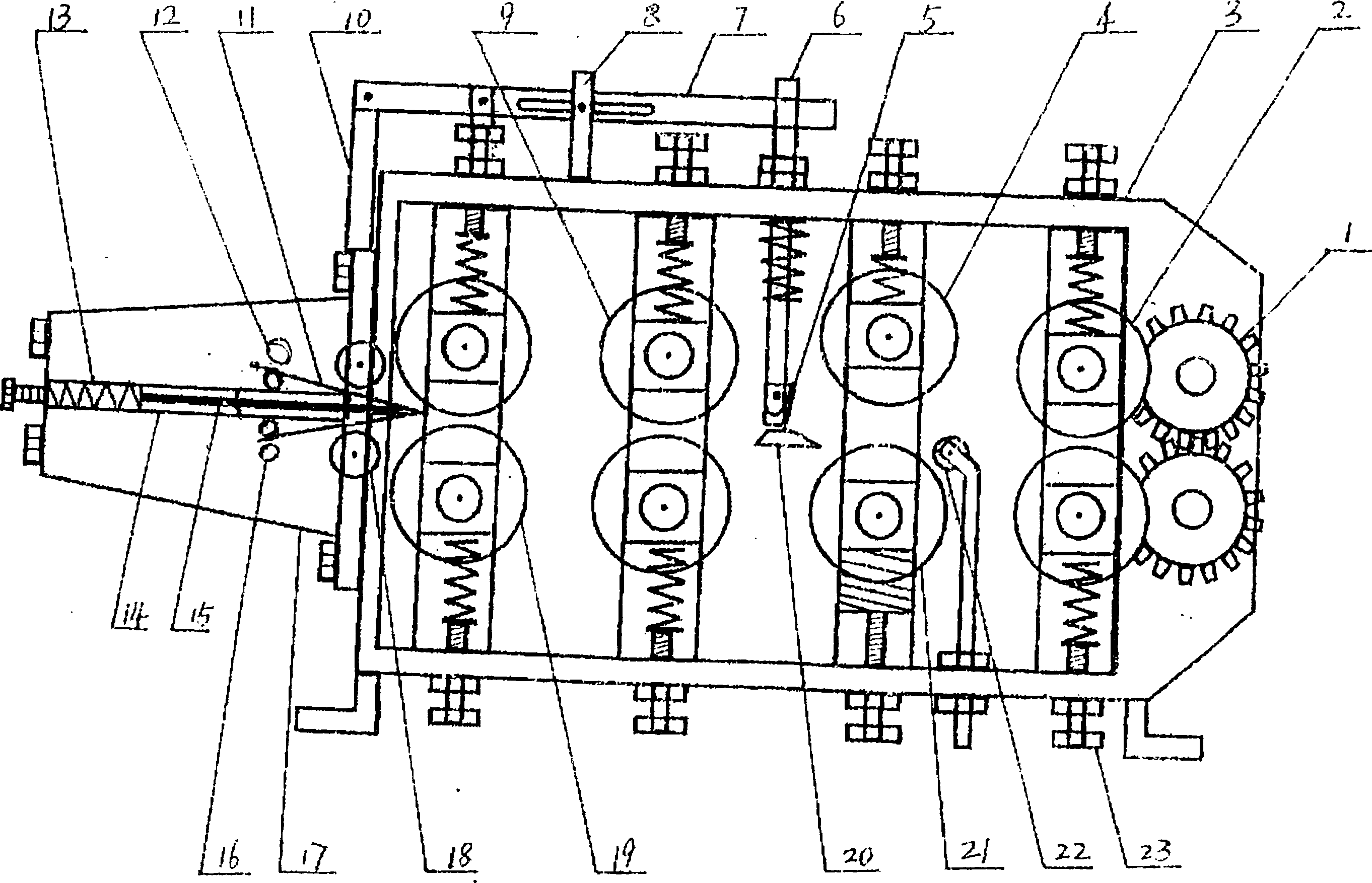

New type thin bamboo strip splitting machine

A technology of cutting machine and bamboo strips, which is applied in the direction of mechanical equipment, thin wood chip manufacturing, sugarcane mechanical processing, etc., can solve the problems of affecting the use of bamboo strips, uneven bamboo strips, and large differences, so as to increase the added value of products and improve Quality requirements, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the implementation of the present invention is further stated:

[0015] The first is to adjust the operating state of the entire equipment so that it can be used for continuous operation.

[0016] Moso bamboo is round, so under normal circumstances, we first break the round moso bamboo into several pieces. Of course, the cross-section of these bamboo pieces will not be a regular square or rectangle, but some irregular shapes. When the end of the bamboo piece enters from the middle of the gear 1, there will be sufficient power to advance to the center of the equipment through the feeding wheel 2. Of course, the gap between the middle of the feeding wheel needs to be adjusted in advance according to the thickness of the bamboo piece. Since the bamboo itself is a slender, flexible material, it will naturally bend and deform in a long space transmission. And in this equipment, when bamboo chip is conveyed to planing wheel aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com