Inner segment removing machine

A technology for removing inner knots and racks, which is used in mechanical equipment, sugarcane machining, plant material machining, etc., and can solve problems such as damage to bamboo meat, high requirements for bamboo shape, and insufficient scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

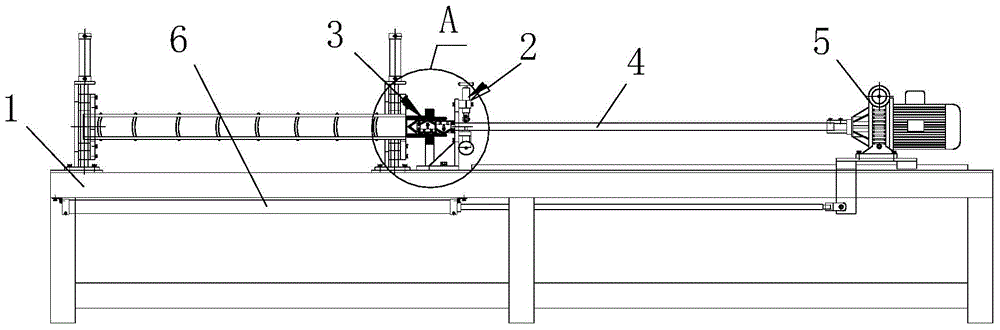

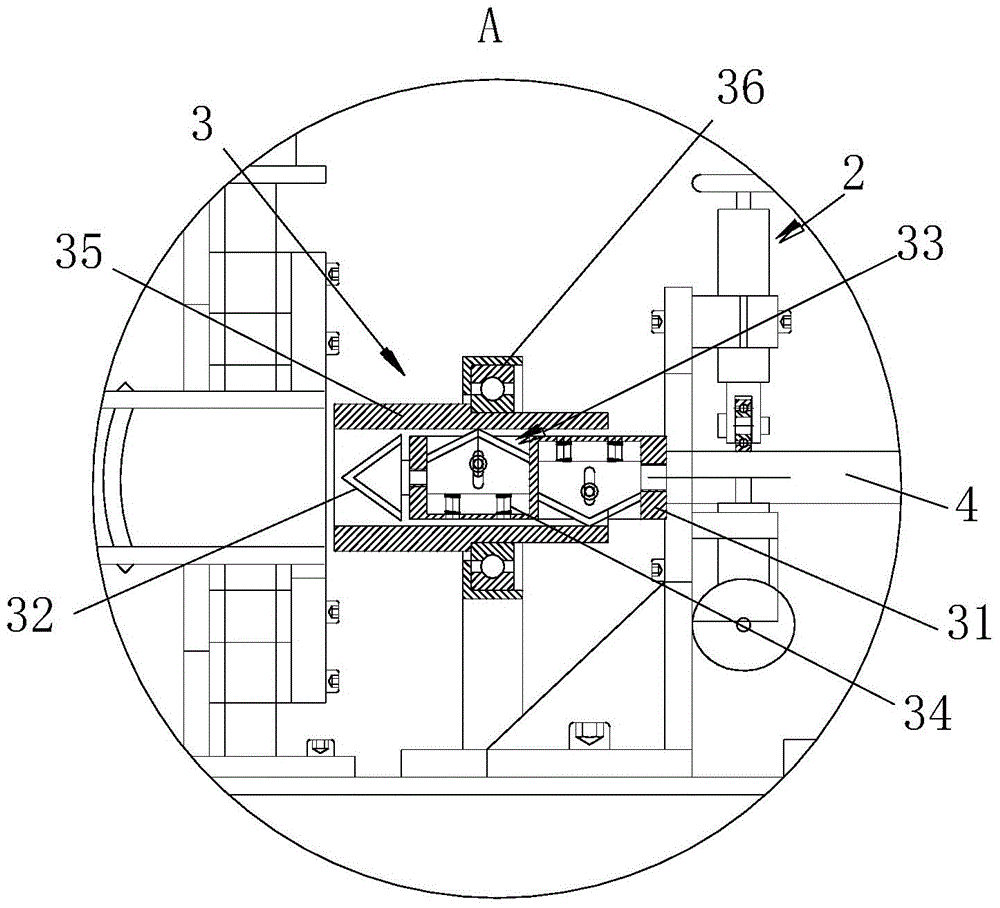

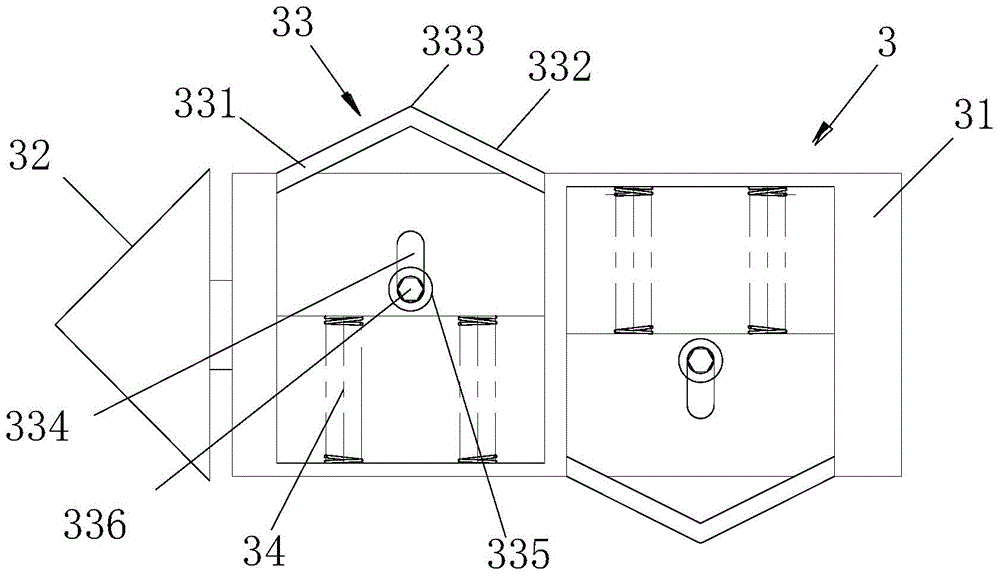

[0028] Such as Figure 1~5 As shown, the present embodiment includes a frame 1, and the frame 1 is provided with a clamping mechanism for clamping bamboo, an internal section scraper assembly 3 for removing the inner section of the clamped bamboo, and an internal section removal tool. The knife shaft 4 coaxially arranged by the scraper assembly 3, the rotating motor 5 for driving the rotation of the knife shaft 4, the positioning mechanism 2 for supporting the knife shaft 4, and the tool for driving the inner section scraper assembly 3 to move toward the clamping mechanism 2 Feed mechanism 6. Wherein, the internal section scraper assembly 3 includes a knife rest 31 fixed with the knife shaft 4, the direction of advancing toward the clamping mechanism 2 with the feed mechanism 6 on the knife rest 31 is the front end or the front, and the direction of retreat is the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com