Acellular cornea or acellular corneal stroma, preparation method and application thereof

A corneal stroma, decellularization technology, applied in the field of medical materials, can solve the problems of opaque tensile strength, low light transmittance, long decellularization time, etc., and achieve the effect of retaining transparency, short processing time, and low immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

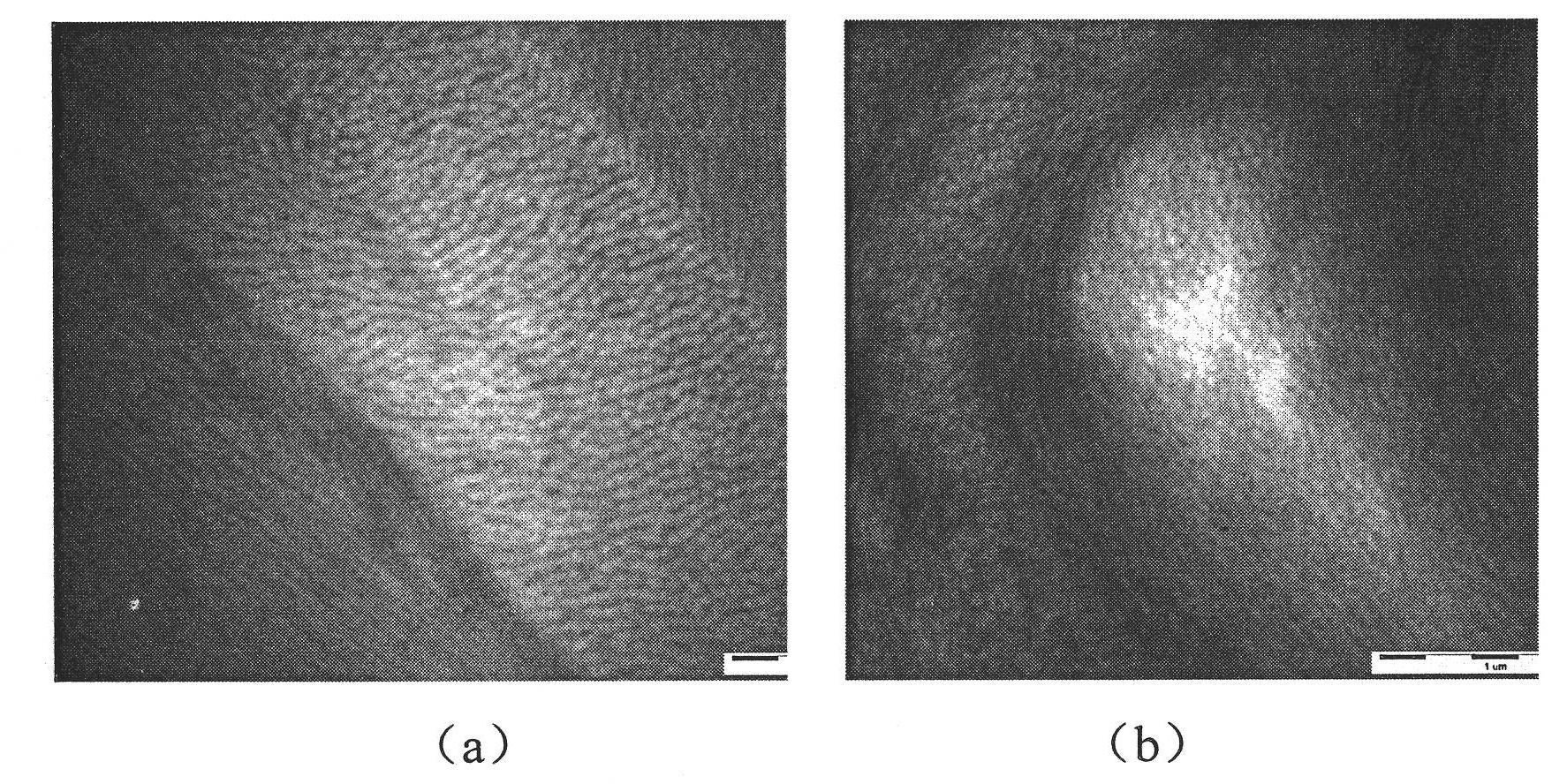

[0036] Example 1: Preparation of porcine full-thickness cornea decellularized cornea

