Bidirectional hot-pressing high-temperature oscillation sintering furnace and working method thereof

A working method and technology of sintering furnace, which are applied in the field of sintering furnace to achieve the effects of improving product performance, high pressure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

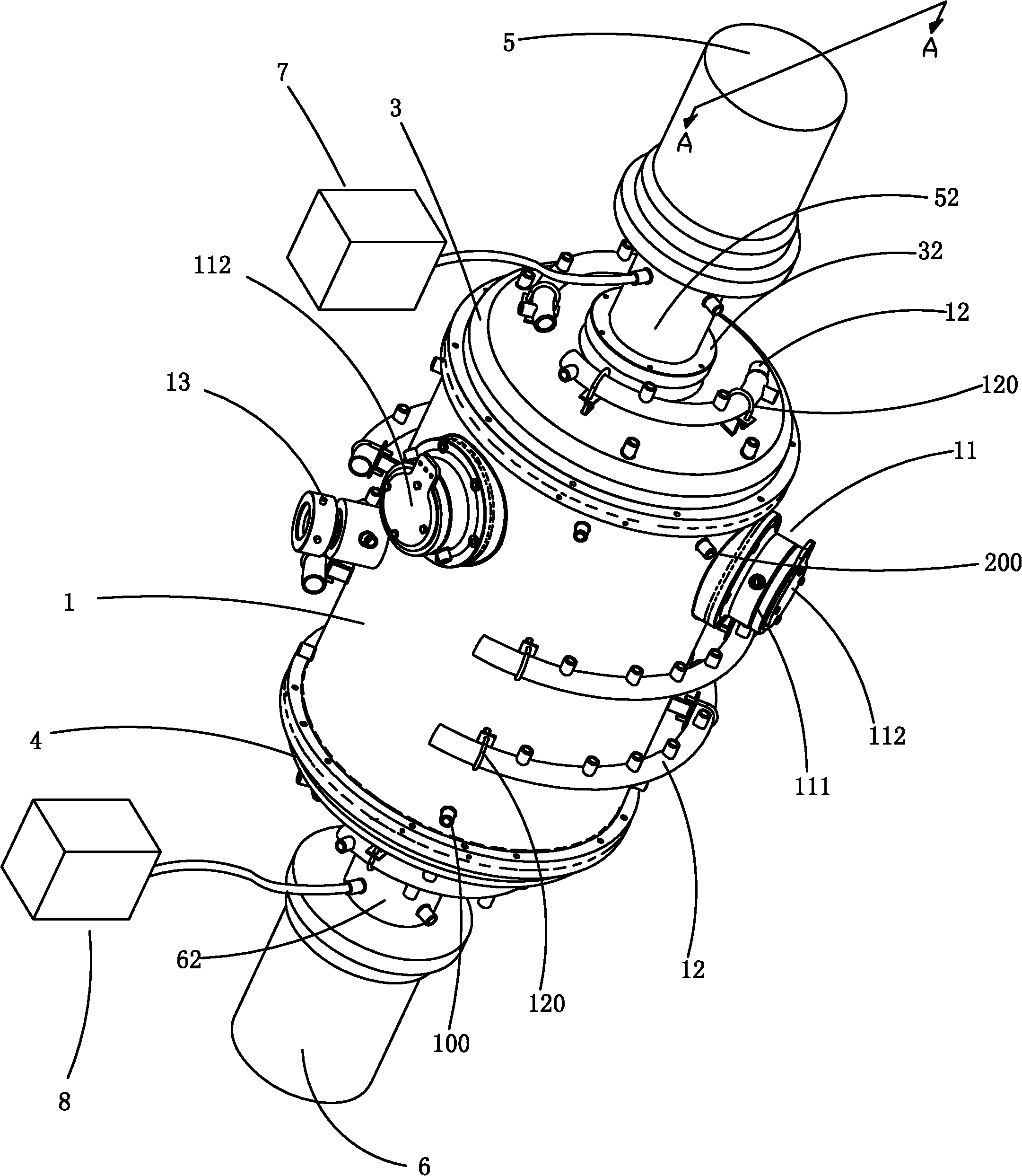

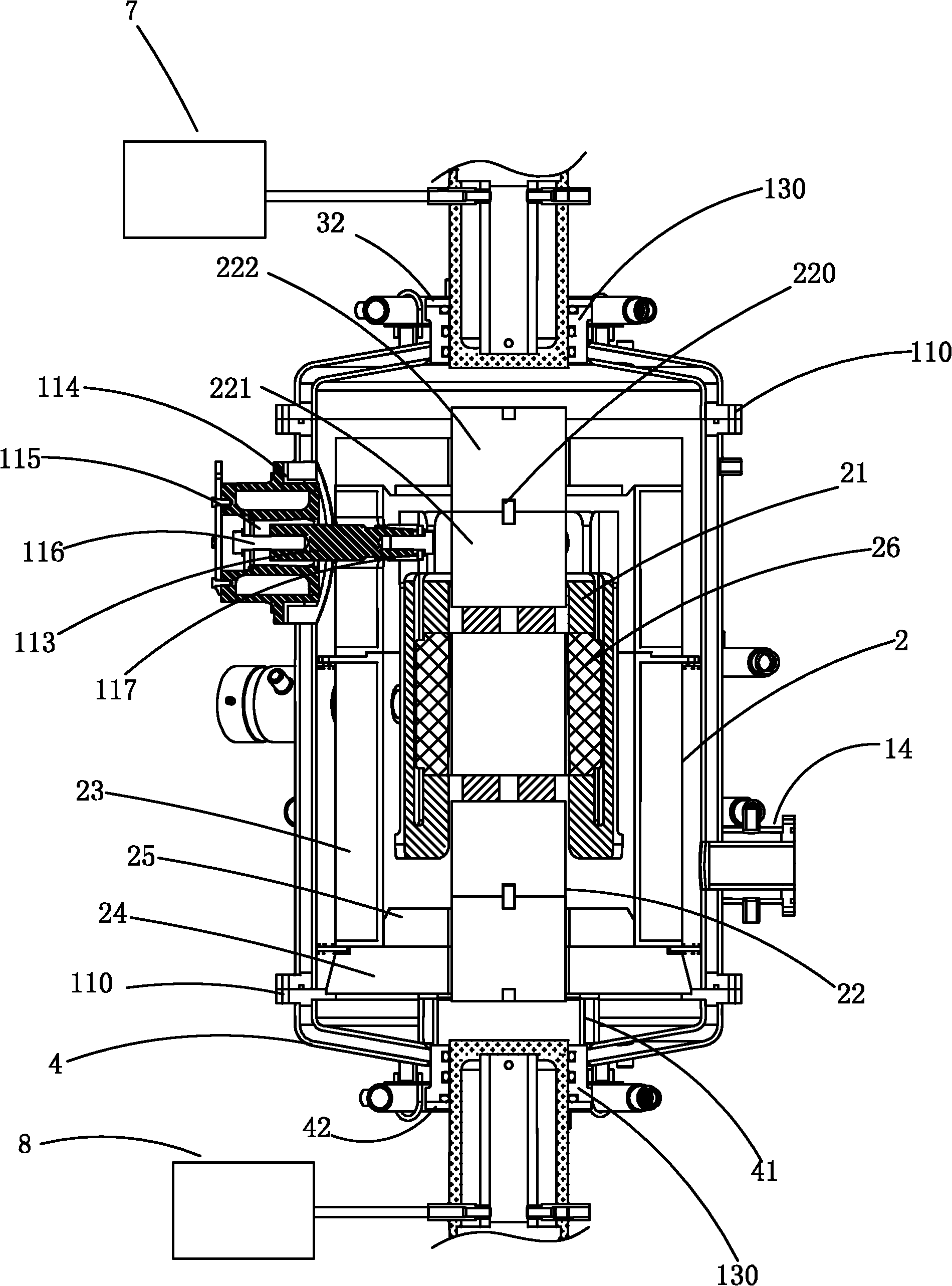

