Nano-tungsten alloy material and preparing method thereof

An alloy material and nano-tungsten technology, applied in the field of alloys, can solve the problems of insufficient strength and plasticity of tungsten alloys, difficult to process and form, recrystallization and embrittlement, etc., to reduce sticking balls and walls, improve performance, and increase tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

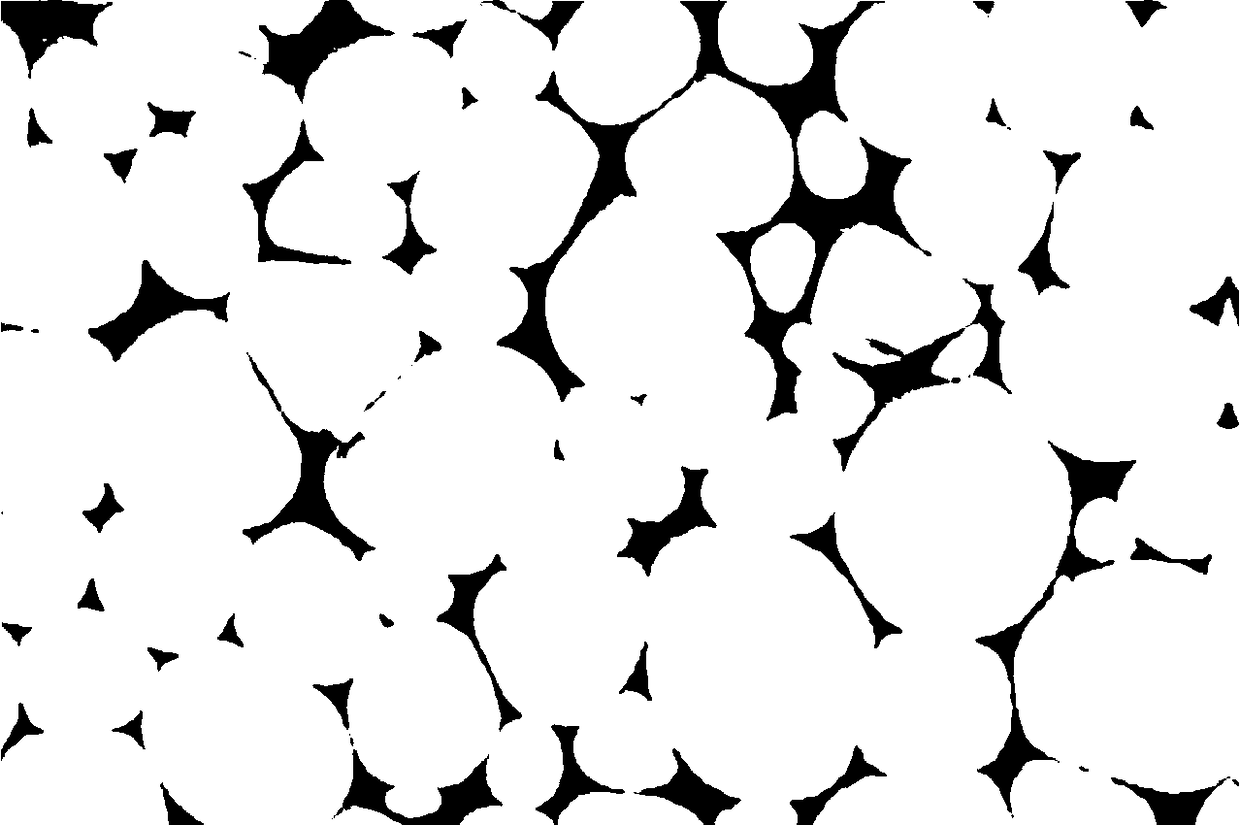

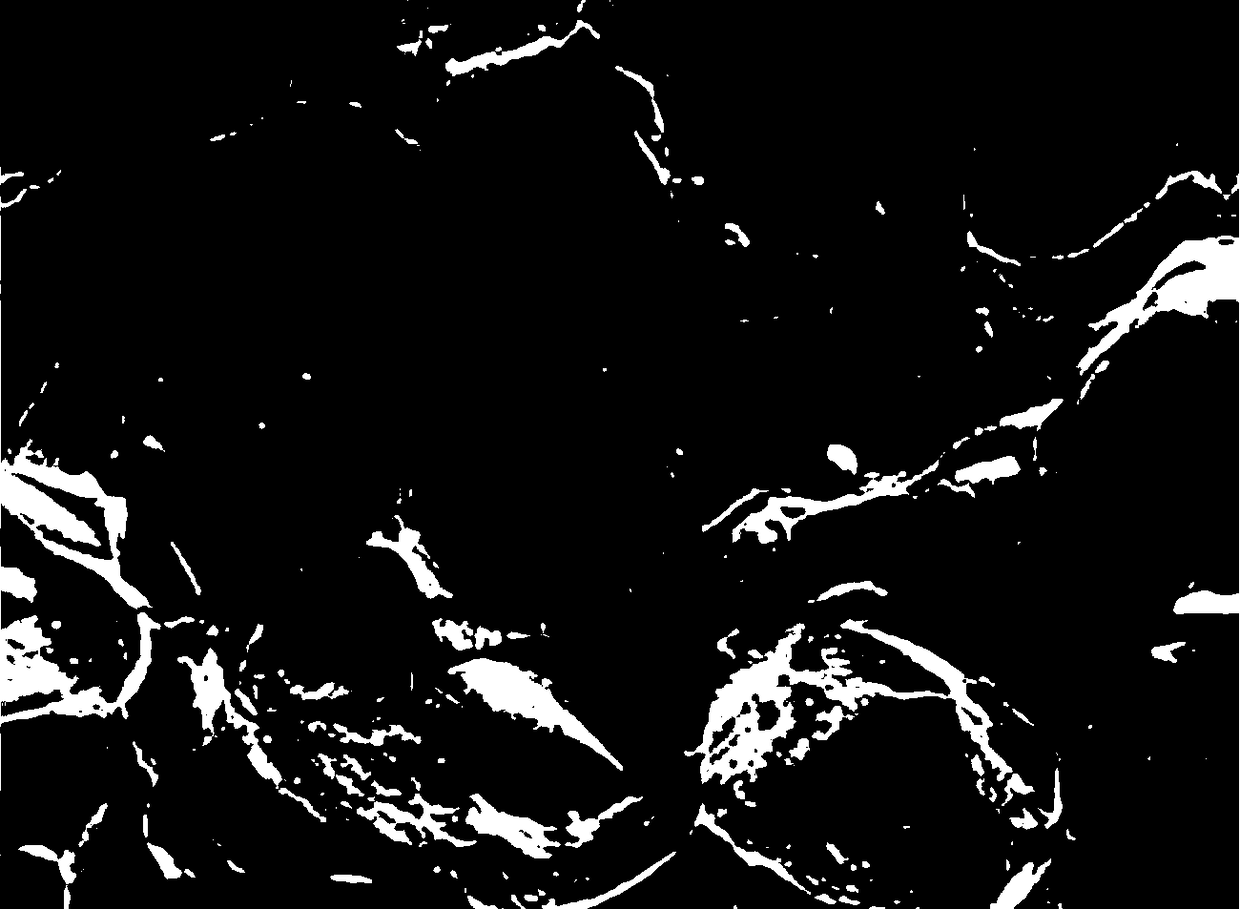

Image

Examples

Embodiment 1

[0022] Raw material: 4.1% Ni, 1.4% Fe, 0.25% Co, 94.25% W.

[0023] Metal tungsten is reduced tungsten powder, Ni powder is carbonyl nickel powder, Fe powder is reduced iron powder, and Co powder is reduced cobalt powder.

[0024] The Fischer particle size of tungsten powder is 2.04 μm, that of carbonyl nickel powder is 2.8 μm, that of reduced iron powder is less than 75 μm, and that of reduced cobalt powder is 1.9 μm.

[0025] Step 1, batching, according to weight percentage 4.1% Ni, 1.4% Fe, 0.25% Co, 94.25% W, carry out proportioning.

[0026] Step 2, ball milling, the metal powder with a good proportion is ball milled in a high-energy ball mill, the ball milling time is 20h, the ball-to-material ratio is 1:2, and argon gas is introduced as a protective atmosphere to make it into ultrafine particles, which can realize atomic mix of sizes;

[0027] Step 3. Mixing materials. Use a three-dimensional mixer to mix evenly. The three-dimensional mixer is especially suitable for ...

Embodiment 2

[0032] Raw materials: 4.5% Ni, 1.56% Fe, 0.32% Co, 93.62% W.

[0033] Metal tungsten is reduced tungsten powder, Ni powder is carbonyl nickel powder, Fe powder is reduced iron powder, and Co powder is reduced cobalt powder.