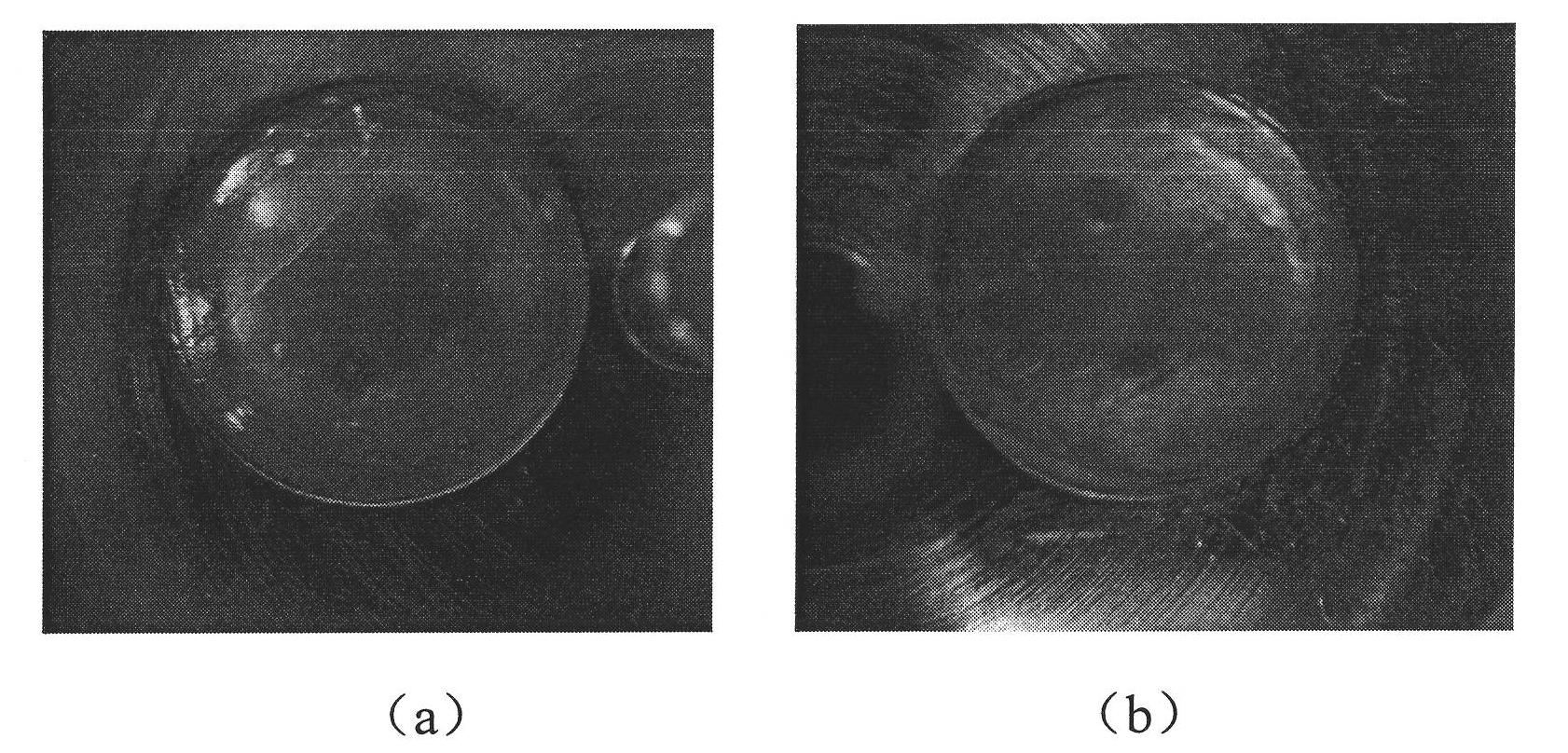

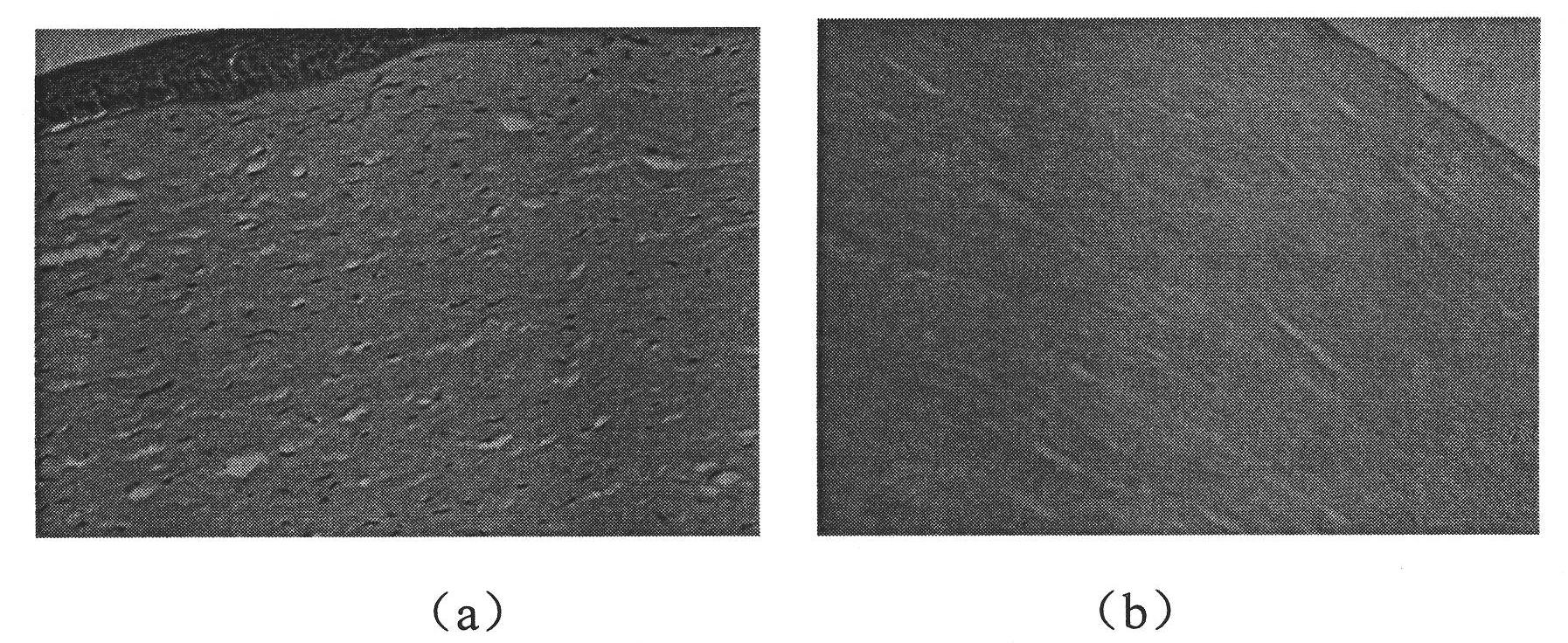

[0037] (1) Acquisition of fresh porcine cornea: obtain fresh porcine eyeballs from pig carcasses slaughtered in a certain slaughterhouse, and use phosphate buffered saline (PBS, pH value) containing 2000u / ml of gentamicin after trimming the eyeball surface accessory tissues 7) wash 3 times, and cut out the full-thickness pig cornea along the corneal limbus under the operating microscope, see figure 1 a. figure 2 a. image 3 a: The initial weight of the obtained porcine full-thickness cornea is weighed under the condition of the full-thickness cornea at room temperature of 20°C to 28°C;

[0038] (2) Remove corneal epithelium, endothelium and stromal cells:

[0039] ① Soak the obtained porcine full-thickness cornea in pure water for 0.5 h at room temperature;

[0040] ② Put each piece of pig full-thickness cornea treated in step ① into 10ml 200U / ml phospholipase A 2 solution, placed on a...

Embodiment 2

[0047] Example 2: Preparation of porcine corneal stroma decellularized matrix

[0048] (1) Acquisition of fresh porcine corneal stroma: obtain fresh porcine eyeballs from pig carcasses slaughtered in a certain slaughterhouse, and use phosphate buffered saline (PBS, pH The value is 8) Washing 4 times, cutting the porcine full-thickness cornea along the corneal limbus under the operating microscope; scraping off the corneal epithelium and tearing off the descemet layer from the porcine full-thickness cornea to obtain the porcine corneal stroma; room temperature 20 ° C ~ 28 ° C Next, the obtained porcine corneal stroma was weighed for initial initial weight;

