Electric dust removal control system and control method thereof

A control system, electrostatic precipitator technology, applied in electrical program control, comprehensive factory control, electrostatic separation, etc., can solve problems such as easy explosion, and achieve the effects of less power consumption, easy maintenance, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

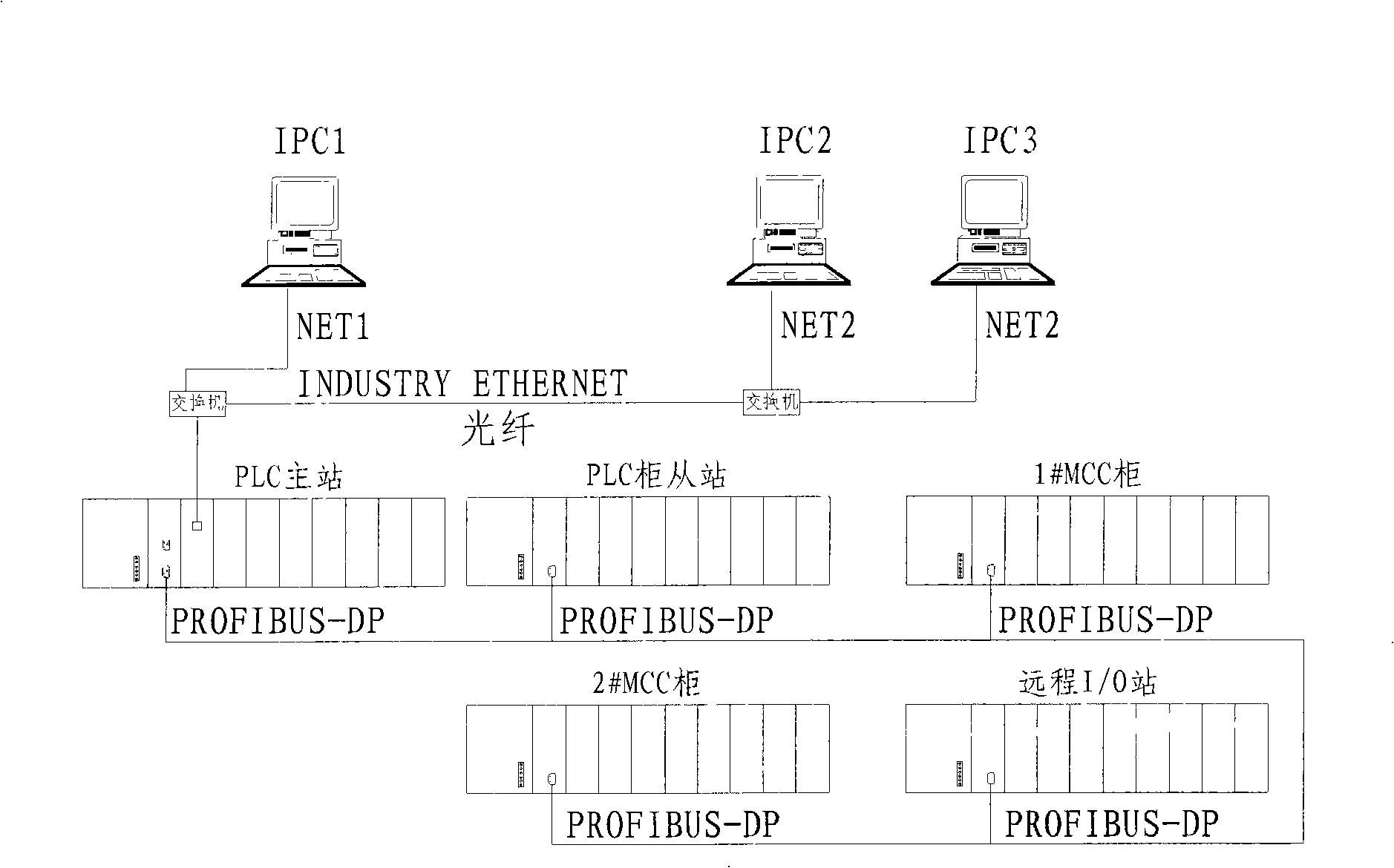

[0021] In recent years, the use of PLC network technology to realize distributed sampling has become a consensus, that is, a set of sampling units is set up near the controlled point, and the state sampling and control output of the controlled point are completed nearby, and the sampling units are connected through an industrial control network to form a The lower computer system of the monitoring system. The network can form a redundant network according to user needs, and can fully meet the needs of on-site sampling technically. The operator station and engineer station with monitoring function use graphical monitoring terminals to complete the centralized monitoring, data analysis, unified scheduling and management of the controlled equipment. For communication between the operation station and the lower computer, an industrial control network can be selected to form a local monitoring system, or a telephone communication line, wireless transmission network, etc. can be sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com