Glass fiber reinforced ABS (Acrylonitrile Butadiene Styrene) material with high heat resistance

An ABS material, high heat resistance technology, applied in the field of polymer materials, to achieve the effect of expanding the application field, improving heat resistance, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

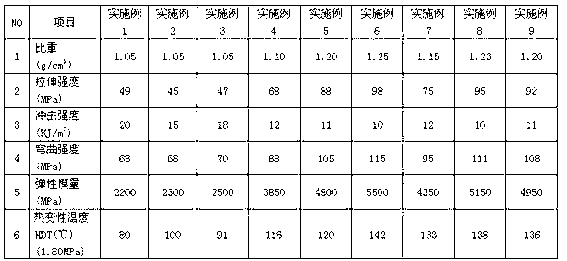

Examples

Embodiment 1( comparative example 1

[0030] 98 parts of ABS, 1 part of antioxidant (mixture of one or more of antioxidant 1010, antioxidant 1076, antioxidant 168, antioxidant 618, antioxidant 300 and antioxidant DSTP), processing aid ( Stearic acid, magnesium stearate and palmitic acid (one or more mixtures) 1 part, added to the high mixer in turn, mixed thoroughly for 3-5 minutes, put into the twin-screw extruder to mix and melt to extrude, and then made the standard Test strips for performance testing.

[0031]

Embodiment 2( comparative example 2

[0033] 88 parts of ABS, 10 parts of heat-resistant agent (a mixture of more than one of N-phenylmaleimide, heat-resistant agent HR-15 and heat-resistant agent MS-NB), antioxidant (antioxidant 1010, anti-oxidant Oxygen 1076, Antioxidant 168, Antioxidant 618, Antioxidant 300 and Antioxidant DSTP) 1 part, processing aid (one of stearic acid, magnesium stearate and palmitic acid Add 1 part of the above mixture) into the high mixer in turn, mix thoroughly for 3-5 minutes, put it into the twin-screw extruder for mixing, melt extrusion, and then make standard test pieces for performance testing.

[0034]

Embodiment 3( comparative example 3

[0036] ABS 93 parts, heat-resistant agent (mixture of more than one of N-phenylmaleimide, heat-resistant agent HR-15 and heat-resistant agent MS-NB) 5 parts, antioxidant 1010, antioxidant Antioxidant 1076, Antioxidant 168, Antioxidant 618, Antioxidant 300 and Antioxidant DSTP) 1 part, processing aid (one of stearic acid, magnesium stearate and palmitic acid 1 part of the above mixture) was added to the high mixer one by one, mixed thoroughly for 3-5 minutes, put into a twin-screw extruder for mixing, melted and extruded, and then standard test pieces were made for performance testing.

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com