Confined conjugated microporous polymer composite membrane as well as preparation method and application thereof

A conjugated microporous and polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low separation accuracy, low solvent flux, insufficient swelling resistance, etc., and achieve enhanced penetration Effects of flux, avoidance of brittleness, good chemical stability and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of a confinement conjugated microporous polymer composite membrane of the present embodiment, the specific steps are as follows:

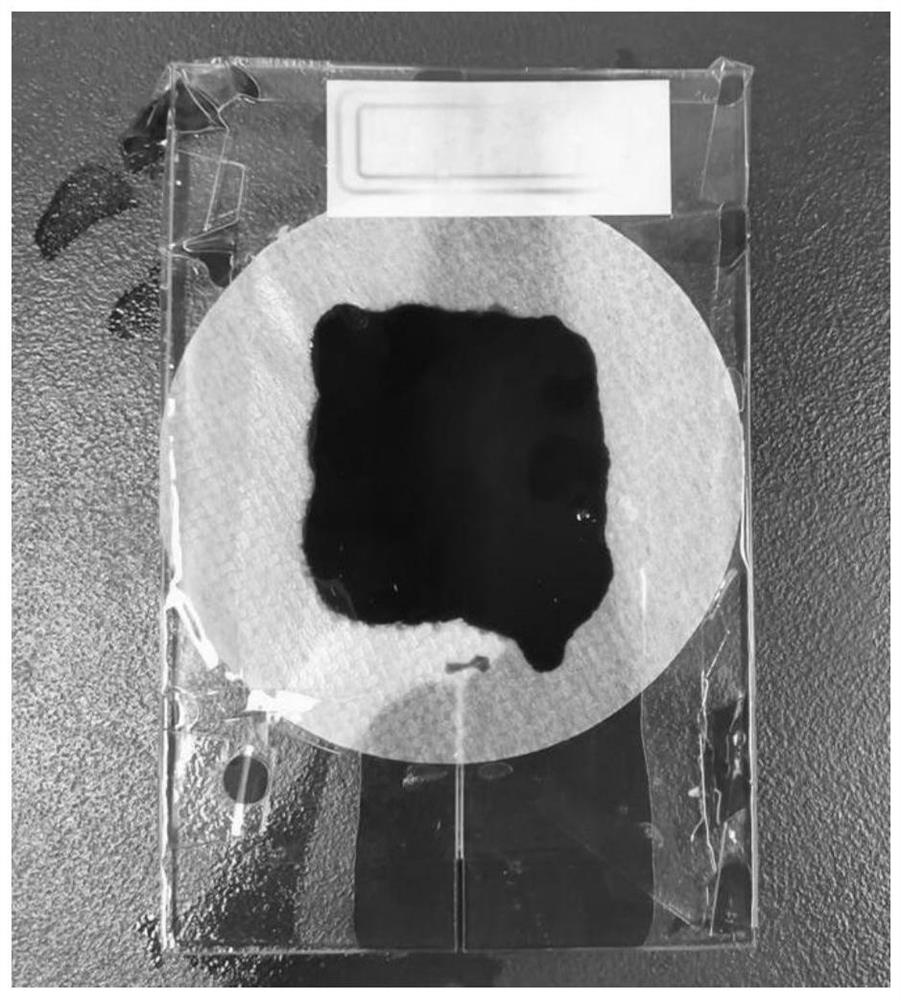

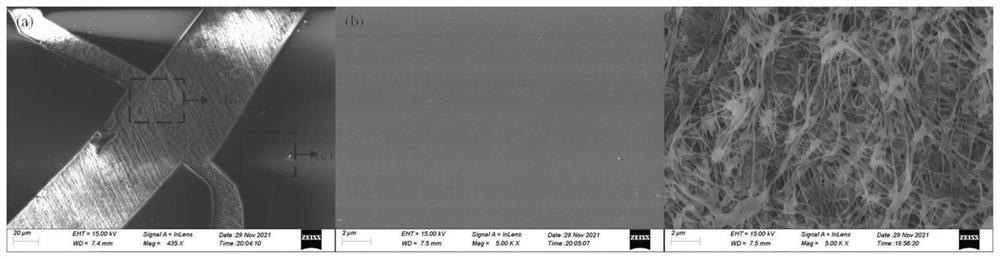

[0050] First, 16.2 mg of 1,4-diacetophenone reaction monomer (CAS No.: 1009-61-6, FW: 162.19) was weighed and dissolved in 2 mL of toluene solution. After it was completely dissolved, 0.5 mL of trifluoro trifluoride was added quickly. Methanesulfonic acid, mix well, transfer the obtained mixed reaction solution to a muffle furnace, heat it to 100 ° C for 26 hours, and prepolymerize to form a prepolymerized solution with a certain viscosity; then drop the prepolymerized solution with a certain viscosity while hot. On the polymer base film (PTFE), the prepolymer solution is evenly distributed on the surface of the base film by shaking with a shaker; after the prepolymer solution is formed, it is placed in an oven at 100 ° C for thermal curing for 24 hours. Secondary Polymerization reaction; after the conjugated microporo...

Embodiment 2

[0062] The preparation method of a confinement conjugated microporous polymer composite membrane of the present embodiment, the specific steps are as follows:

[0063] First, 20.4 mg of 1,3,5-triacetophenone reaction monomer (CAS No.: 779-90-8, FW: 204.22) was weighed and dissolved in 2 mL of N,N-dimethylacetamide solution. After complete dissolution, 1 mL of trifluoromethanesulfonic acid was quickly added and mixed well; the obtained mixed reaction solution was transferred to a muffle furnace, heated to 100 °C for 20 hours, and a prepolymerization reaction occurred to form a prepolymerized solution with a certain viscosity; The viscous prepolymer droplets are coated on the polymer base film (PVDF), and the prepolymer solution is evenly distributed on the surface of the base film by shaking with a shaker; after the prepolymer solution is formed, it is placed in an oven at 100 °C. After thermal curing for 36h, a secondary polymerization reaction occurred; after the conjugated m...

Embodiment 3

[0067] The preparation method of a confinement conjugated microporous polymer composite membrane of the present embodiment, the specific steps are as follows:

[0068] First, 8.1 mg of 1,4-diacetophenone and 10.2 mg of 1,3,5-triacetophenone were weighed and dissolved in 2 mL of N,N-dimethylacetamide solution. After they were completely dissolved, 3 mL was added quickly. The obtained mixed reaction solution was transferred to an oven, heated to 100°C for 30 hours, and prepolymerized to form a prepolymerized solution with a certain viscosity; then the prepolymerized solution with viscosity was applied to the polymer On the basement film (PAN), and shake the prepolymer solution evenly on the surface of the basement membrane by shaking it; after the prepolymerization solution is formed, it is placed in an oven at 120 ° C for thermal curing for 48h, and a secondary polymerization reaction occurs; After the membrane is formed, the membrane is sequentially washed three times in an aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com