Novel rubber abrasion test machine

A wear test and wear machine technology, applied in the direction of testing wear resistance, instruments, measuring devices, etc., can solve the problems of cumbersome experimental process, insufficient simulation of rubber heat generation, affecting rubber samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

[0035] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings.

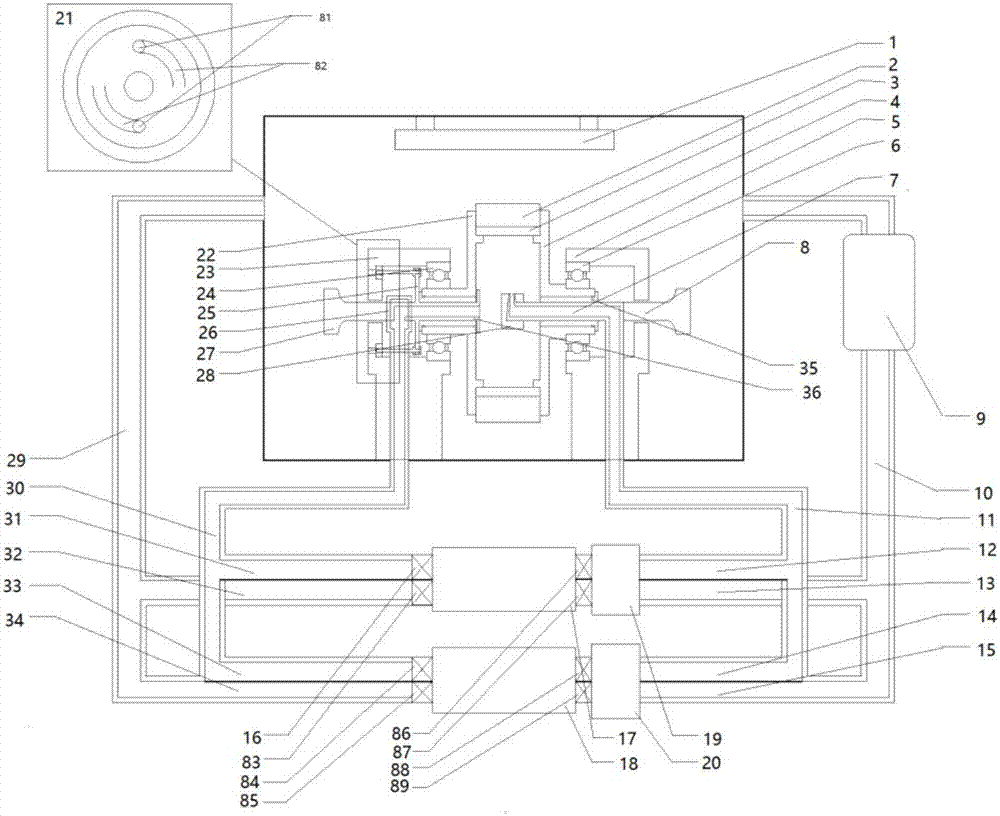

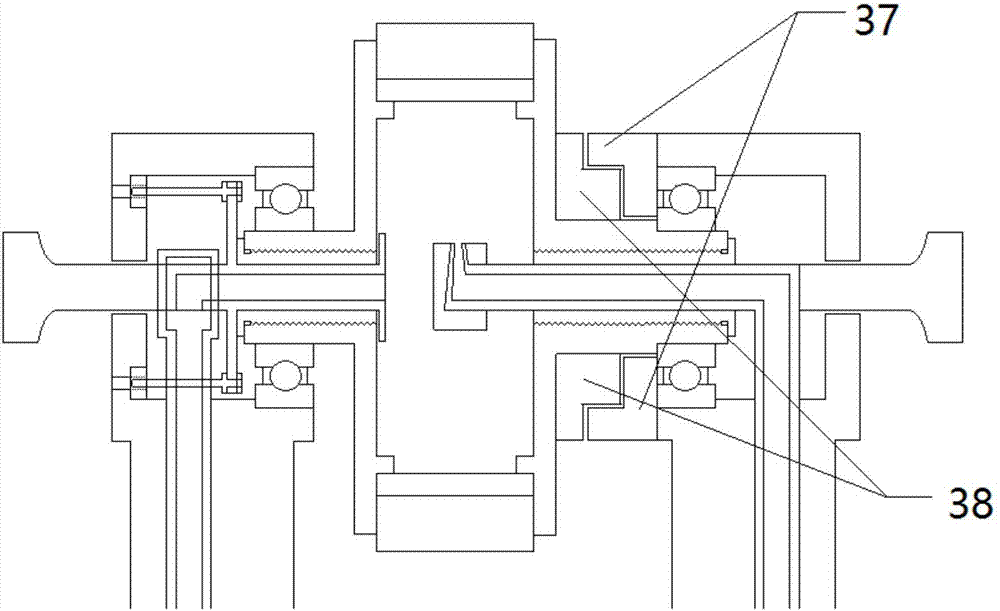

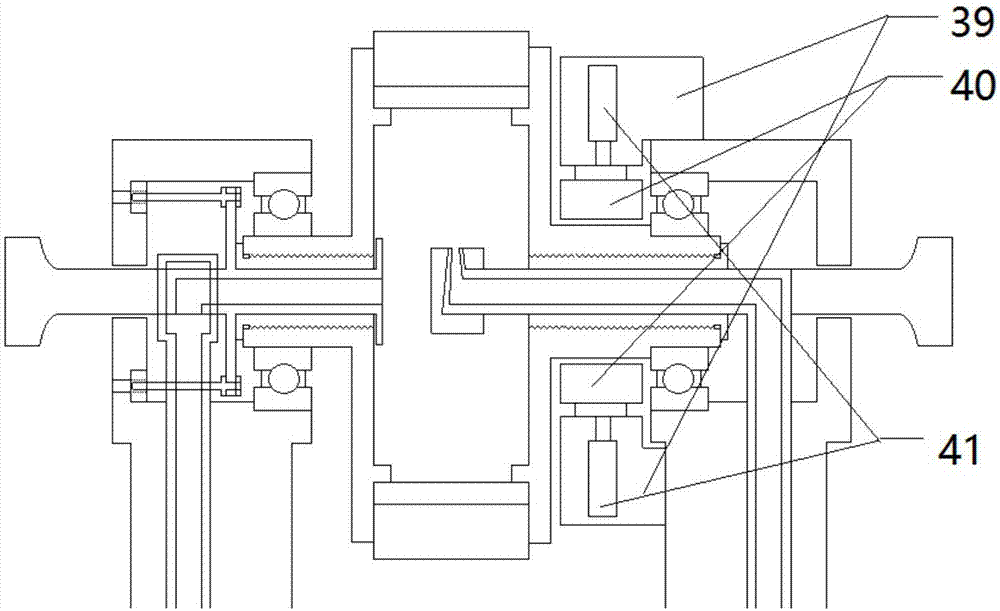

[0036] In the technical solution of the invention, the new type of rubber abrasion machine adopts a vertical structure, and the main parts include: the machine base, the chassis, the heat transfer hub of the fixed part of the rubber wheel sample (2), and the sand of the friction part of the rubber wheel sample (2). The belt (56) and pulley and friction anvil (52), the machine shaft and machine system of the rubber wheel sample experimental state control device, the aging test system, the drying device inside the cabinet of the rubber wheel sample temperature control part, and the temperature control system. Formation, braking device, control panel, rapping device, shock absorbing device, wear machine overall control part.

[0037] The chassis is made of glass, hard acrylic or other transparent materials with suff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com