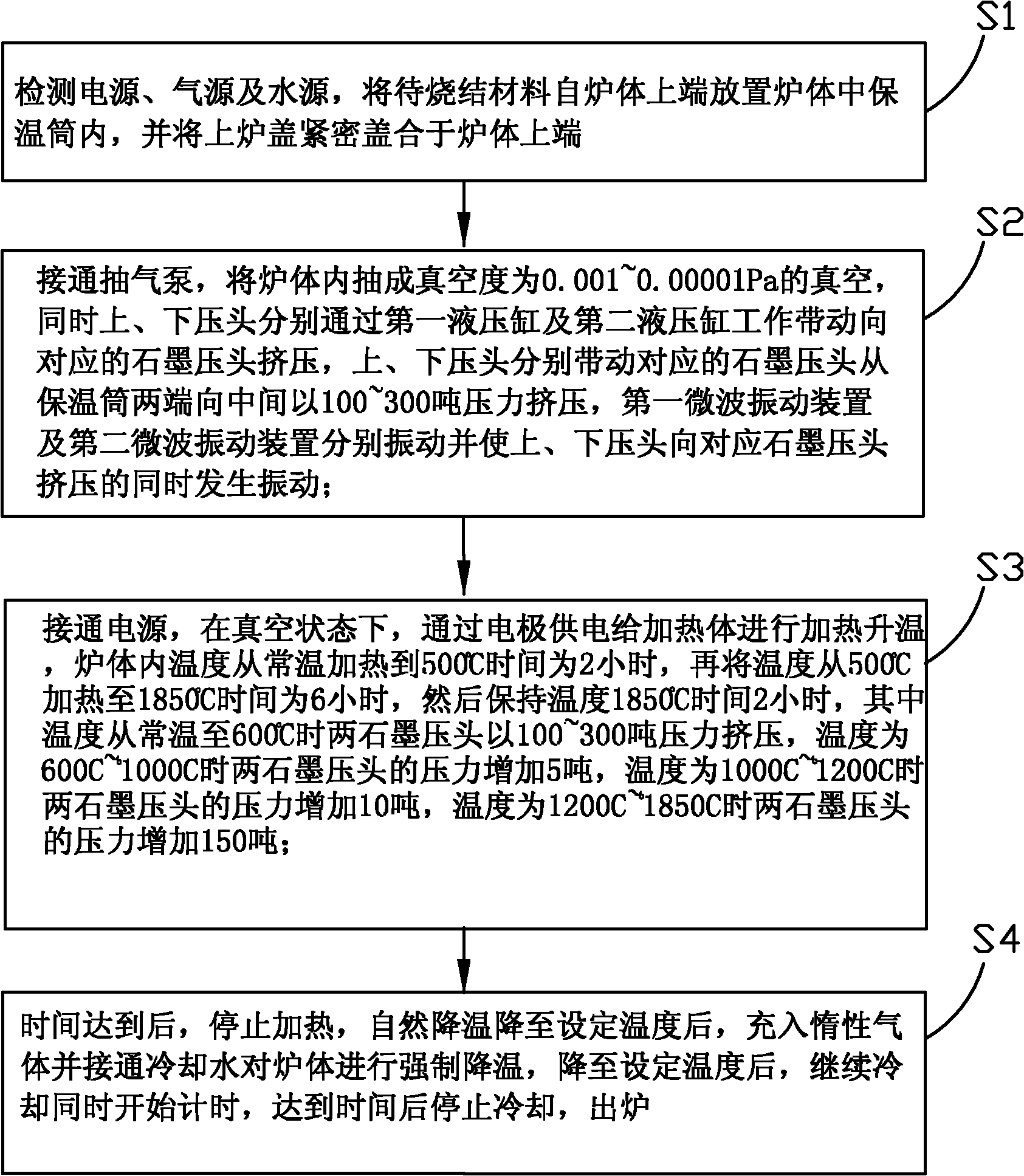

[0032] Such as Figure 1-2 As shown, the two-way hot-pressed high-temperature oscillating sintering furnace of the present invention includes: a first hydraulic cylinder 5 with a first movable rod, a second hydraulic cylinder 6 with a second movable rod, a furnace body 1, and a furnace body 1 The inner heat preservation tube 2, the upper furnace cover 3 and the lower furnace cover 4 which are respectively sealed and covered by flanges on the upper and lower ends of the furnace body 1, are integrally extended by the first movable rod of the first hydraulic cylinder 5 and installed on the upper furnace cover. 3, the lower pressing head 62 integrally extended by the second movable rod of the second hydraulic cylinder 6 and installed on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com