Sealing system of mechanical rapping apparatus

A technology of sealing system and rapper, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., to achieve the effects of improving reliability, increasing life, and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with examples.

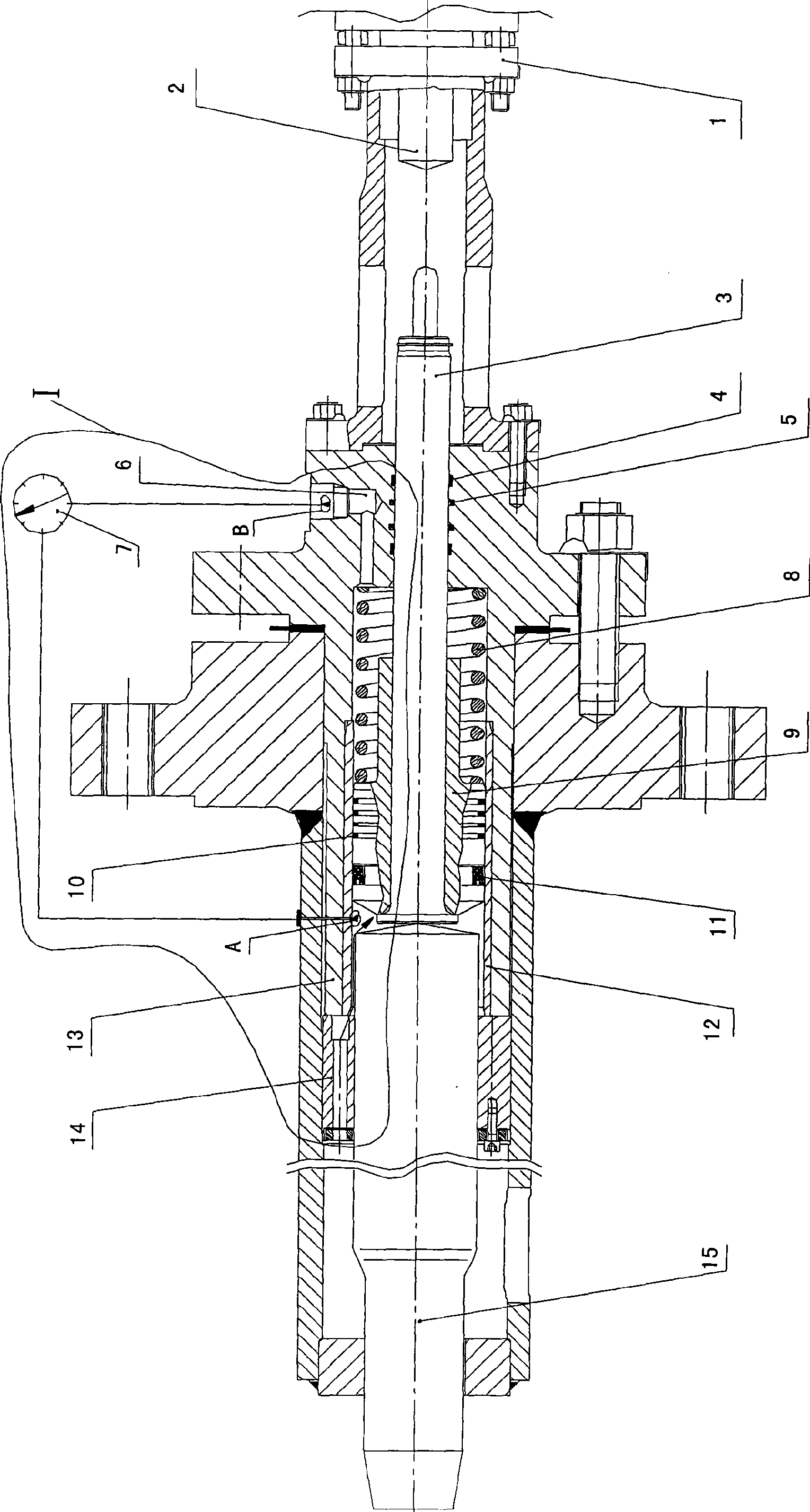

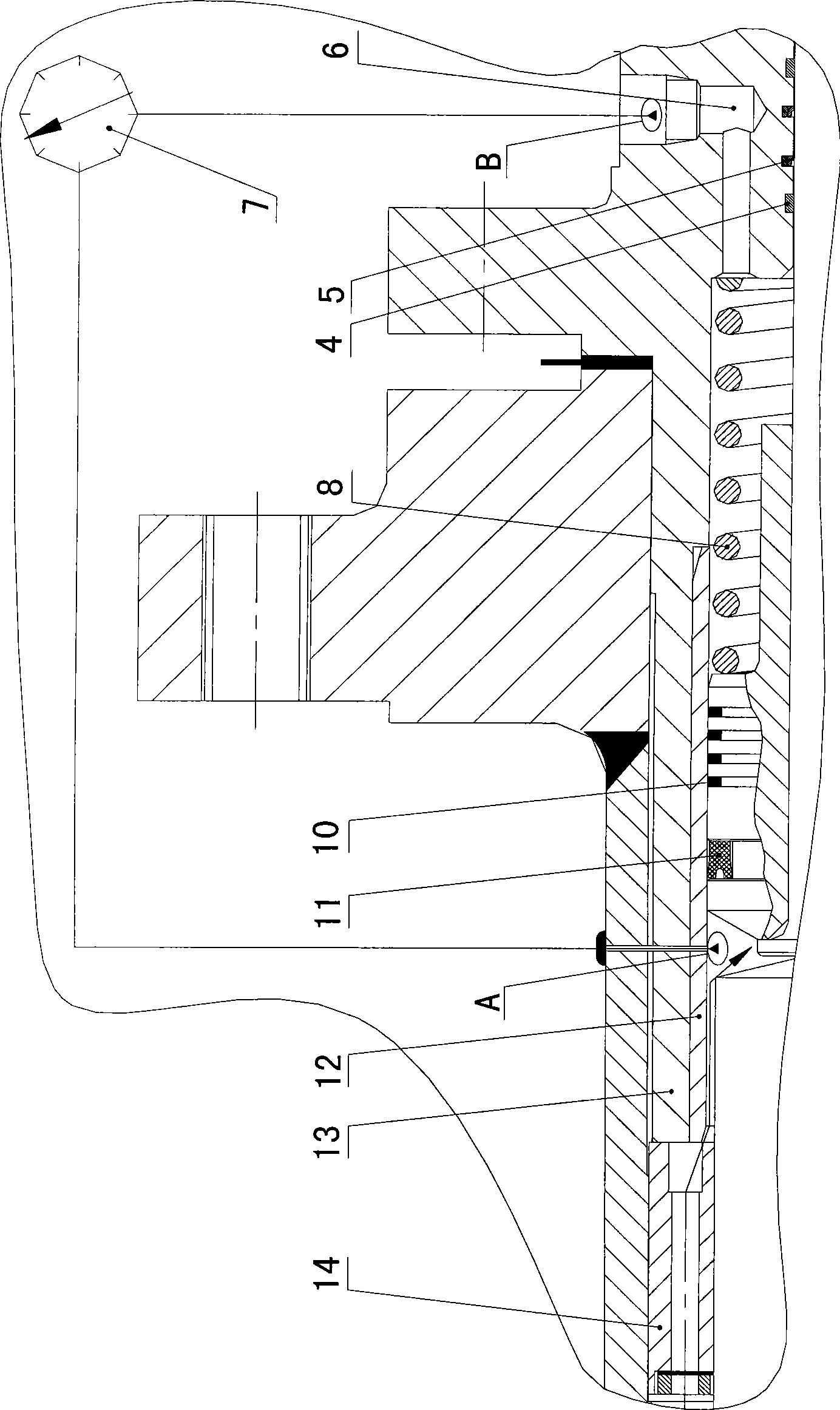

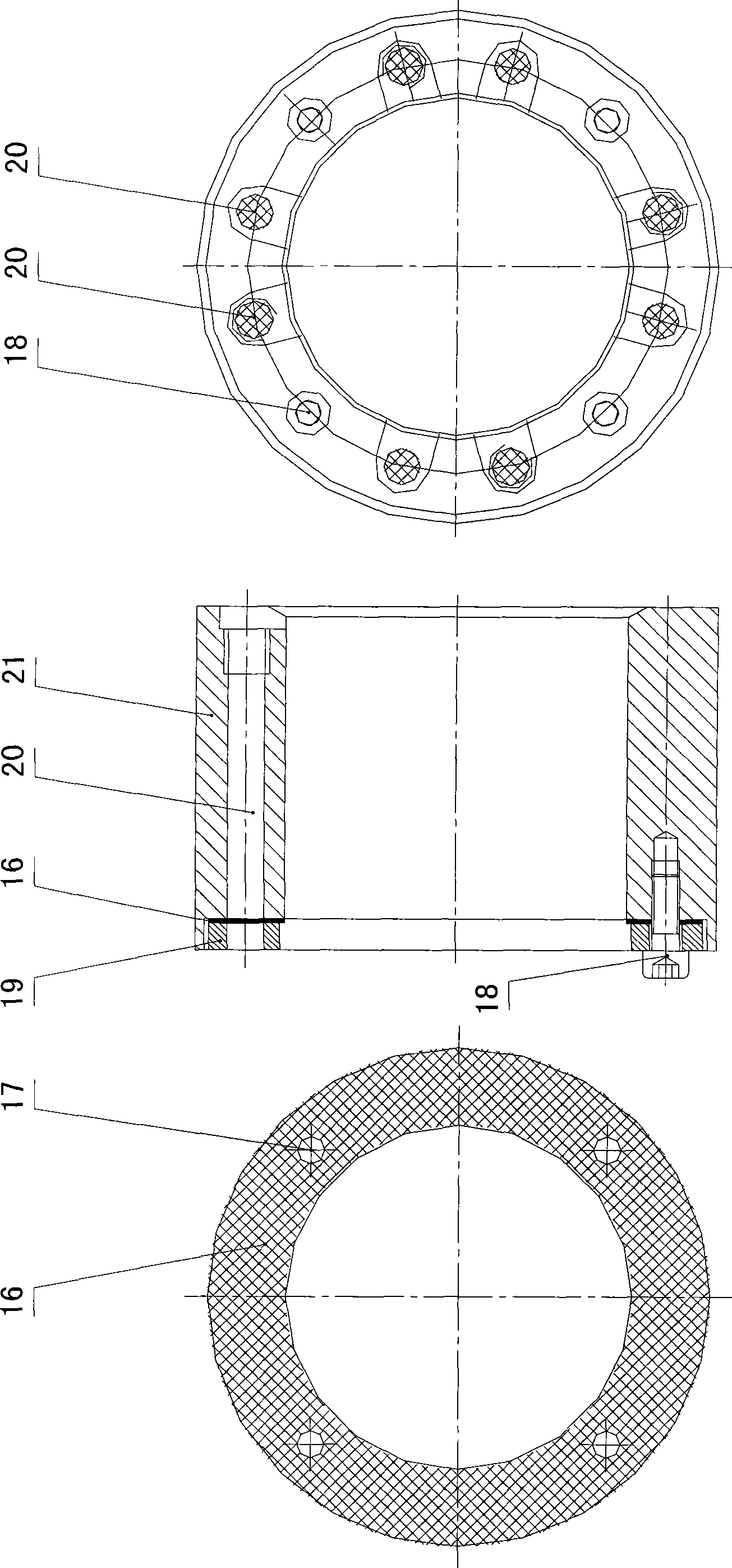

[0024] exist figure 1 , 2 Among them, the sealing system of the mechanical rapper is composed of a filter 14, a Y-shaped sealing ring 11, a piston ring 10, an air inlet 6, a lining ring 5, a guide ring 4, and a gas leakage alarm device 7; The transmission rod 2 of the cylinder is connected to the piston rod 3, and the piston rod 3 is connected to the impact rod 15. The filter 14 is installed on the impact rod 15 in front of the piston guide tube 13, and the dust gas in the gasification equipment is After the dust is filtered out by the filter 14, it enters the gap between the piston rod 3 and the piston 9, the piston 9 and the piston sleeve 12 inside the piston sleeve 12 ( figure 1 , the direction of the arrow inside the filter in 2), to ensure that the pressure at the contact position of the impact rod 15 and the piston rod 3 is the same as the pressure in the vaporization eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com