Reciprocating scraping type bamboo green removal device

A technology of bamboo and knife holder, which is applied in the directions of mechanical processing of plant materials, mechanical equipment, sugar cane, etc., can solve the problems of high manual labor intensity, poor safety, and damage to the toughness of bamboo, so as to improve work efficiency and reduce manual labor intensity , the effect of retaining the toughness of bamboo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

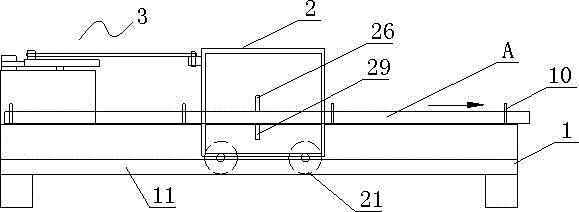

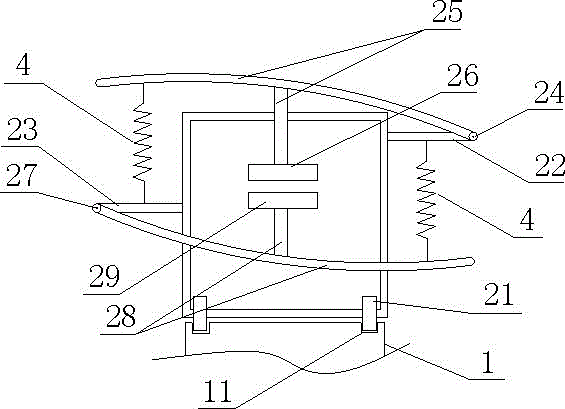

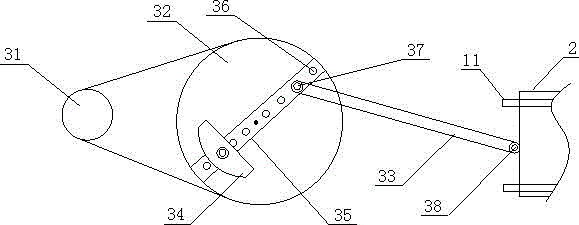

[0022] As shown in the figure (the arrow represents the advancing direction of bamboo A in the figure), the reciprocating scraping type bamboo green removal device of the present invention comprises frame 1, knife rest 2 and knife rest driving mechanism 3, and knife rest 2 is provided with roller 21, The frame 1 is provided with a guide groove 11, and the rollers 21 are movable in the guide groove 11 and can move along the guide groove 11, so that the tool holder 2 can only reciprocate along the direction of the guide groove 11;

[0023] The knife rest 2 is provided with at least one set of blade sets, which include two opposite blades, and the blades are connected with the knife rest 2 through an elastic compression mechanism, so that the two blades in the same blade set Bamboo passing along between the two blades can be clamped. Specifically, the tool rest 2 is provided with an upper crossbeam 22 and a lower crossbeam 23, and one end of the upper crossbeam 22 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com