Filter-cloth curved-stretching rapping mechanism of pressure filter and rapping method

A technology of filter press and filter cloth, applied in the field of filter press manufacturing, which can solve the problems of low efficiency, waste of filter cloth, and difficulty in scraping clean, etc., and achieve the effect of high efficiency and avoiding unclean scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

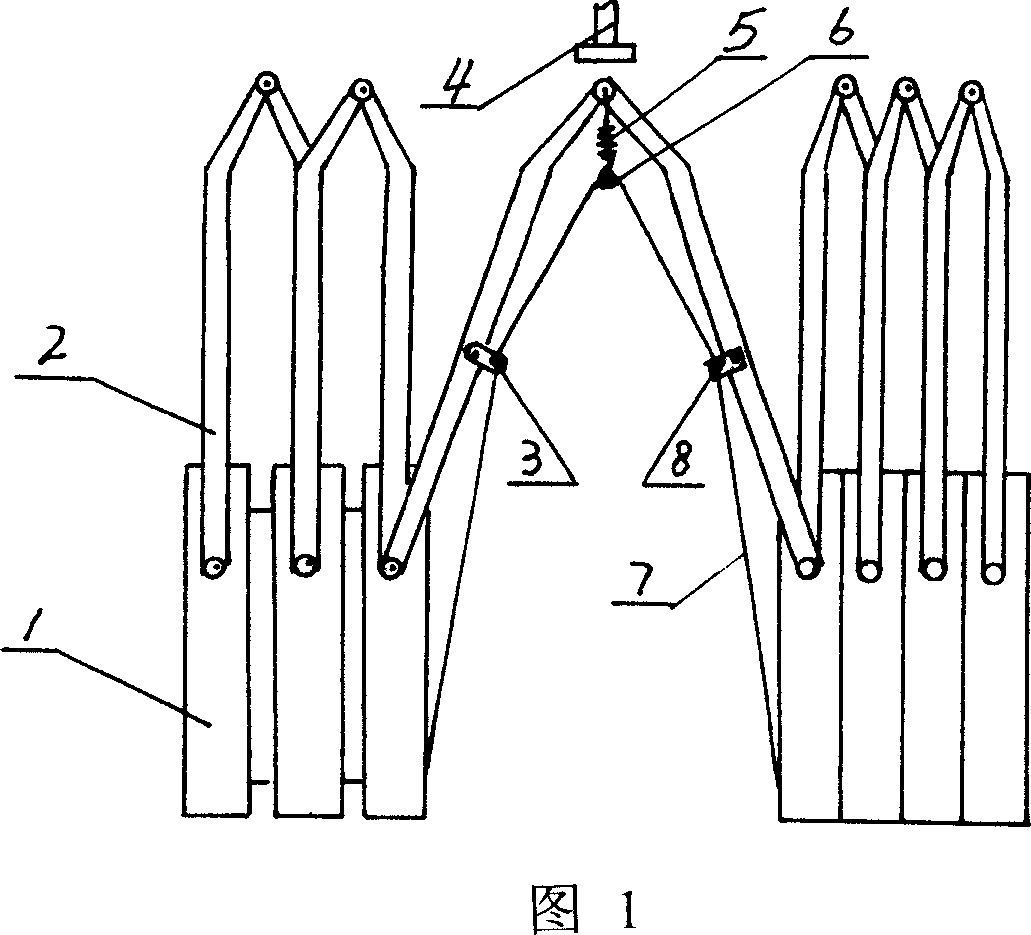

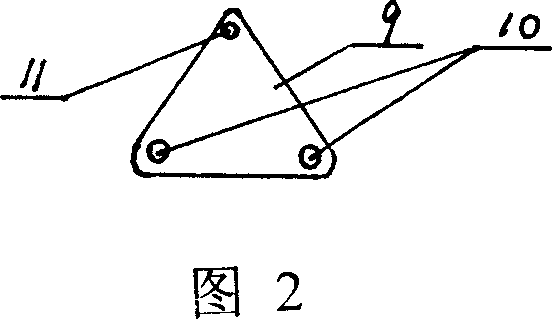

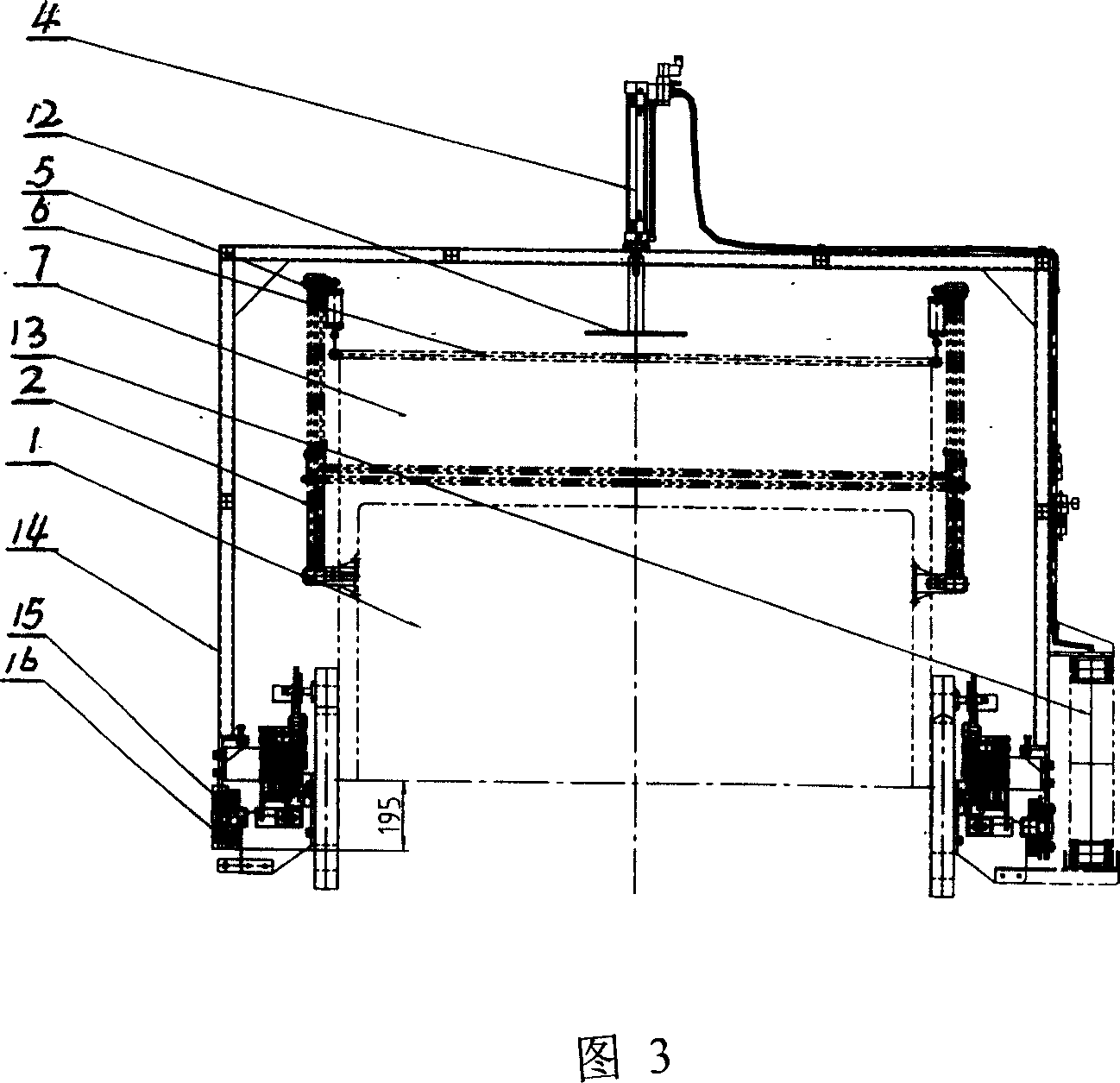

Embodiment 1

[0011] Embodiment 1: Refer to Figures 1-3. The filter cloth varicose rapping mechanism of the filter press, the multi-group varicose rods 2 are processed and manufactured according to the prior art with reference to the accompanying drawings, and the lower ends of the multi-group varicose rods 2 are hinged to each other and are hinged with the two sides of the filter plate 1 to form a horizontal filter plate push-pull mechanism (similar to Folding sliding door upper structure), the upper ends of the varicose rods located on both sides of each group of filter plates 1 are connected with the filter cloth hanger rod assembly 6 through the varicose spring 5, and the filter cloth hanger rod assembly 6 is suspended by two pieces of cloth hanging seat 9 , two filter cloth rods 10, the two bottom corners of the hanging cloth hanging seat 9 are provided with filter cloth rod installation holes, the top corners are provided with varicose spring connection holes, and the two bottom corner...

Embodiment 2

[0012] Embodiment 2: On the basis of embodiment 1, the rapping method of the filter cloth varicose rapping mechanism of the filter press, the pulling plate mechanism pulls the varicose rapping mechanism, and the filter plate in the varicose rapping mechanism is driven by the varicose rapping rod, After the filter plate and the filter plate are gradually opened, the rapping mechanism located on it directly hits the filter cloth hanger on the top of the varicose rod. Drive the filter cloth to vibrate strongly, forcing the filter cake on the filter cloth to fall. After the filter cake falls, the filter cloth and filter cloth rod are reset under the action of the varicose spring, and the filter cloth is reset with the filter cloth rod. The filter cake in the cloth buckling rapping mechanism is rapped down quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com