Installation and construction method for high-altitude pipeline in circular-section tunnel

A technology of pipeline installation and construction method, which is applied in the direction of overhead line/cable equipment, cable laying equipment, etc., to achieve the effects of good economy, improved stability and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

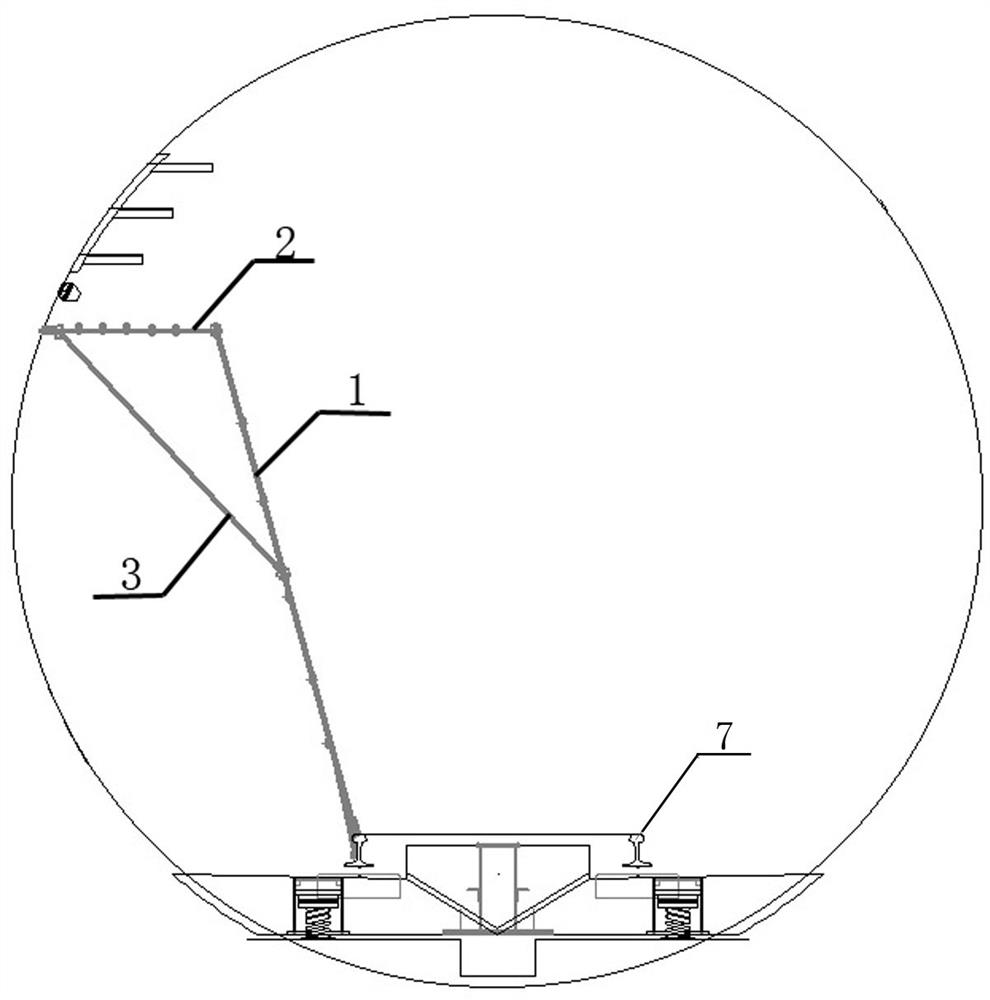

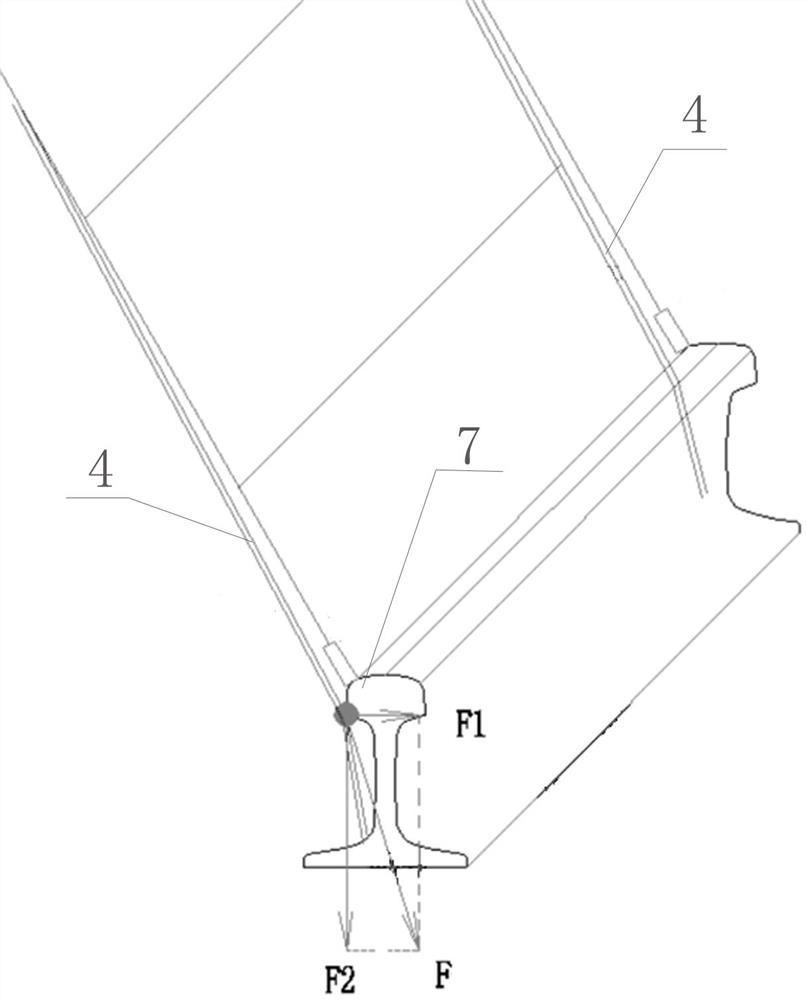

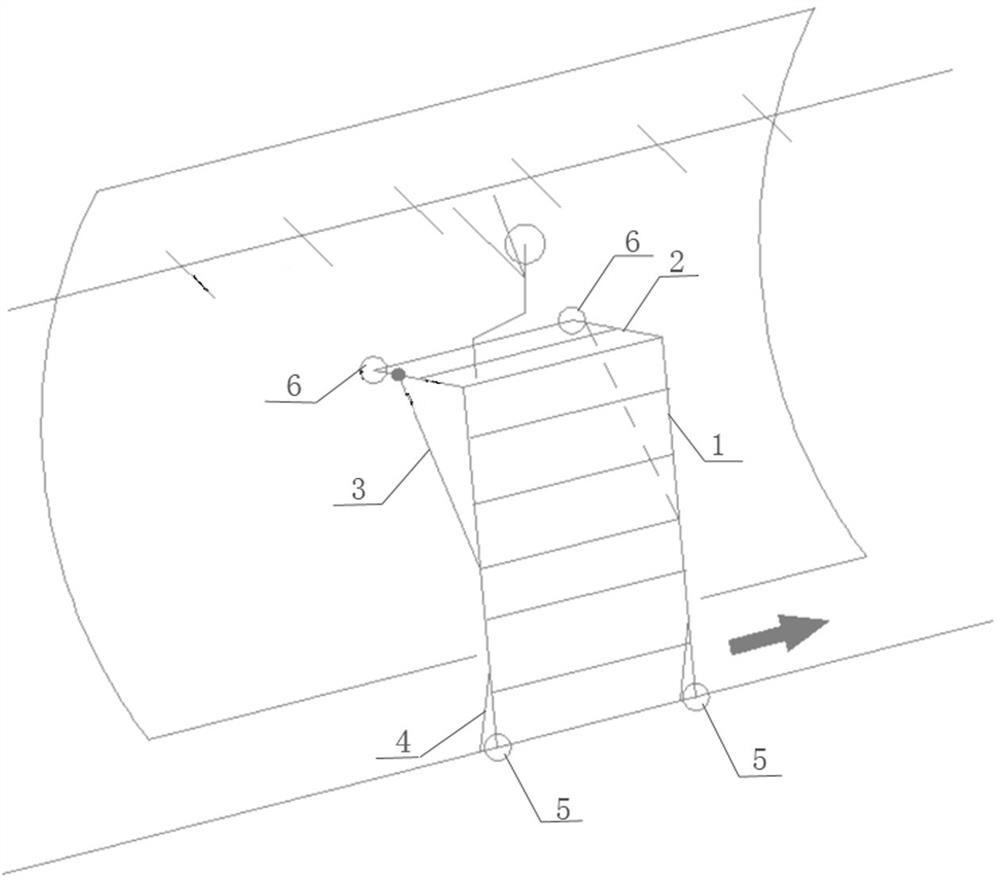

[0019] The construction method for the installation of high-altitude pipelines in a circular-section tunnel includes the following steps: construction preparation → production of rail-type folding tooling → prefabrication processing → bracket installation → pipeline installation → wire laying → lighting installation → cable laying → system debugging.

[0020] Construction preparation

[0021] Construction preparation mainly includes personnel preparation, mechanical equipment preparation, material preparation, construction method preparation, measurement and lay-out.

[0022] (1) Personnel preparation mainly includes: technical personnel preparation and construction personnel preparation.

[0023] Prepared by technical personnel, the project department divides the construction sections according to the construction content and construction volume, and the construction personnel of each section are determined by the workload. First, the construction majors are divided accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com