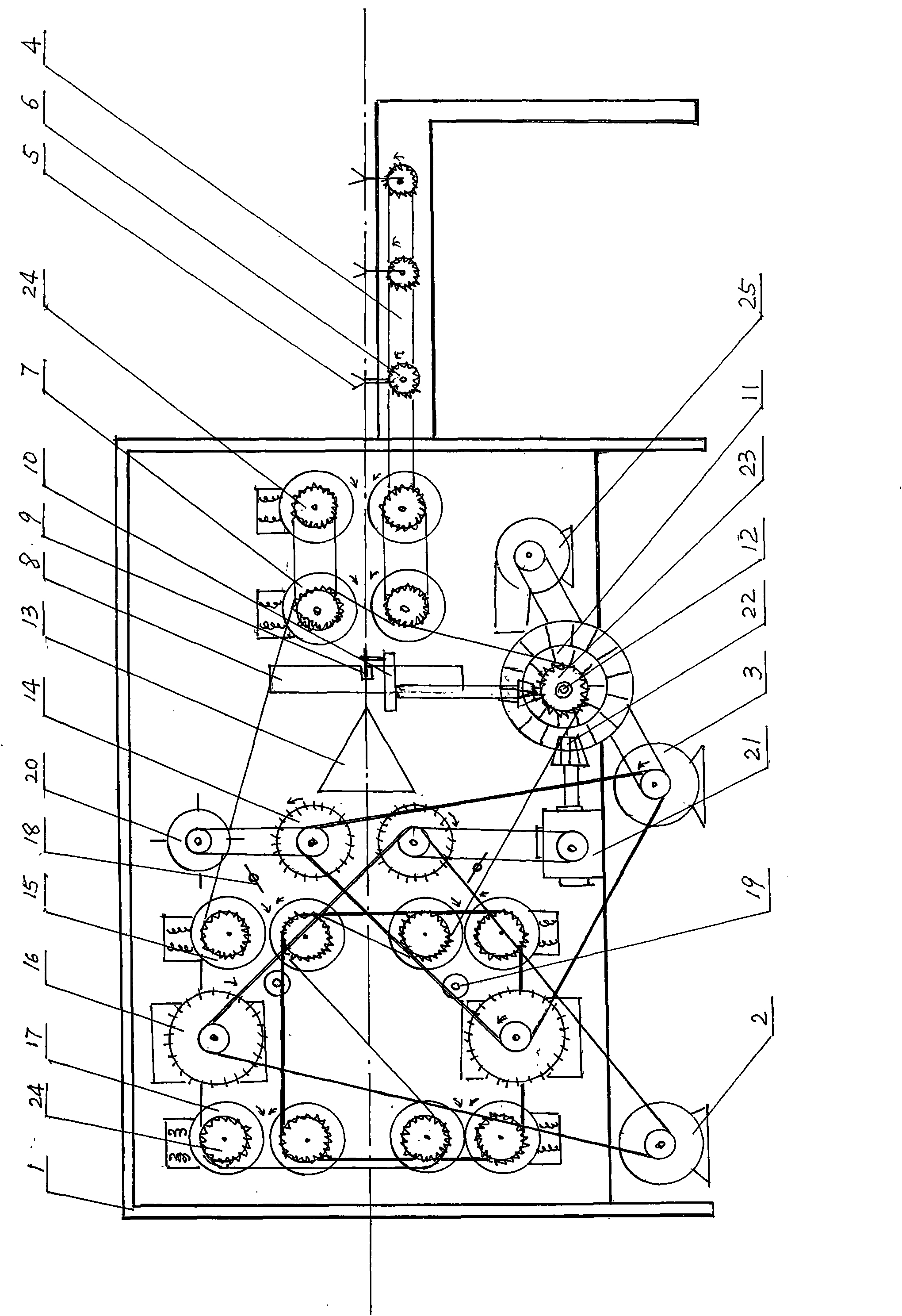

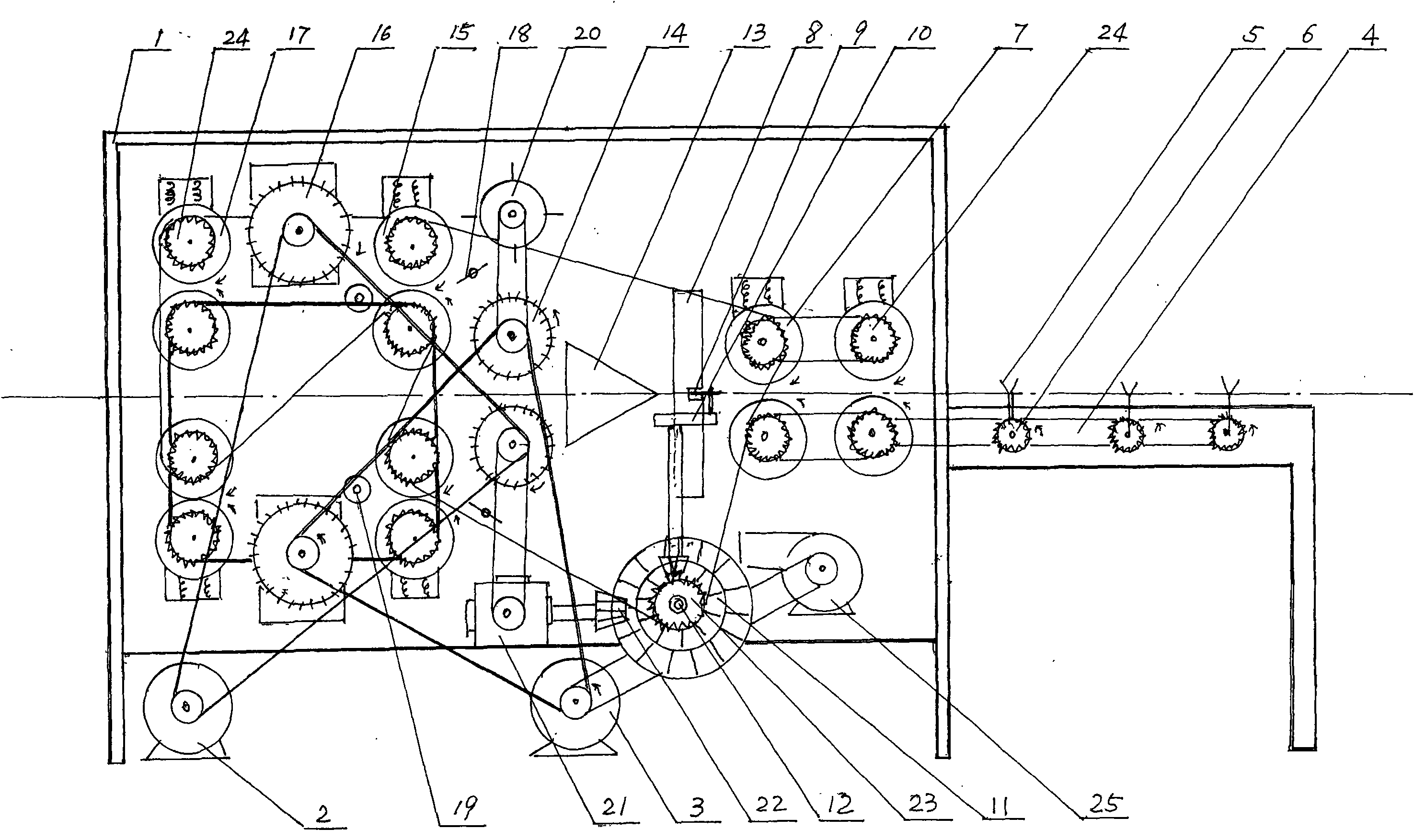

Image

Examples

Embodiment 1

[0014] The frame 4 of the automatic feeding device is installed on the front part of the body 1 of the present invention. Three groups of shift forks 5 are arranged on the frame 4. The shift forks 5 are connected with the wire wheel feed roller 7 through the sprocket wheel 6, and the wire wheel feed roller 7 Set up two groups, two groups of wire wheel feeding rollers 7 are symmetrically installed in the bearing seats on the two side walls of the body 1, springs are installed on the bearing seats, the front end of the wire wheel feeding rollers 7 is provided with a knife rest 8, a knife rest 8 A saw blade 9 capable of reciprocating movement is placed on the top, and a cam 10 is provided at both ends of the saw blade 9. The cam 10 is connected with a group of bevel teeth 11 on the driving shaft 12 through the cam shaft to realize the reciprocating movement of the saw blade 9. The front end of the knife rest 8 is provided with Triangular wedge iron 13, triangular wedge iron 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com