Highly quantitative soft facial tissues and production method thereof

A production method and high quantitative technology, applied in papermaking, textiles and papermaking, natural cellulose pulp/paper, etc., can solve problems such as difficulty in improving softness, achieve high quantitative, retain toughness and absorbency, and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

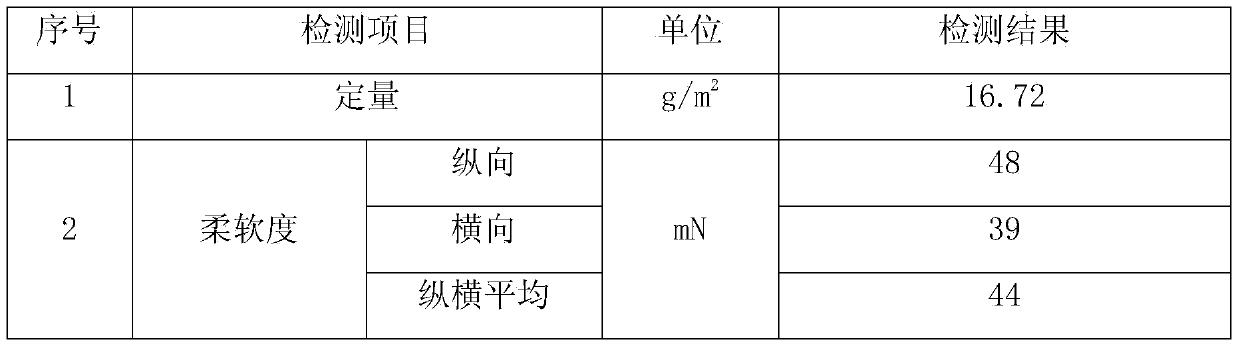

Embodiment 1

[0022] The technical scheme adopted in the present invention is as follows: a kind of production method of the ultra-soft paper face towel of high quantitative, comprises following process according to production process:

[0023] 1) Pulping:

[0024] Coniferous wood: broad-leaved wood = 30%: 70%, the degree of percussion of coniferous wood after pulping is 22-25 0 Sr. The broad-leaved wood does not need to be pulped, and medium-concentrated pulping is sufficient. 16-18Kg of softener is added per ton of pulp, and the softener is an imidazoline compound.

[0025] 2) Sizing:

[0026] The equipment needed for the sizing process includes: the paper machine of the crescent former and the feed pump, etc.

[0027] The paper machine adopts a crescent shaper and adopts a stepped diffusion method. The pulp is divided into two layers to ensure the hand feeling and toughness. Add a wet strength agent to the inlet of the feeding pump, the wet strength agent is polyacrylamide, and the a...

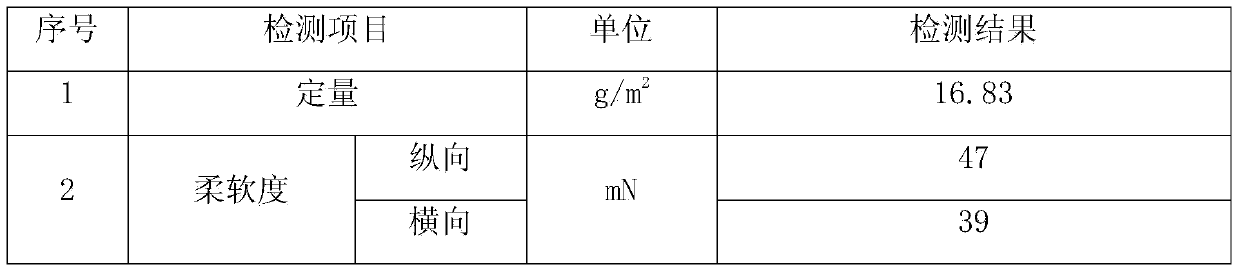

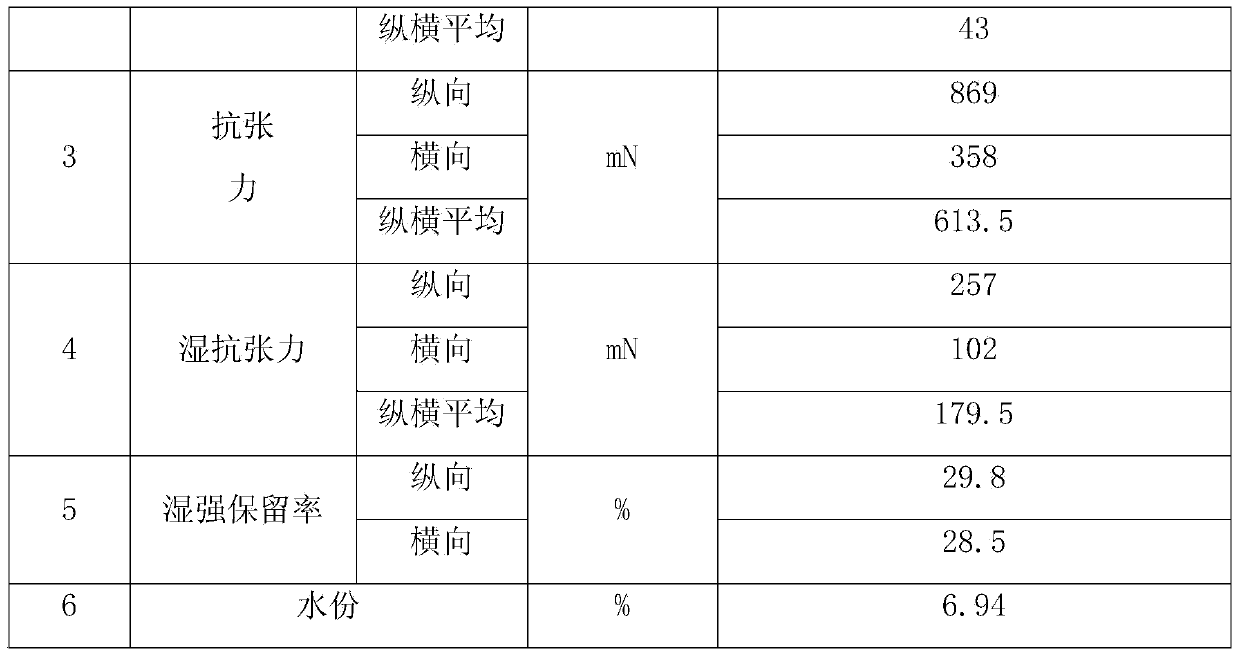

Embodiment 2

[0036] The technical scheme adopted in the present invention is as follows: a kind of production method of the ultra-soft paper face towel of high quantitative, comprises following process according to production process:

[0037] 1) Pulping:

[0038] Coniferous wood: broad-leaved wood = 32%: 68%, the degree of percussion of coniferous wood after pulping is 22-25 0 Sr. Broad-leaved wood does not need to be pulped, and medium-concentrated pulping is sufficient. When pulping, 14-16 kg of softening agent is added per ton of slurry, and the softening agent is an imidazoline compound.

[0039] 2) Sizing:

[0040] Using a crescent shaper, stepped diffusion, the slurry is divided into two layers to ensure the feel and toughness. Add a wet strength agent to the inlet of the feeding pump, the wet strength agent is polyacrylamide, and the amount added is 8-13kg / ton of paper. The pulp-net speed ratio is 0.92-0.95.

[0041] 3) Dehydration & Drying:

[0042] The wet paper sheet is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com