An oil-cooled motor for preventing electrical corrosion of bearings

An electrical corrosion and bearing technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of electrical corrosion of bearings, affect the reliability of the motor, the noise performance of the motor, and affect the service life of the motor, and achieve the prevention of electrical corrosion and a simple structure. , Improve the effect of motor life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

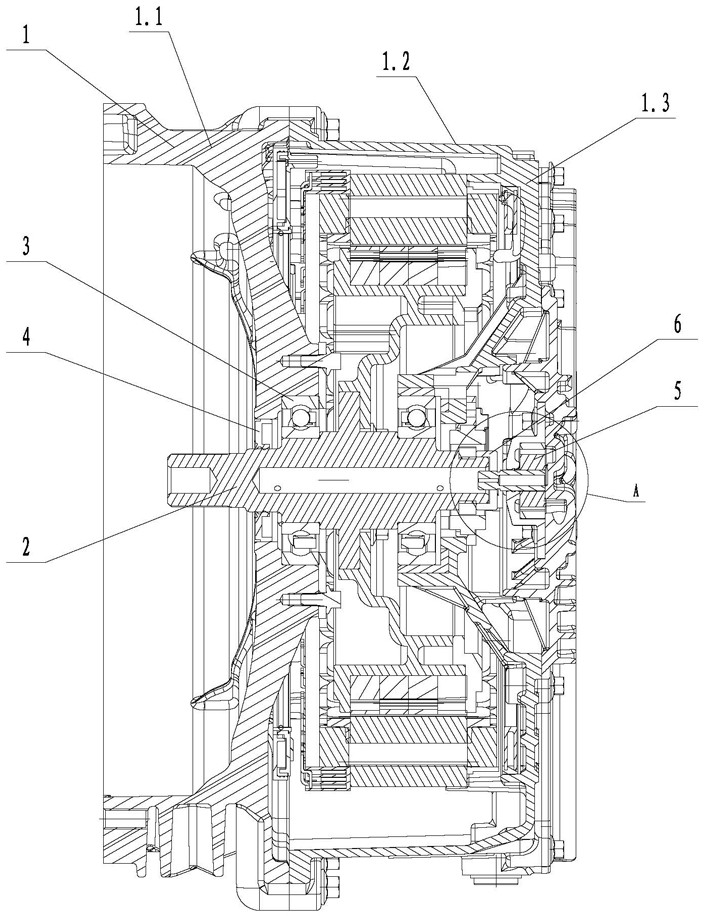

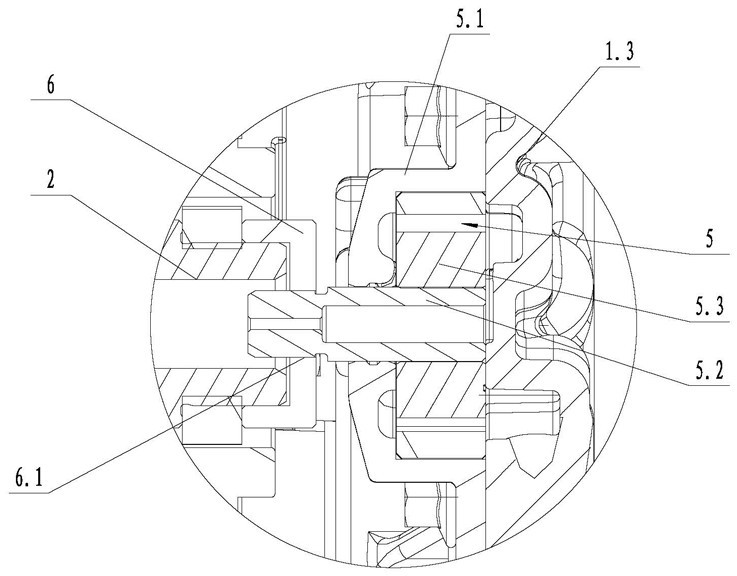

[0024] like figure 1 As shown, an oil-cooled motor for preventing electrical corrosion of bearings includes a motor housing 1, a motor shaft 2, a bearing 3, a conductive oil seal 4 and an oil pump assembly 5, the motor housing 1 is grounded through a conductor, and the motor The housing 1 includes a motor front housing 1.1, a motor rear housing 1.2 and a motor rear end cover 1.3, and the motor front housing 1.1, the motor rear housing 1.2 and the motor rear end cover 1.3 are electrically connected.

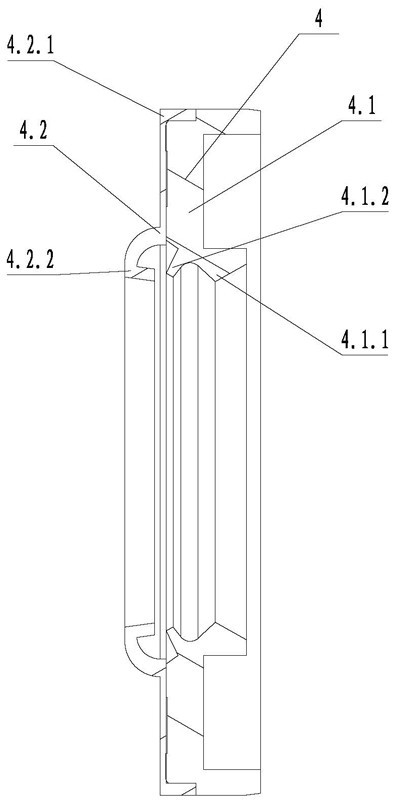

[0025] The motor shaft 2 is rotationally connected with the motor housing 1 through two bearings 3, the conductive oil seal 4 and the oil pump assembly 5 are respectively arranged at both ends of the motor shaft 2, the conductive oil seal 4 is arranged outside the bearing 3, and the conductive oil seal 4 is set On the motor shaft 2 , one end of the motor shaft 2 is electrically connected to the motor housing 1 through the conductive oil seal 4 , and the other end of the motor shaf...

Embodiment 2

[0030] like Figure 4 As shown, on the basis of Example 1, the wear resistance of the material of the motor shaft 2 is greater than that of the conductive member 4.2, and the end surface of the contact part 4.2. Installation groove 4.2.3, there is an oil scraper 7 inside the installation groove 4.2.3, one end of the oil scraper 7 is fixed to the bottom surface of the installation groove 4.2.3, the other end of the oil scraper 7 is in contact with the motor shaft 2, and the oil scraper The sheet 7 and the contact portion 4.2.2 are on the same circumferential contour of the motor shaft 2 . The oil scraper 7 is arranged obliquely relative to the axis of the motor shaft 2 . The structure can scrape oil at the contact position between the motor shaft 2 and the contact part 4.2.2 through the oil scraper 7, so as to prevent the leaked oil from affecting the conduction of the contact part 4.2.2. The oil scraper 7 is arranged obliquely relative to the axis of the motor shaft 2 to scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com