Deposited manganese sheet automatic detachment machine on electrolytic manganese metal negative plate

An electrolytic manganese metal, automatic detachment technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of easy breakage of the hammer rod, large error, complex structure, etc., and achieve the effect of flexible tapping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

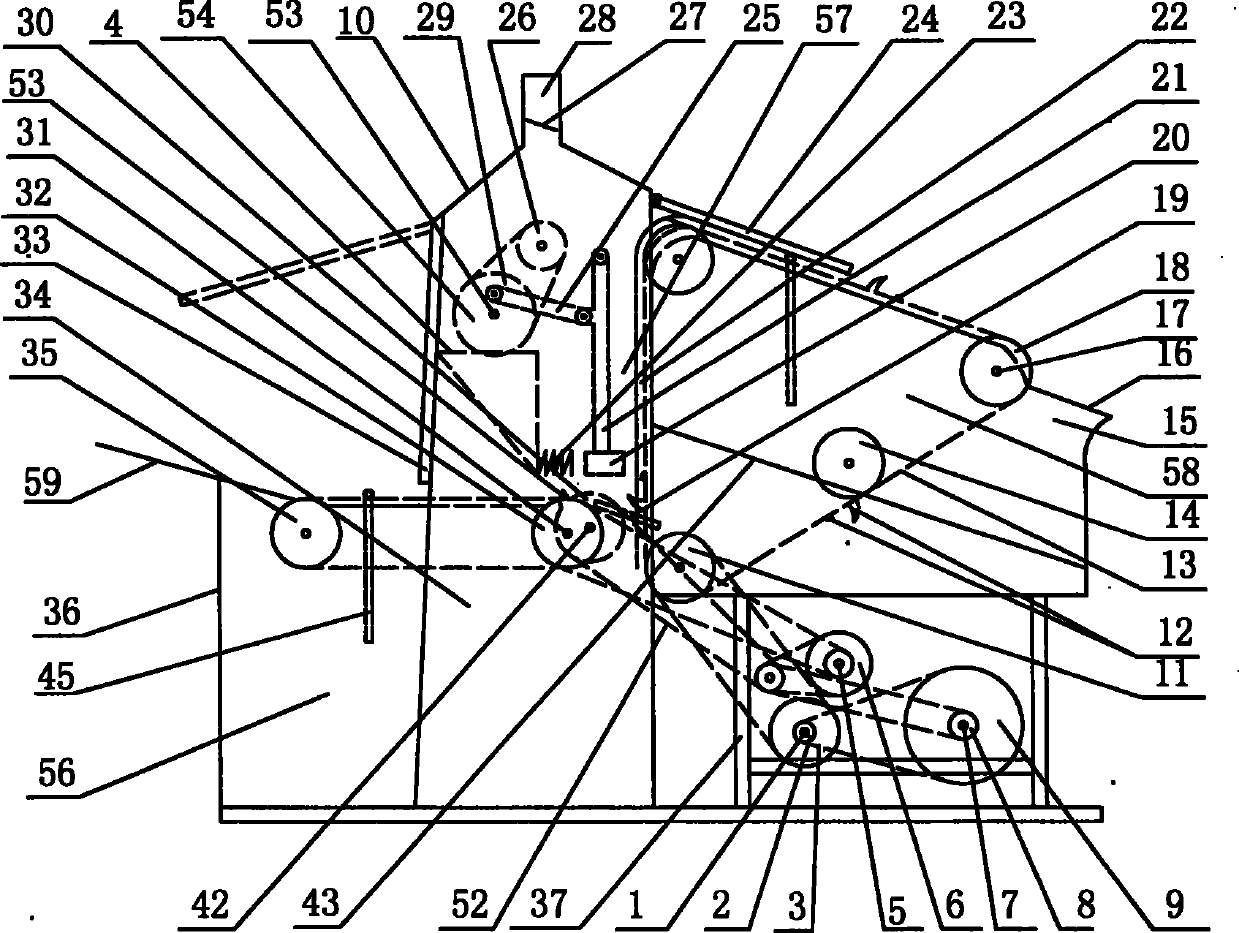

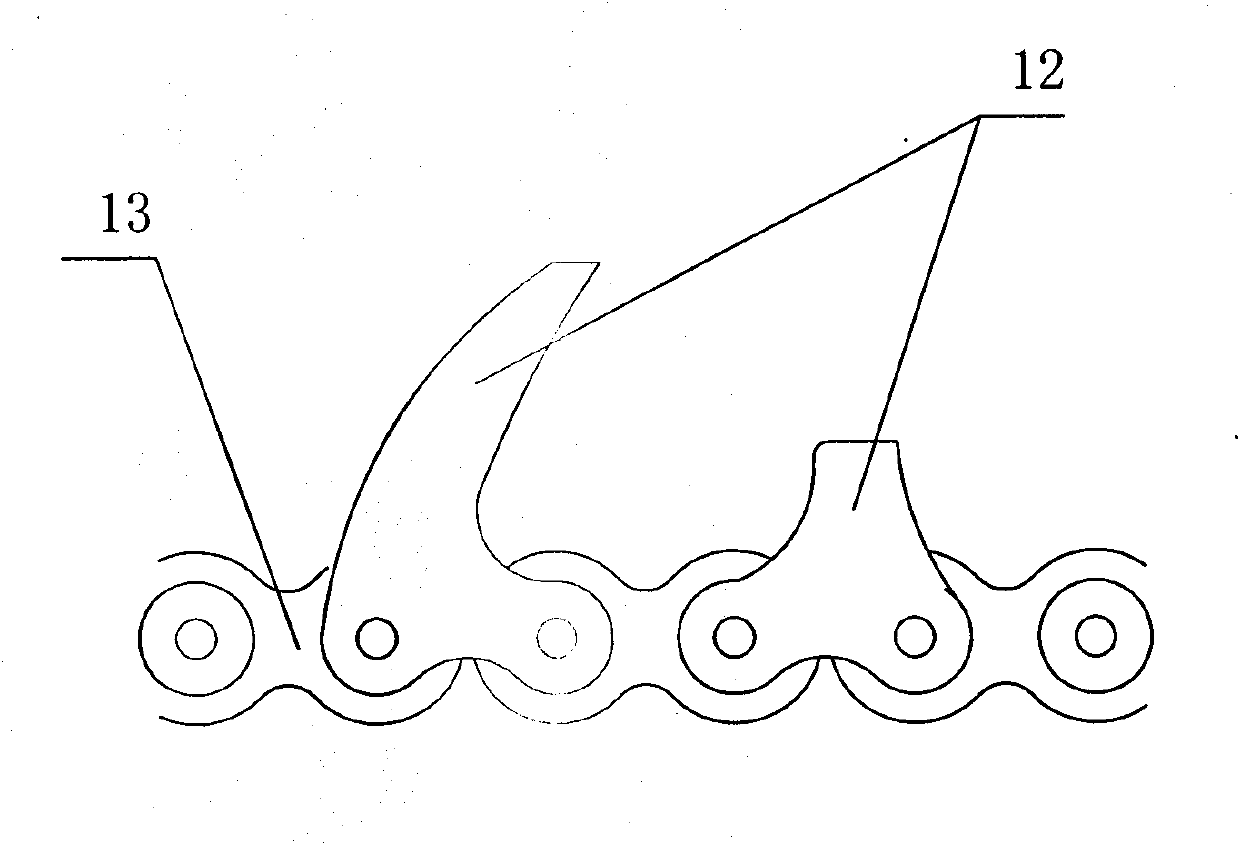

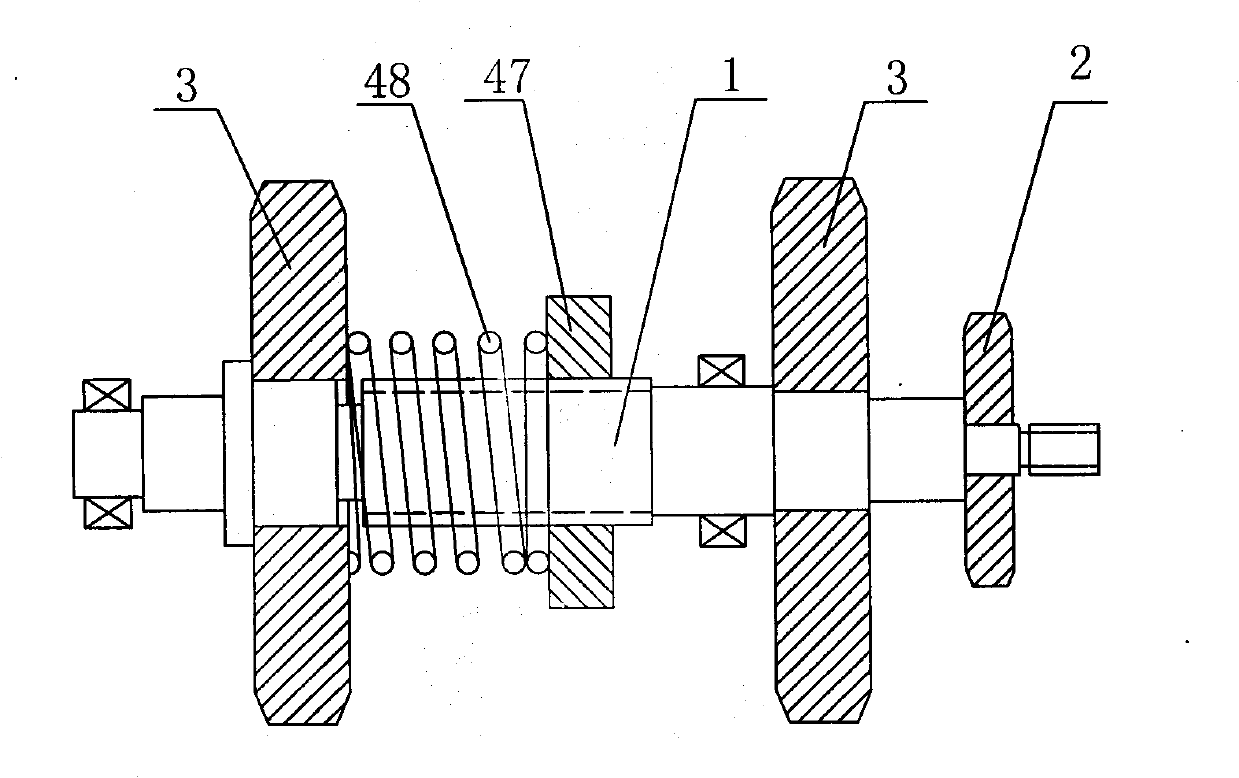

[0027] Such as Figure 1-Figure 3 As shown, the front portion of the main frame 37 is provided with a plate-feeding support 36 , the top is provided with a plate-feeding support 16 , and the top of the plate-feeding support 36 is provided with a knocking plate support 4 . Both sides of the board-feeding support 36 are symmetrically provided with a board-feeding vertical plate 40, and a plate-feeding sprocket shaft 31 is installed on the plate-feeding vertical plate 40, and a plate-feeding driving sprocket 32, a plate-feeding driven sprocket 35 and a plate-feeding plate are installed The chain 39 constitutes a plate-feeding mechanism, which is used to continuously transport the pole plate 45 to the plate-separating wheel 30 , and a plate-feeding channel 56 is formed between the two plate-feeding vertical plates 40 . The both sides of the lose plate support 16 are symmetrically provided with the lose plate vertical plate 15, the lose plate vertical plate 15 is equipped with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com