Anti-cracking stone-like coating and preparation method thereof

A technology of real stone paint and rutile titanium dioxide, which is applied in coatings and other directions, can solve problems such as poor compatibility, easy cracks, and high proportion of sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: An anti-crack real stone paint, the anti-crack real stone paint is made of raw materials including the parts by weight shown in Table 1. Among them, the dispersant is polyacrylate amine salt dispersant; the wetting agent is glycerin; the defoamer is polydimethylsiloxane; the multifunctional amine additive is AMP-95, and its chemical name is 2-amino-2-methanol base-1-propanol; film-forming aid is alcohol ester dodeca; preservative is 1,2-benzisothiazolin-3-one; thickener is alkali-swellable thickener ASE-60.

[0049]The preparation method of the semi-carbonized fiber comprises the following steps: after the plant fiber is dried, pulverized, and deashed, it is sent into a hypoxic environment, the oxygen content in the hypoxic environment is 0.8%, the temperature of the hypoxic environment is raised to X°C, and the temperature is kept at Zmin. The ignition point of plant fiber is Y°C, the relationship between X and Y is: 10≤(Y-X)≤15, and Z is calculated by th...

Embodiment 2-3

[0055] Embodiment 2-3: An anti-crack real stone paint, the difference from Embodiment 1 is that its raw materials are made of components including the parts by weight shown in Table 1.

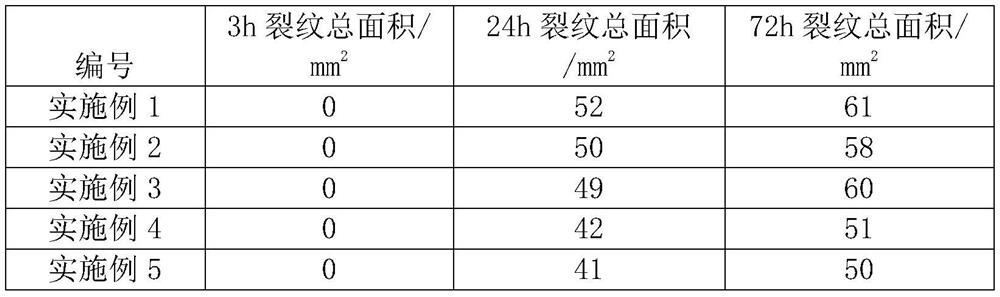

[0056] Each component of raw material and parts by weight thereof in table 1 embodiment 1-3

[0057] components Example 1 Example 2 Example 3 water 100 110 120 Hydroxyethyl cellulose 1 1.5 2 Dispersant 2.5 3 3.5 D 0.6 0.8 1 Defoamer 0.8 1 1.2 Rutile Titanium Dioxide 8 10 12 Ground calcium carbonate 60 50 40 acrylic emulsion 160 170 180 Ethylene glycol 7 8 9 Multifunctional amine additives 1.2 1.5 1.6 Film former 1.8 1.9 2 sand 40 80 120 preservative 2 2.2 2.5 thickener 2 2.5 3 semi carbon fiber 2.5 3 3.5

Embodiment 4

[0058] Embodiment 4: A kind of anti-crack real stone paint, the difference with embodiment 1 is that the preparation method of semi-carbonized fiber comprises the following steps: after the plant fiber is dried, crushed and deashed, it is sent into a hypoxic environment, low The oxygen content in the oxygen environment is 0.2%, raise the temperature of the hypoxic environment to X°C, keep it warm for Zmin, the ignition point of the plant fiber is Y°C, the relationship between X and Y is: 10≤(Y-X)≤15, Z is calculated by the following formula : Z=k(Y-X), k=Y / 400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com