[0034] The Fischer particle size of tungsten powder is 2.04 μm, that of carbonyl nickel powder is 2.8 μm, that of reduced iron powder is less than 75 μm, and that of reduced cobalt powder is 1.9 μm.

[0035] Step 1, batching, according to weight percentage 4.1% Ni, 1.4% Fe, 0.32% Co, 93.62% W, carry out proportioning.

[0036] Step 2, ball milling, the metal powder with a good proportion is ball milled in a high-energy ball mill, the ball milling time is 20h, the ball-to-material ratio is 1:2, and argon gas is introduced as a protective atmosphere to make it into ultrafine particles, which can realize atomic mix of sizes;

[0037] Step 3. Mixing materials. Use a three-dimensional mixer to mix evenly. The three-dimensional mixer is especially suitable fo...

Embodiment 3

[0042] Raw materials: 4.55% Ni, 1.95% Fe, 0.5% Co, 93% W.

[0043] Metal tungsten is reduced tungsten powder, Ni powder is carbonyl nickel powder, Fe powder is reduced iron powder, and Co powder is reduced cobalt powder.

[0044] The Fischer particle size of tungsten powder is 2.04 μm, that of carbonyl nickel powder is 2.8 μm, that of reduced iron powder is less than 75 μm, and that of reduced cobalt powder is 1.9 μm.

[0045] Step 1, batching, according to weight percentage 4.55% Ni, 1.95% Fe, 0.5% Co, 93% W, carry out proportioning.

[0046]Step 2, ball milling, the metal powder with a good proportion is ball milled in a high-energy ball mill, the ball milling time is 20h, the ball-to-material ratio is 1:2, and argon gas is introduced as a protective atmosphere to make it into ultrafine particles, which can realize atomic mix of sizes;

[0047] Step 3. Mixing materials. Use a three-dimensional mixer to mix evenly. The three-dimensional mixer is especially suitable for mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com