[0049] (2) Remove corneal stromal cells:

[0050] ①At room temperature (20°C-28°C), soak the obtained porcine corneal stroma in pure water for 0.5h;

[0051] ② Put each piece of porcine corneal stroma after step ① into 15ml 300U / ml phospholipase A 2 solution, placed on a constant temperature shaker for 3 hours, the treat...

Embodiment 3

[0055] Example 3: Preparation of bovine full-thickness cornea decellularized cornea

[0056] (1) Acquisition of fresh bovine full-thickness cornea: obtain fresh bovine eyeballs from cattle carcasses slaughtered in a certain slaughterhouse, and use 2000u / ml gentamicin-containing phosphate buffered saline (PBS, The pH value is 7.5) and washed 5 times, and the whole cornea was cut along the limbus under an operating microscope to obtain a bovine full-thickness cornea; at a room temperature of 20°C to 28°C, the initial weight of the obtained bovine full-thickness cornea was weighed;

[0057] (2) Remove corneal epithelium, endothelium and stromal cells:

[0058] ①At room temperature (20°C-28°C), soak the obtained bovine cornea in pure water for 1 hour;

[0059] ② Put each piece of bovine full-thickness cornea treated in step ① in 15ml 2.4U / ml neutral protease Dispase II solution, place it on a constant temperature shaker and digest it for 5 hours with shaking, the treatment temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com