Handmade sausage and making method thereof

A production method and sausage technology, applied in the direction of food science, etc., can solve the problems of unintegrated traditional bacon flavor, not delicate enough to eat, easy to deteriorate or spoilage, etc., and achieve the effect of simple and stable production process, retaining nutrients, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

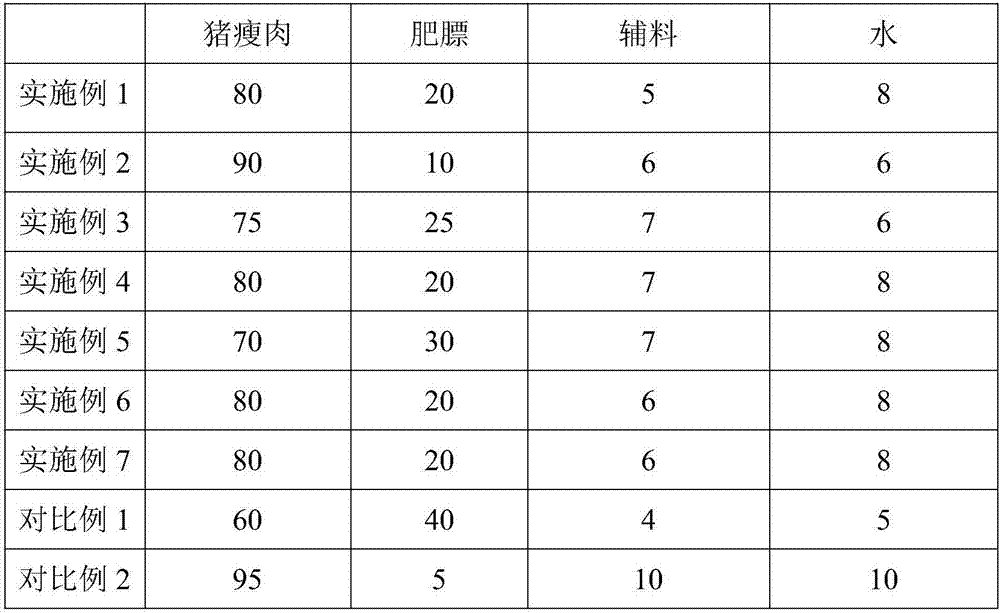

Embodiment 1

[0035] Prepare each component as shown in Table 1, wherein, pickling seasoning comprises 1.5 parts of salt, 1.2 parts of white sugar, 0.5 part of white wine; Basic seasoning includes 0.5 part of salt, 0.5 part of white sugar, 0.5 part of white wine, 0.195 part of monosodium glutamate; Function The additives include 0.1 part of sodium D-isoascorbate and 0.005 part of sodium nitrite.

[0036] The specific production method includes the following steps:

[0037] S1. Raw material pretreatment

[0038] S11. Pre-processing: use fresh hind leg pork as raw material, trim the lean pork by hand to remove the fascia, and cut the lean pork into 15×15×15mm with a dicing machine 3 diced lean meat; put the diced lean meat and marinade seasoning into a blender, stir well, and marinate at 0-4°C for 24 hours to obtain pretreatment raw material A;

[0039] S12. Pretreatment of the fat: cut the fat into 5×5×5mm with a dicing machine 3 diced fat, rinsed with hot water at 60°C for 4 minutes, and...

