Glass fiber reinforced flame-retardant styrene-acrylonitrile copolymer/ polybutylene terephthalate (AS/ PBT) material and preparation method thereof

A technology of glass fiber and glass fiber, which is applied in the field of polymer processing, can solve the problems of increased material cost, complicated process, and cost provision, and achieve good flame retardancy and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

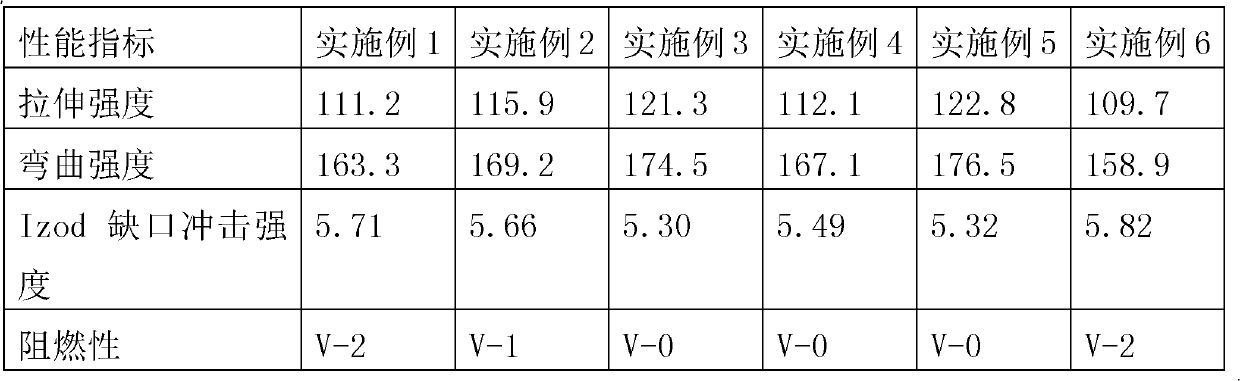

Examples

Embodiment 1

[0037] Embodiment 1: in high-speed mixer, add 55% AS, 10% PBT, 10% FR245, 3% Sb by weight percentage 2 o 3 , 0.3% SN3306, 0.2% antioxidant and 5% compatibilizer are mixed evenly at room temperature, fed into the twin-screw extruder through a precision metering feeder, and added in the fourth temperature zone of the twin-screw extruder 16.5% glass fiber by weight. The length-to-diameter ratio of the twin-screw extruder is 40:1, the temperature of the screw barrel in the 1st to 4th zones is 190 to 200°C, the temperature in the 5th to 9th zones is 210 to 230°C, the temperature of the head is 210°C, and the screw speed is 350~450rpm.

Embodiment 2

[0038] Embodiment 2: in high-speed mixer, add 50% AS, 10% PBT, 10% FR245, 6% Sb by weight percentage 2 o 3 , 0.3% SN3306, 0.5% antioxidant and 5% compatibilizer are mixed evenly at room temperature, fed into the twin-screw extruder through a precision metering feeder, and added in the fourth temperature zone of the twin-screw extruder 18.2% by weight glass fibers. The length-to-diameter ratio of the twin-screw extruder is 40:1, the temperature of the screw barrel in the 1st to 4th zones is 190 to 200°C, the temperature in the 5th to 9th zones is 210 to 230°C, the temperature of the head is 210°C, and the screw speed is 350~450rpm.

Embodiment 3

[0039] Embodiment 3: in high-speed mixer, add 35% AS, 20% PBT, 11% FR245, 7% Sb by weight percentage 2 o 3 , 0.4% SN3306, 0.7% antioxidant and 5% compatibilizer are mixed evenly at room temperature, fed into the twin-screw extruder through a precision metering feeder, and added in the fourth temperature zone of the twin-screw extruder 20.9% glass fiber by weight. The length-to-diameter ratio of the twin-screw extruder is 40:1, the temperature of the screw barrel in the 1st to 4th zones is 190 to 200°C, the temperature in the 5th to 9th zones is 210 to 230°C, the temperature of the head is 210°C, and the screw speed is 350~450rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com