Bi-direction balance type bellows compensator

A bellows, balanced technology, applied in the field of two-way balanced bellows compensator, can solve the problems of structural limitation, large size, enlarged bracket size, etc., and achieves the benefits of safe operation, reduced infrastructure costs, and small axial size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing.

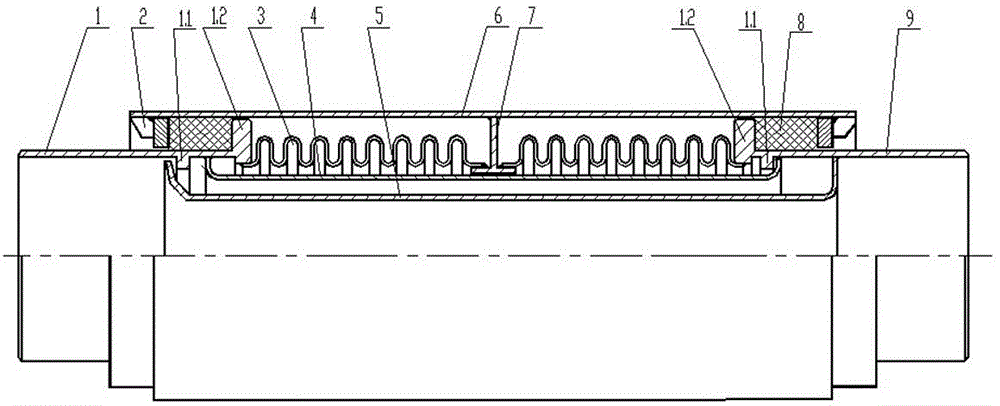

[0013] figure 1 The two-way balanced bellows compensator shown includes a left connecting pipe 1, a ring cover 2, a bellows 3, a guide pipe 4, an inner pipe 5, an outer pipe 6, a middle connecting pipe 7, a filler 8 and a right connecting pipe 9. The left connecting pipe 1 and the right connecting pipe 9 are both thin-walled pipes with the same caliber. The inner wall of the pipe is provided with a shoulder 1.1, and the outer wall of the pipe end close to the shoulder 1.1 is provided with a protruding flange edge 1.2. The coaxial left connecting pipe The thin-walled pipe ends of 1 and right connecting pipe 9 face away from each other, and are respectively coaxially sealed and connected to the bellows 3 in the inner hole of the flange side 1.2, and the middle connecting pipe 7 is sealed and connected to the other ends of the bellows 3 on both sides to form a conventional shaft The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com