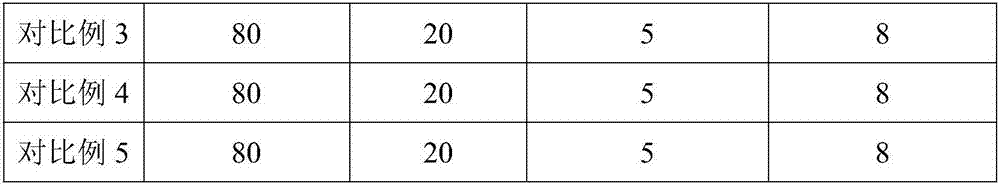

Embodiment 2

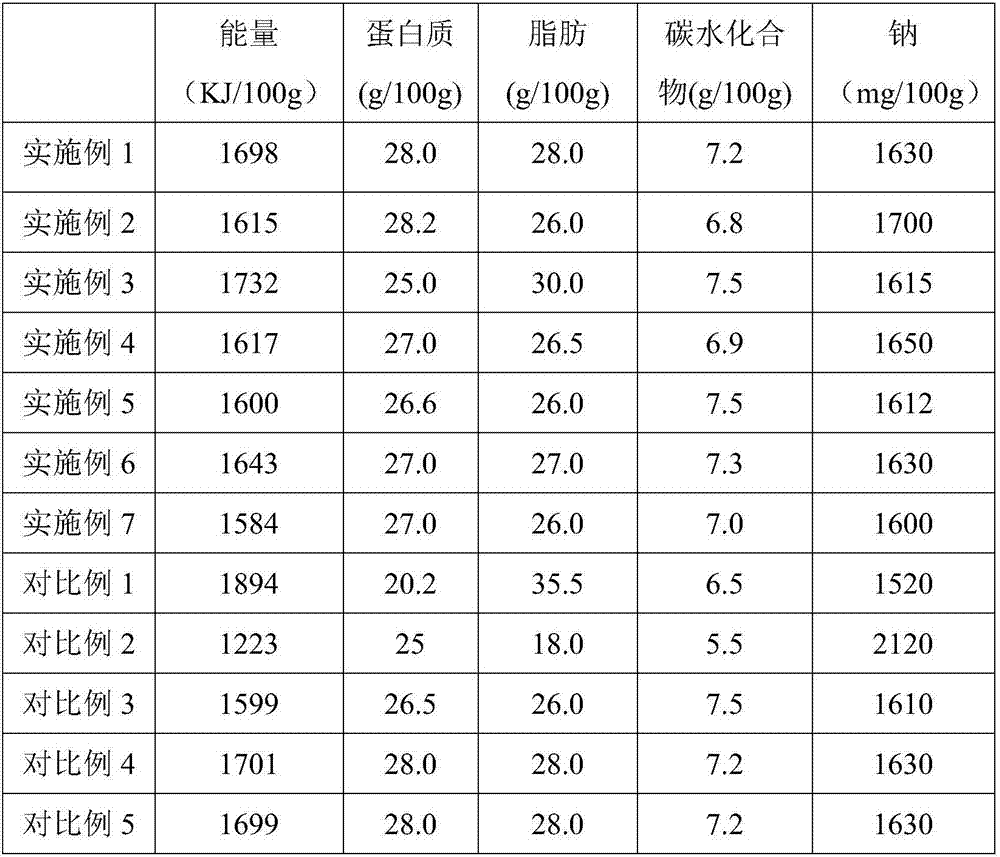

[0044] Different from Example 1, each component of the required weight component is prepared according to Table 1, wherein, the curing seasoning includes 2.0 parts of salt, 1.45 parts of white sugar, and 0.5 part of white wine; the basic seasoning includes 0.5 part of table salt, 0.5 part of white sugar 0.75 parts of liquor, 0.15 parts of monosodium glutamate; functional additives include 0.1 part of sodium D-isoascorbate and 0.005 part of sodium nitrite. The nutritional components of the finished product of the handmade sausage are shown in Table 2.

Embodiment 3

[0046] Different from Example 1, each component of required weight components is prepared according to Table 1, wherein, pickling seasoning comprises 1.992 parts of salt, 1.5 parts of white sugar, 0.75 part of white wine; basic seasoning comprises 0.75 part of salt, 1.0 part of white sugar 0.6 part of liquor, 0.25 part of monosodium glutamate; functional additives include 0.15 part of sodium D-isoascorbate and 0.008 part of sodium nitrite. The nutritional components of the finished product of the handmade sausage are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com