Turbulence forming appliance and heat exchanger and water heater using same

A technology for heat exchangers and water heaters, applied in heat exchange equipment, fluid heaters, fluid mixers, etc., which can solve problems such as gap corrosion of heat transfer tubes 4, difficulty in fluid circulation, and large flow path resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The mode for carrying out the present invention will be described in detail with reference to the drawings.

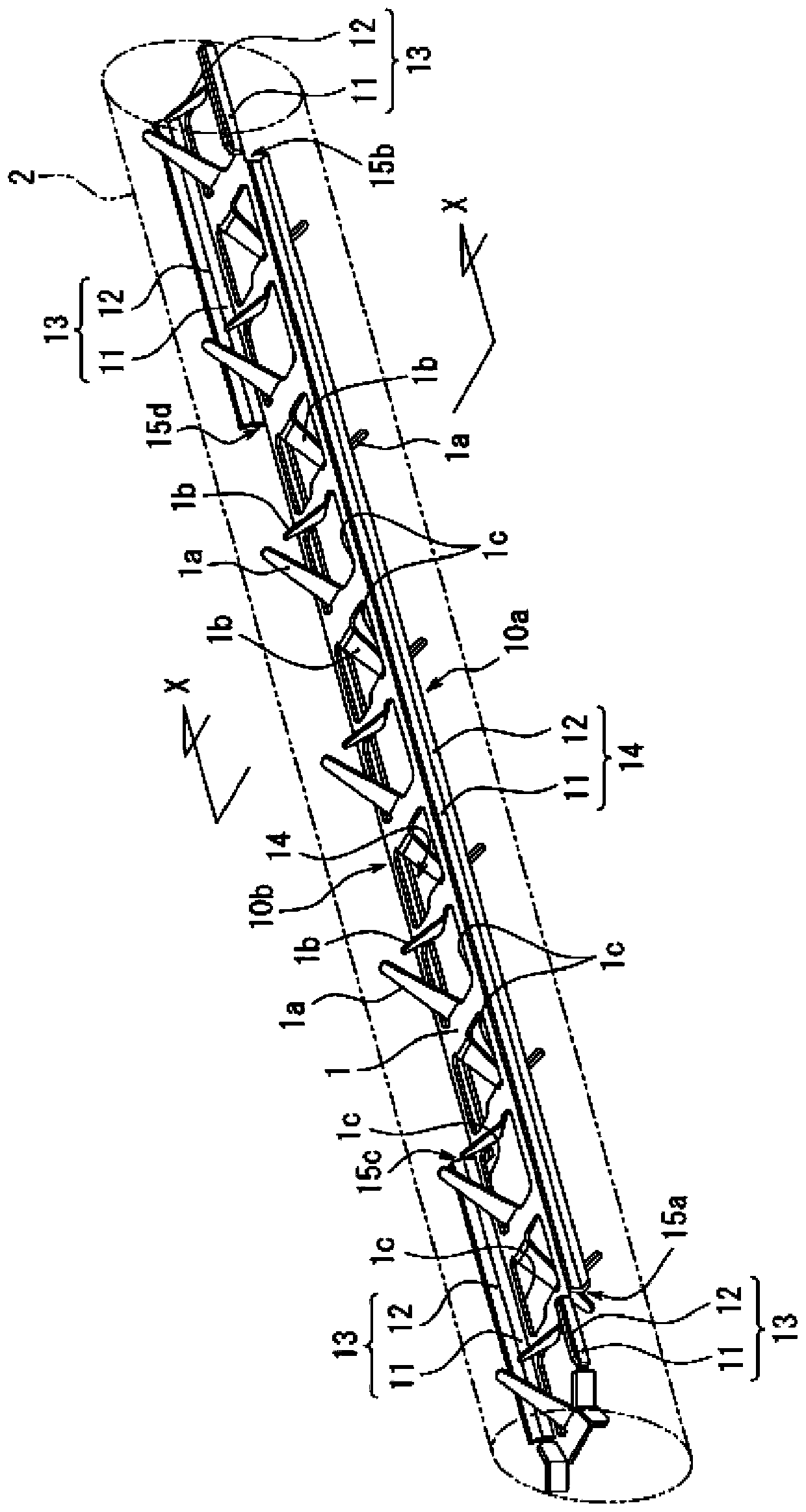

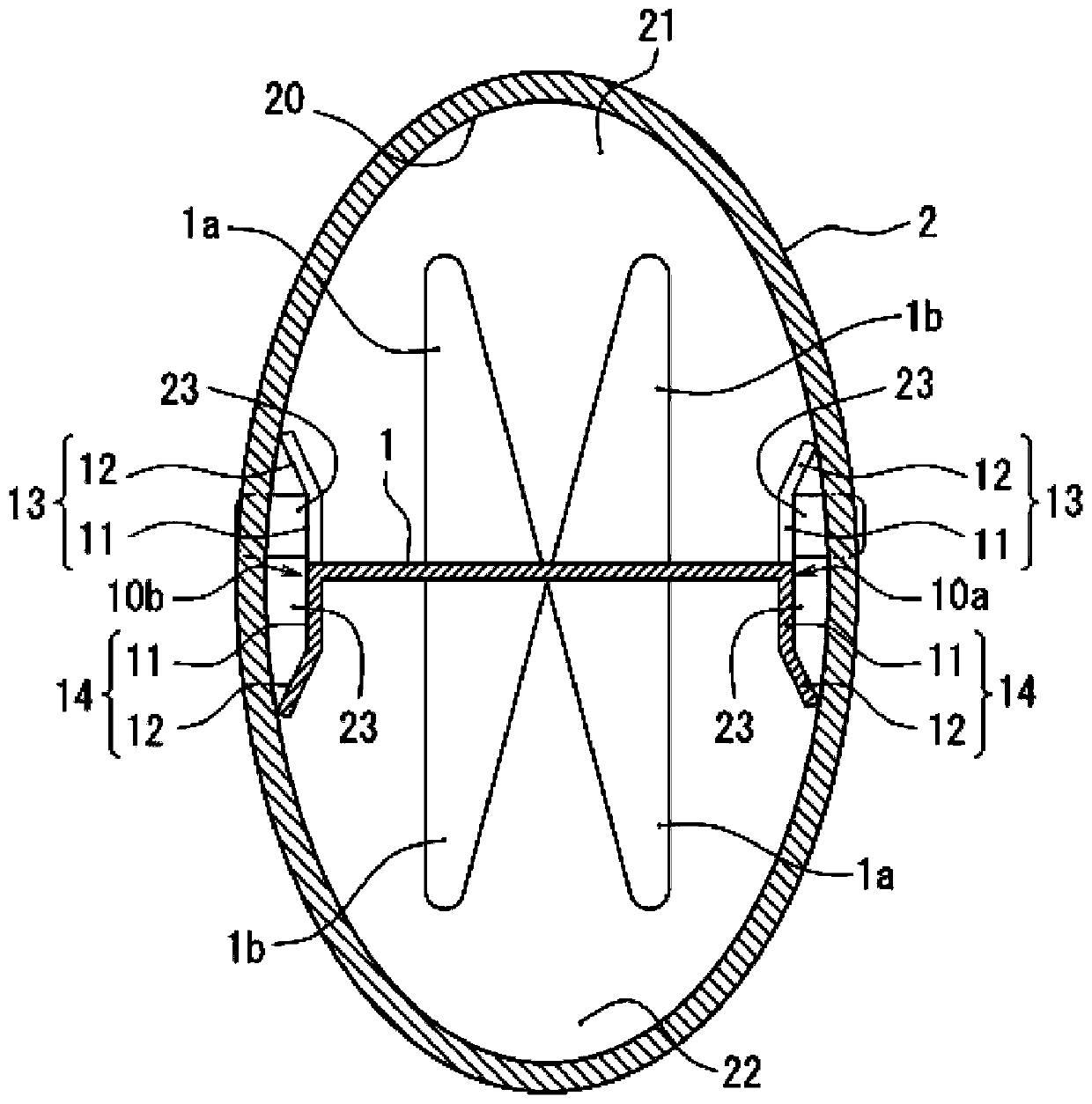

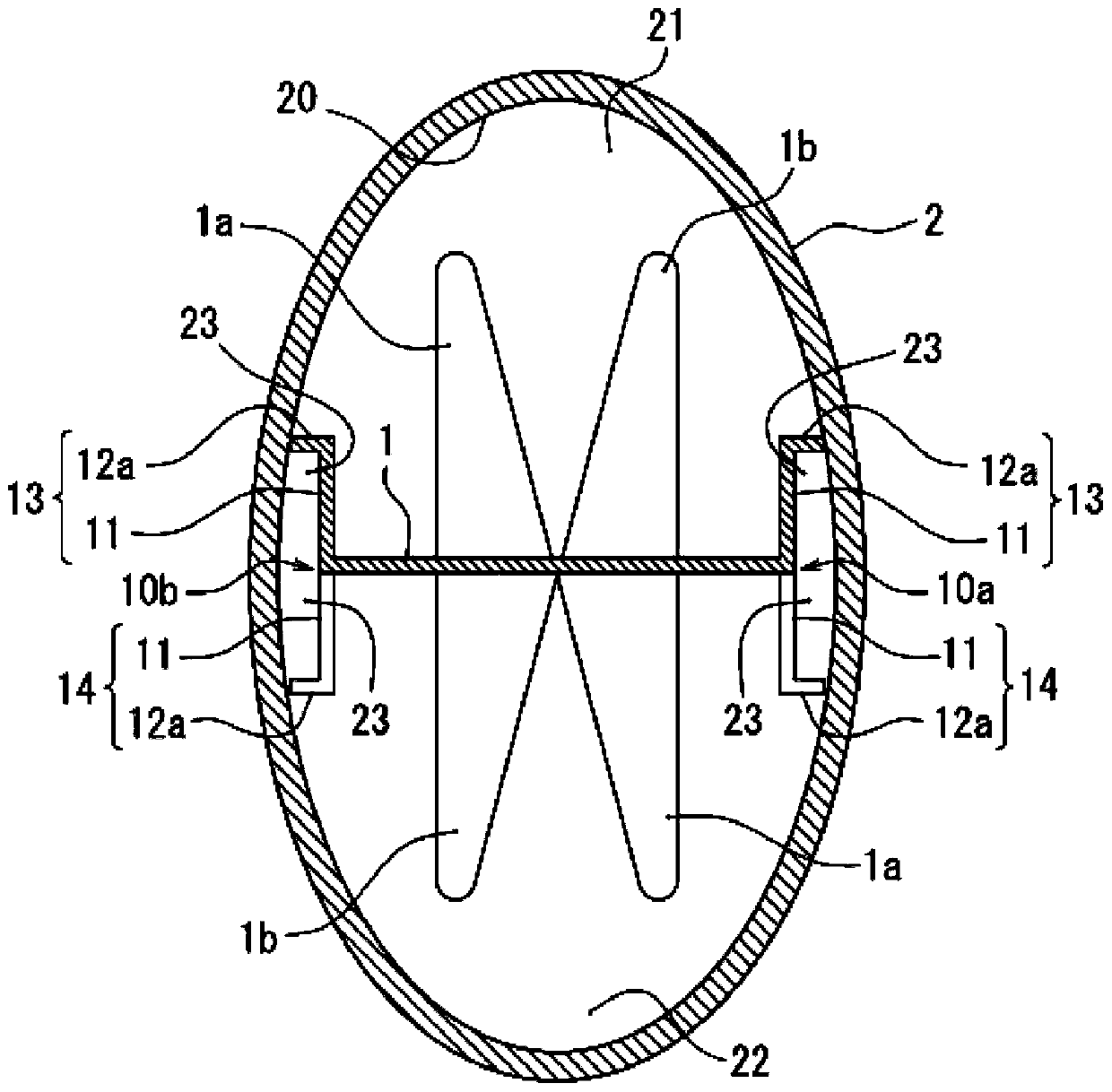

[0046] figure 1 It is a perspective view showing a state where the turbulent flow forming tool according to the first embodiment of the present invention is inserted into the heat transfer tube 2, figure 2 yes figure 1 Cross-sectional view of X-X.

[0047] The turbulent flow forming device of the first embodiment, such as figure 1 , figure 2 As shown, it is installed in the heat transfer tube 2 of the elliptical shape of the longitudinal section, and has a width that can be placed along the center line of the major diameter of the ellipse constituting the heat transfer tube 2 and is approximately consistent with the length of the heat transfer tube 2. Elongated flat part 1 constitutes. The plate part 1 can be made of stainless steel.

[0048]In the flat plate member 1, a plurality of through holes 1c consisting of cut holes and a plurality of protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com