Soft non-woven fabric laminated PVC resin foaming film and preparation method and application thereof

A PVC resin, non-woven technology, applied in synthetic resin layered products, applications, other household appliances, etc., can solve the problems of non-tensile, non-slip, and non-cold-resistant sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

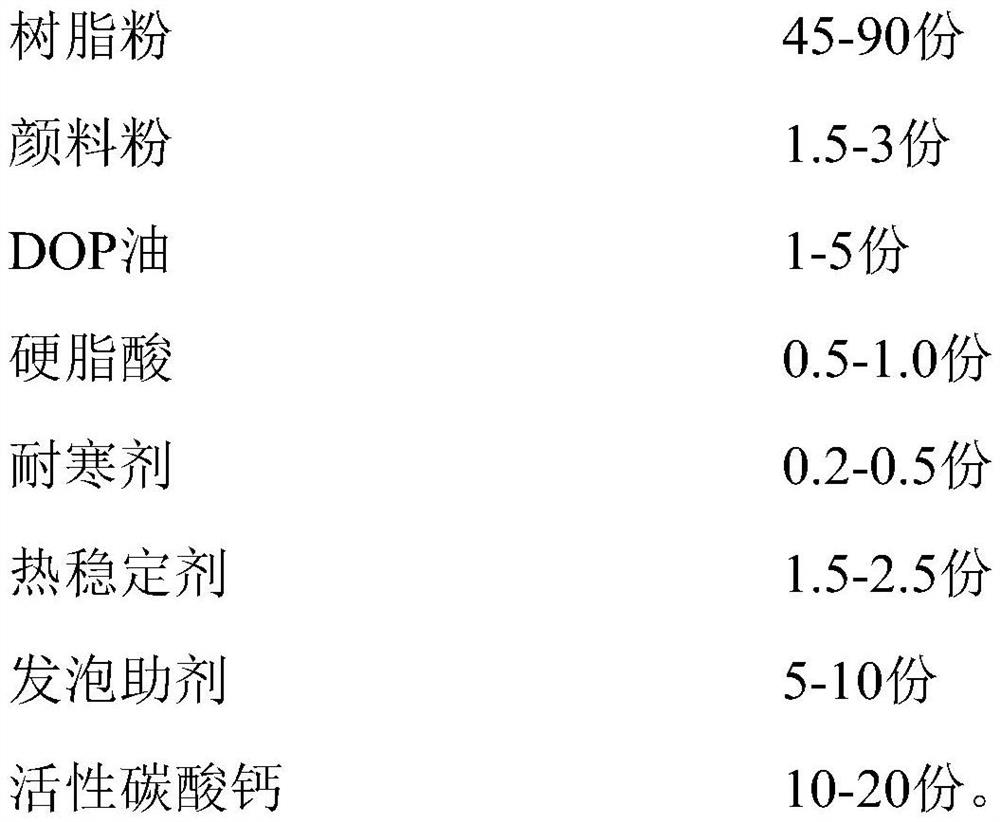

[0037] A soft non-woven fabric laminated PVC resin foam film, comprising the following raw materials in parts by weight:

[0038]

[0039]

[0040] The active calcium carbonate is nano active calcium carbonate treated with maleic anhydride grafted styrene isoprene-styrene block copolymer.

[0041] Each part of the resin powder is PVC resin powder; each part of the PVC resin powder is composed of 1125PVC paste resin powder, PVC paste resin powder WB-33 and PVC resin powder-1311 in a weight ratio of 0.8:1.0:0.6 mixture.

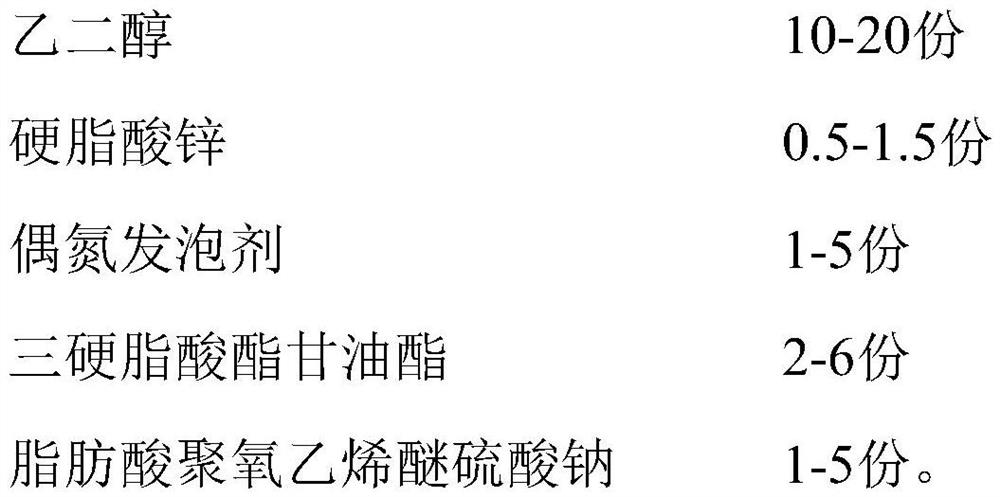

[0042] Every part of described foaming aid comprises the raw material of following weight part:

[0043]

[0044]Each part of the azo blowing agent is a mixture of azodimethylamine and azobisisobutyronitrile in a weight ratio of 0.8:1.0.

[0045] Described foaming aid is made through the following steps:

[0046] S1. According to parts by weight, mix azo foaming agent, zinc stearate and ethylene glycol, heat to 70°C, and stir at a speed of 300r / min ...

Embodiment 2

[0059] A soft non-woven fabric laminated PVC resin foam film, comprising the following raw materials in parts by weight:

[0060]

[0061] The active calcium carbonate is nano active calcium carbonate treated with maleic anhydride grafted styrene isoprene-styrene block copolymer.

[0062] Each part of the resin powder is PVC resin powder; each part of the PVC resin powder is composed of 1125PVC paste resin powder, PVC paste resin powder WB-33 and PVC resin powder-1311 in a weight ratio of 0.85:1.0:0.7 mixture.

[0063] Every part of described foaming aid comprises the raw material of following weight part:

[0064]

[0065] Each part of the azo foaming agent is a mixture of azodimethylamine and azobisisobutyronitrile in a weight ratio of 0.85:1.0.

[0066] Described foaming aid is made through the following steps:

[0067] S1. According to parts by weight, mix azo foaming agent, zinc stearate and ethylene glycol, heat to 73°C, stir at a speed of 325r / min for 68min to ...

Embodiment 3

[0080] A soft non-woven fabric laminated PVC resin foam film, comprising the following raw materials in parts by weight:

[0081]

[0082] The active calcium carbonate is nano active calcium carbonate treated with maleic anhydride grafted styrene isoprene-styrene block copolymer.

[0083] Each part of the resin powder is PVC resin powder; each part of the PVC resin powder is composed of 1125PVC paste resin powder, PVC paste resin powder WB-33 and PVC resin powder-1311 in a weight ratio of 0.9:1.0:0.8 mixture.

[0084] Every part of described foaming aid comprises the raw material of following weight part:

[0085]

[0086] Each part of the azo blowing agent is a mixture of azodimethylamine and azobisisobutyronitrile in a weight ratio of 0.9:1.0.

[0087] Described foaming aid is made through the following steps:

[0088] S1. According to parts by weight, mix azo foaming agent, zinc stearate and ethylene glycol, heat to 75°C, and stir at a speed of 350r / min for 75min t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com