Silo wall rapping air hammer

A technology of air hammer and silo wall, which is used in the field of devices for clearing hopper blockages and making material conveying unobstructed, can solve the problems of safety, large ash content, clogging in silo or cone hopper and other problems, so as to achieve high vibrating force. , the effect of strong dredging ability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

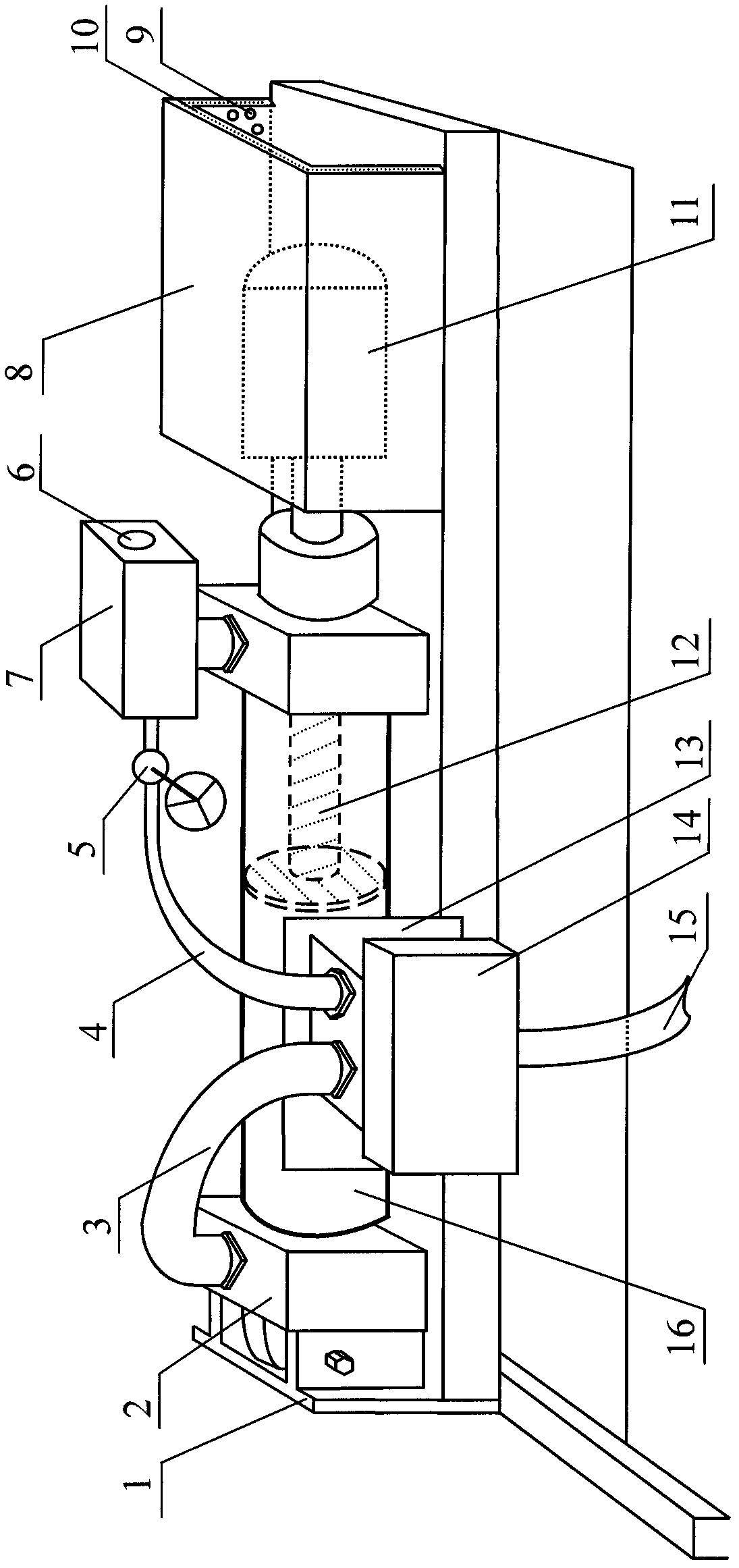

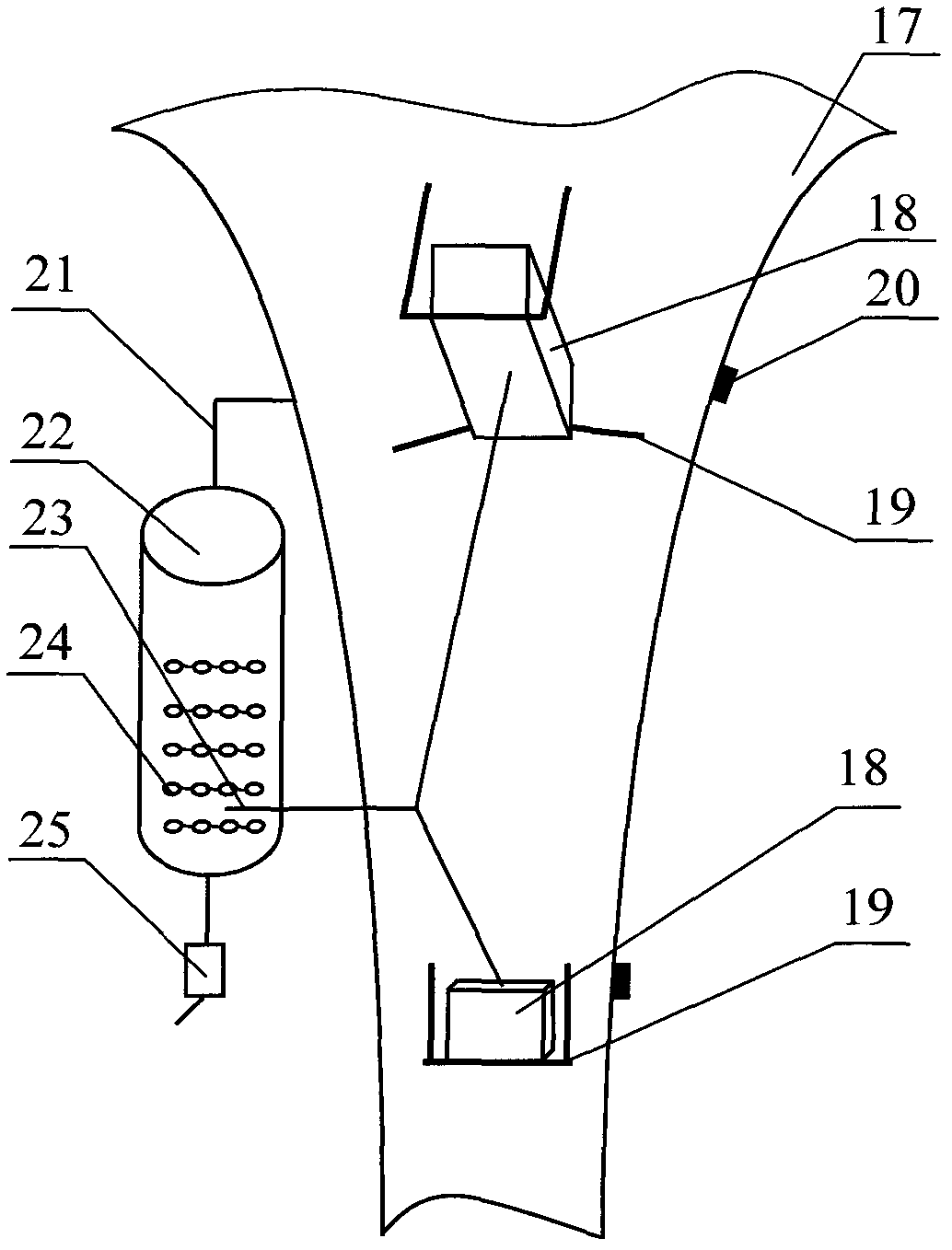

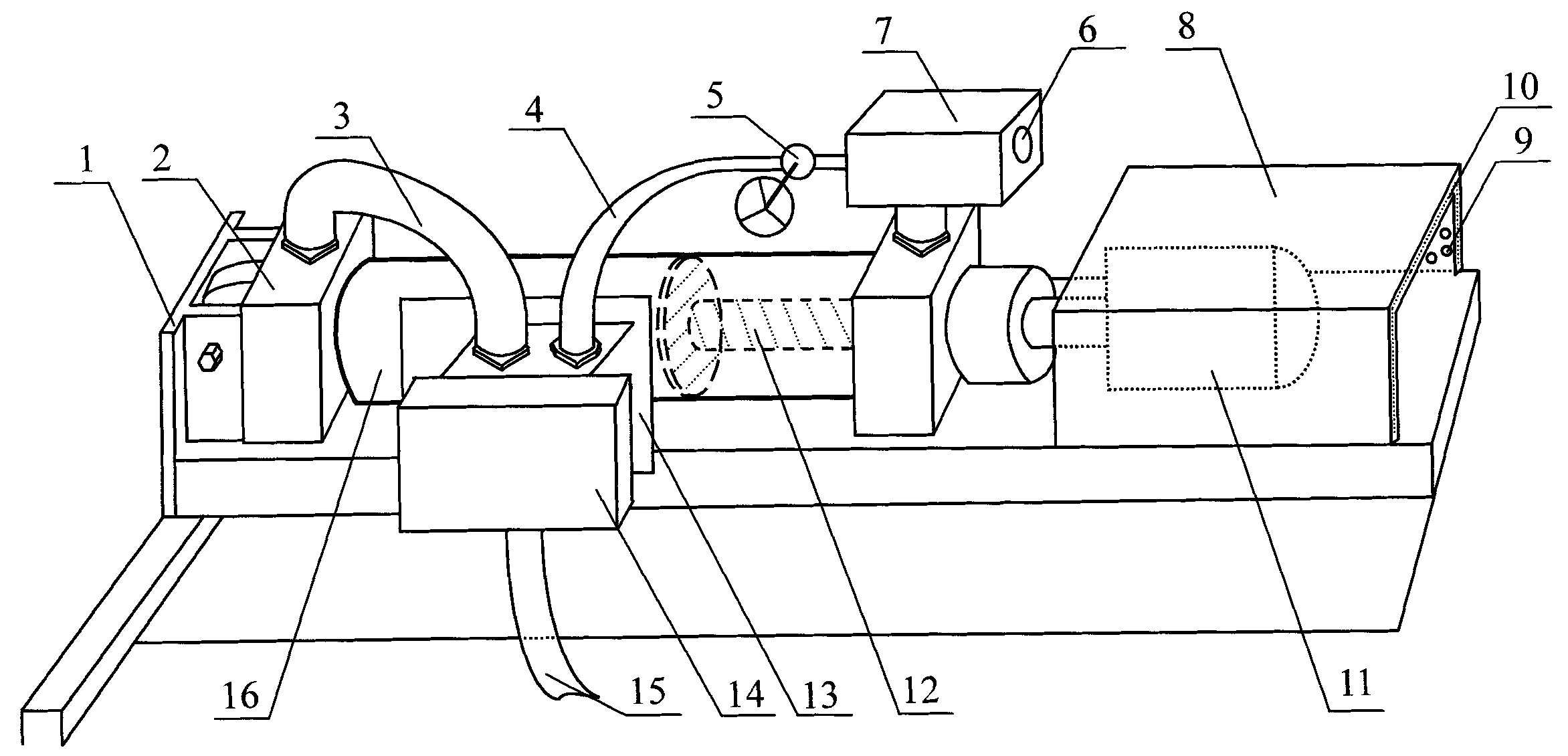

[0019] like figure 1 As shown, the present invention includes an electromagnetic reversing valve 14, a cylinder 16, a hammer 11, a quick exhaust valve 7 and the like.

[0020] The cylinder 16 is fixed on the base 1 through the fixed seat 2, and the piston rod 12 is connected to the hammerhead 11 inside. The electromagnetic reversing valve 14 is connected to the air outlet pipeline 23 of the gas storage tank 22 through the intake pipeline 15, and is respectively connected to the two ends of the cylinder 16 through the front air pipe 3, the rear air pipe 4 and the quick exhaust valve 7, and the rear air pipe 4 and the quick exhaust valve. A regulating valve 5 is arranged between the air valves 7 . Adjusting the valve 5 can adjust the air intake, and then adjust the vibration amount when the tuplet 11 returns. That is, the valve 5 can be adjusted to open wide and open small to control the gas volume entering the cylinder 16 from the rear air pipe 4, so that the hammer head 11 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com