Top and bottom composite rapping electric dust collector with variable rapping strength

A top-bottom composite, electrostatic precipitator technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of too small preset rapping force, anode plate dust accumulation, dust layer separation, etc. Simple, easy to make, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

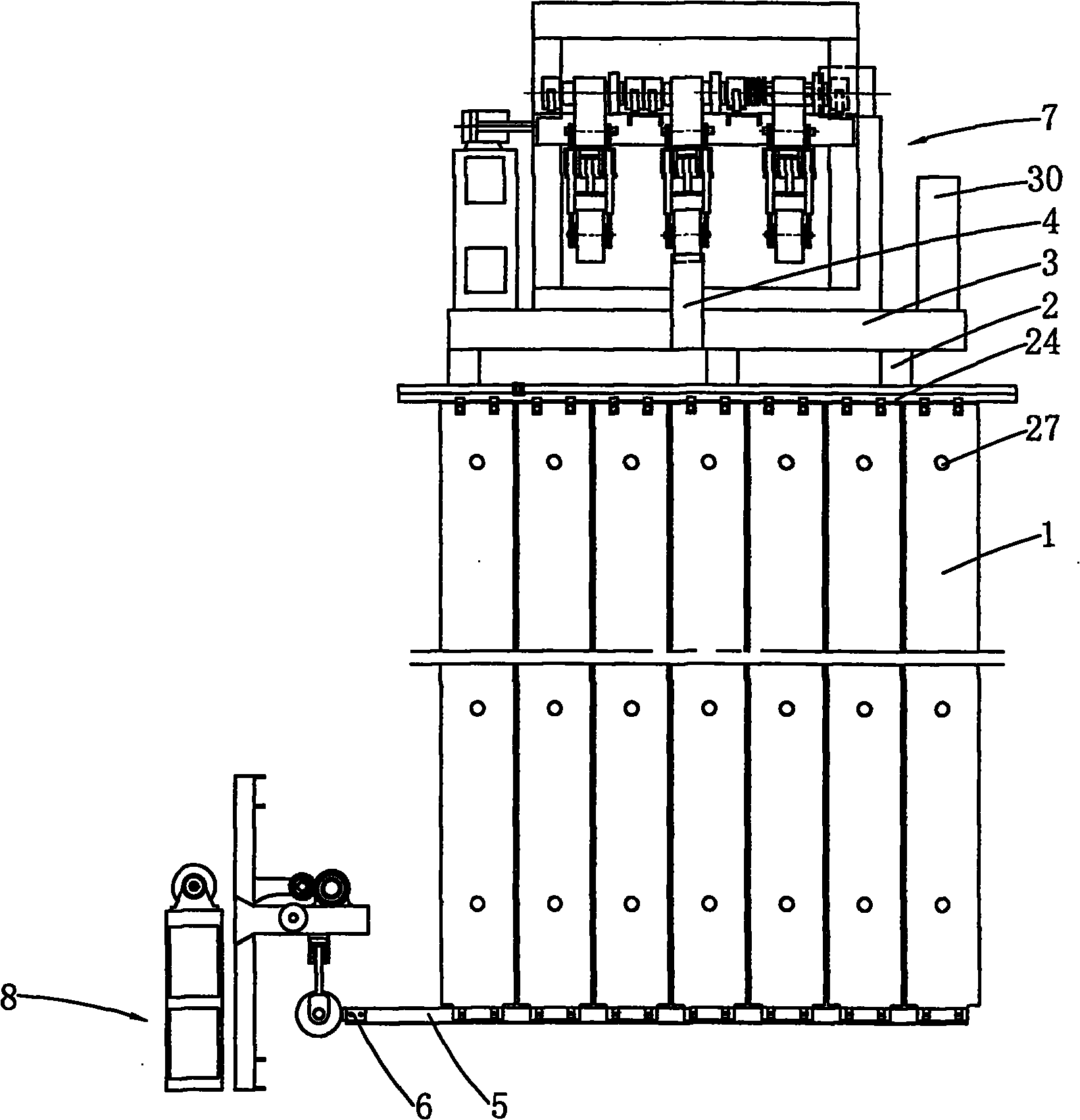

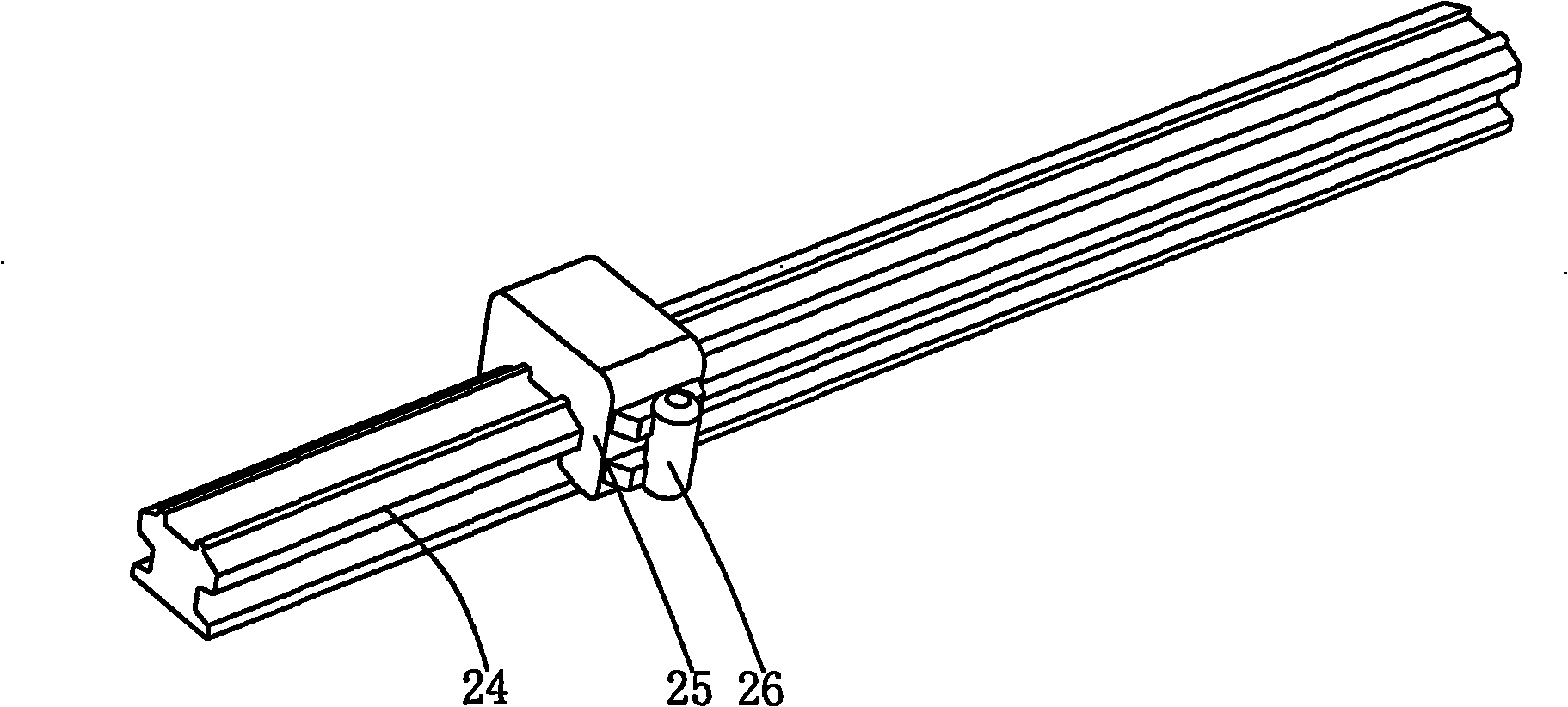

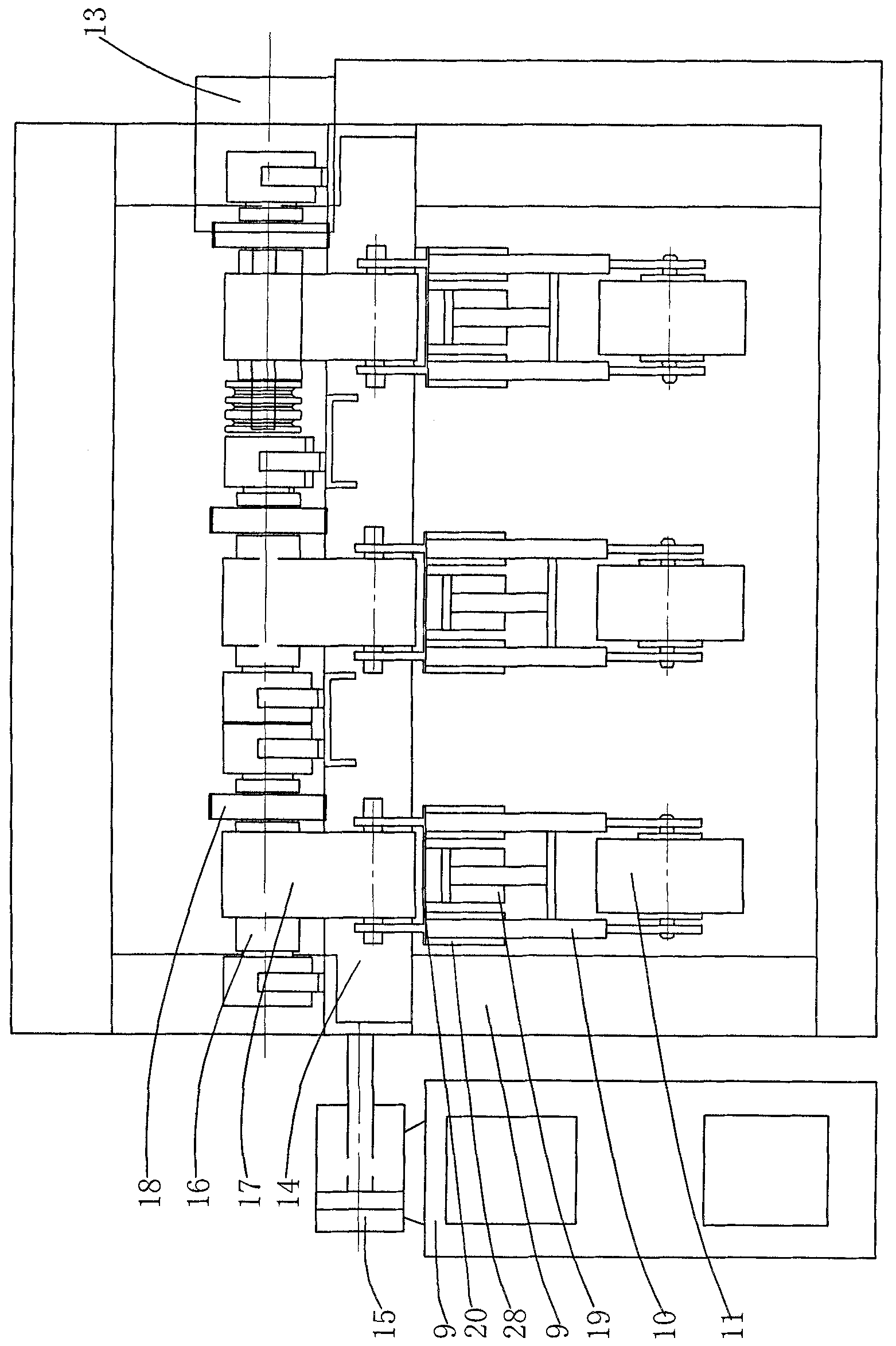

[0034] Such as Figure 1~2 As shown, a top-bottom composite rapping electrostatic precipitator with variable rapping intensity includes an anode plate 1, a support beam 2, a support plate 3, a top rapping anvil 4, a rapping rod 5, a bottom rapping anvil 6, The first rapping device 7, the second rapping device 8 and the computer system 30 are composed of parts such as, wherein an acceleration sensor 27 is arranged on the body of the anode plate 1, and a support beam 2 and a horizontal beam 24 are arranged on the top of the anode plate 1 . The support beam 2 is provided with the support plate 3, the top rapping anvil 4, the computer system 30 and the first rapping device 7 are installed on the support plate 3, and the first rapping device (7) is positioned at the top rapping At the rear of the anvil (4), the computer system (30) is located on the right side of the first rapping device (7). The cross-section of the horizontal beam 24 is "I"-shaped, and a mounting seat 25 is loo...

Embodiment 2

[0050] Such as Figure 8 As shown, at least 3 rapping units are arranged side by side on the mounting base 14 from left to right. In this embodiment, the number of rapping units is 4, and the specific number can be adjusted accordingly according to the actual situation. The rest of the structure of the example is exactly the same as that of the first example, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com