Ash cleaner for dust-removal filter bag

A technology of dust cleaner and filter bag, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of inability to clean dust with cloth bags, increase the production cost of enterprises, and fail to achieve, so as to shorten downtime and replace The effect of reducing the time of cloth bags, saving production costs and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

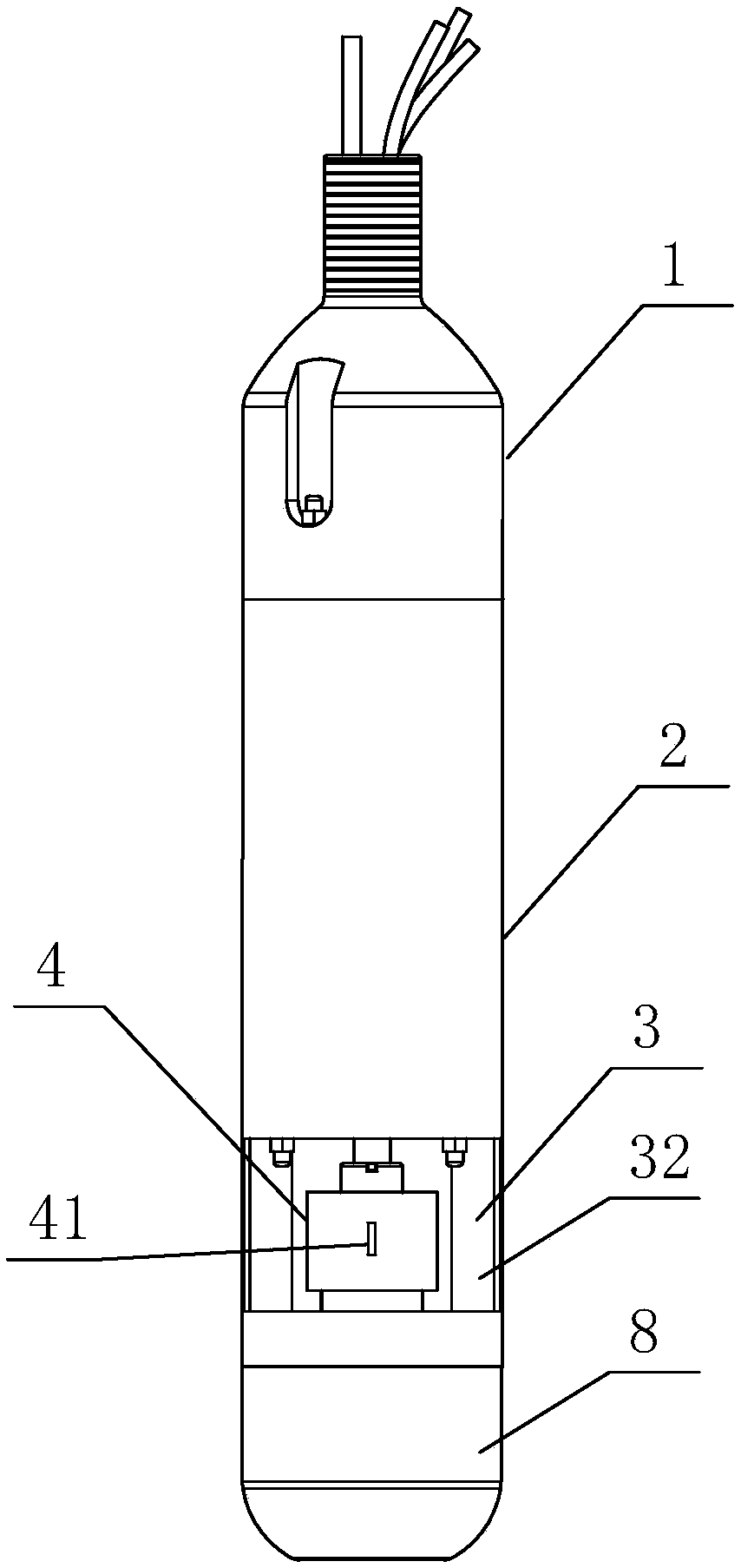

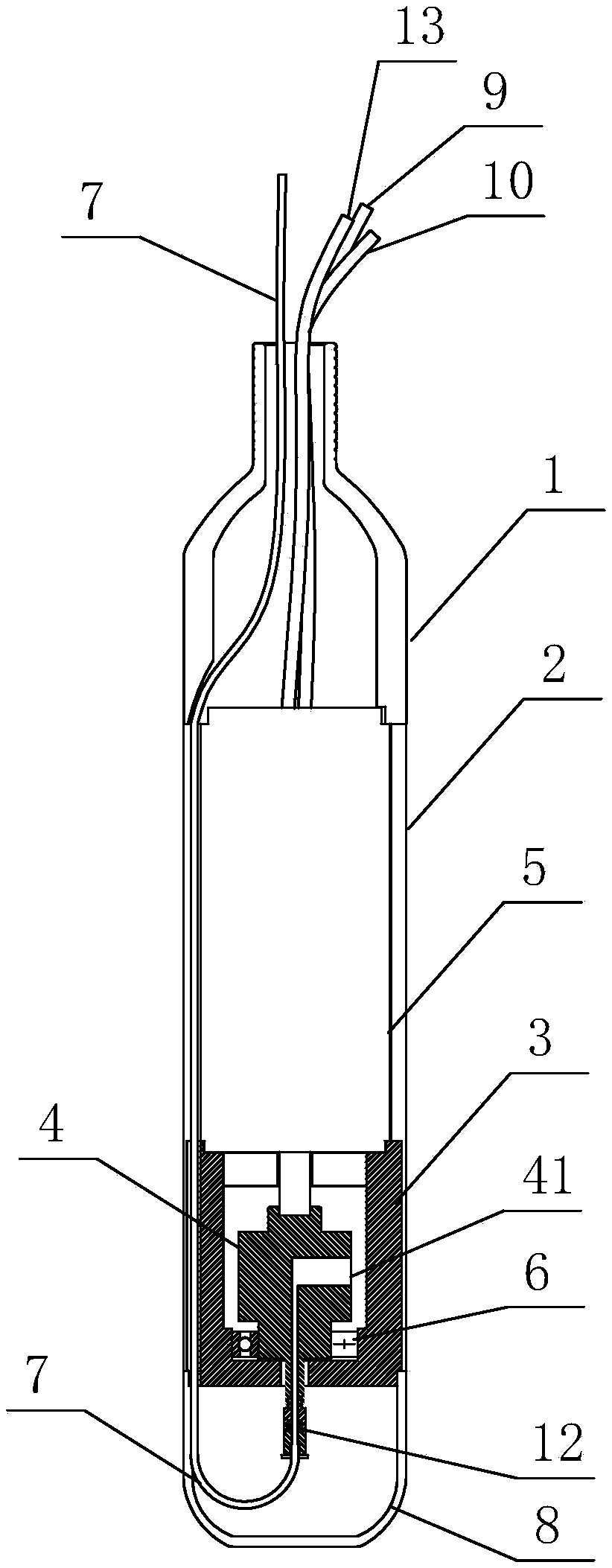

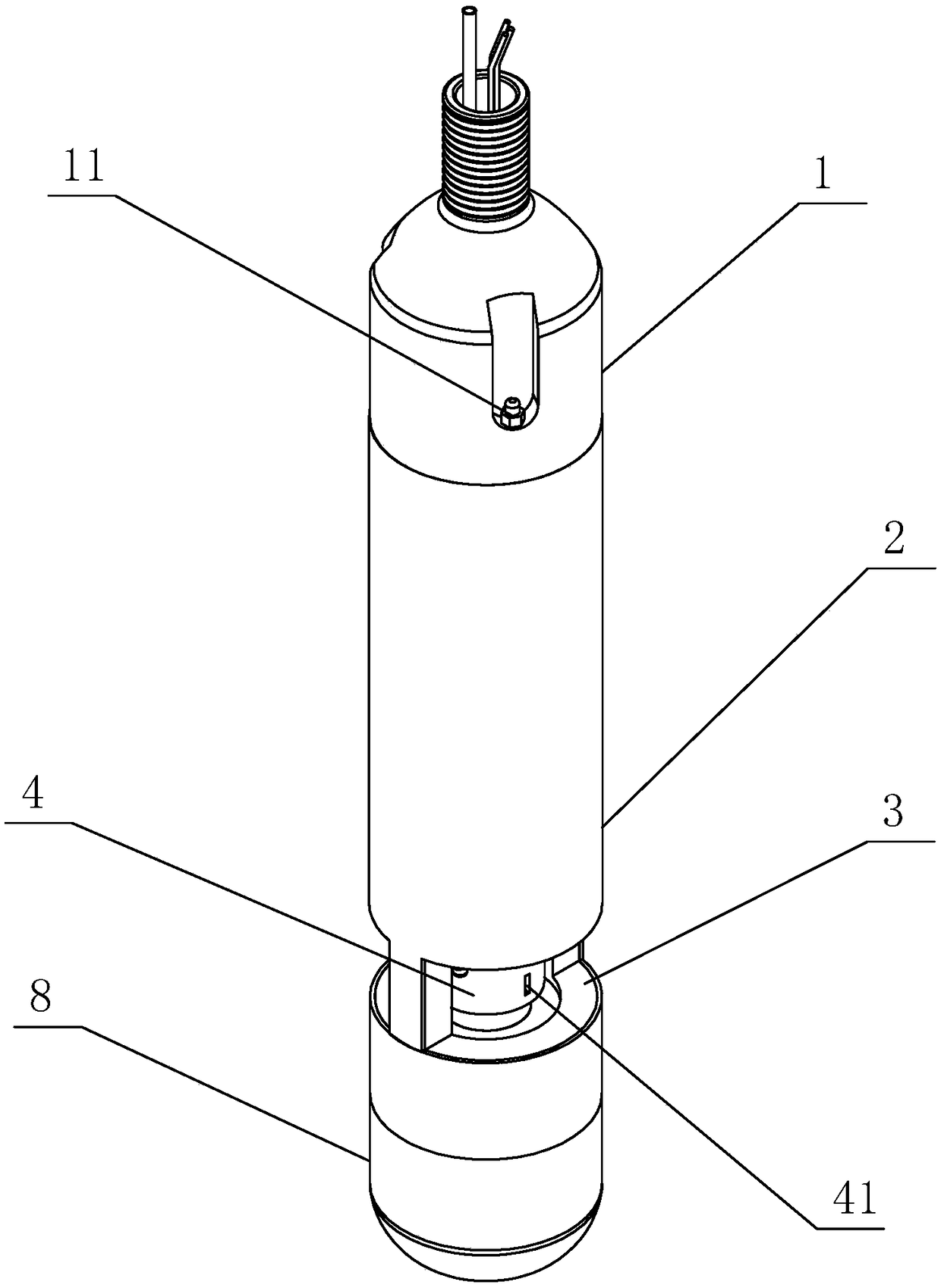

[0024] Such as Figure 1 to Figure 3 As shown in the figure, a dust filter bag cleaning device, the main body is in the shape of a cylinder, which is convenient to extend into the cloth bag, including a top cover 1, a housing cover 2, a base frame body 3, an air drum 4, a motor 5, and an air pipe 7 and the bottom cover 8; the motor in the present embodiment selects the motor that has the water inlet pipe 9 and the water outlet pipe 10 that can run at high speed. The motor generates heat and relies on water to take away the heat directly as the medium for cooling. When the motor is running, The water inlet pipe 9 is connected to the water source, and the water in the water outlet pipe 10 directly takes away the heat generated by the motor, which can prevent the motor from overheating and maintain a good running state. The motor of the present invention can also be a non-water-cooled motor with high temperature resistance.

[0025] The housing cover 2 is arranged between the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com