Combined type electric deduster

An electrostatic precipitator and combined technology, which is applied in the field of dust collection devices, can solve the problems of arcuate deformation of cathode wires, high cost of cathode insulating sleeves, difficulty in ensuring errors due to changes in the distance between anode plate frames and cathode wire frames, etc. The effect of pulling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In this example,

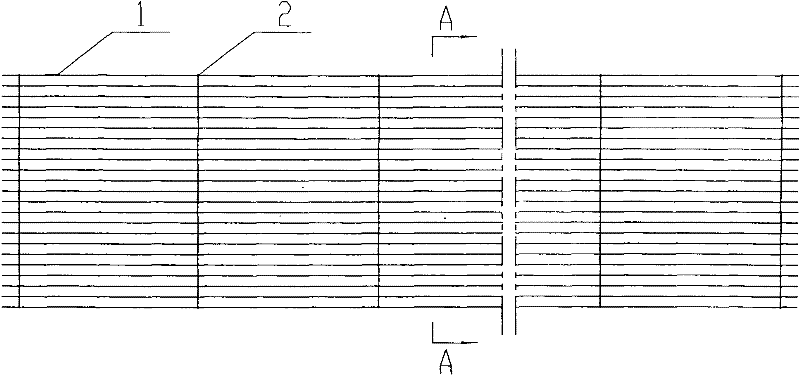

[0073] Such as figure 1 As shown, it is a transparent anode plate (3) made of U-shaped metal laths (1), arranged and combined at equal intervals, connected and fixed by positioning pins (2).

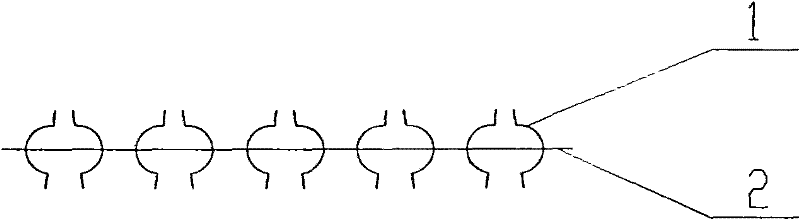

[0074] Such as figure 2 shown; is figure 1 In the embodiment 1 of the transparent anode plate in the present invention in A-A, U-shaped metal laths (1) are used, which are equally spaced, each of which is alternately arranged and combined with each other repeatedly, and is connected and fixed by positioning pins (2). Transverse sectional view of the through-type anode plate (3).

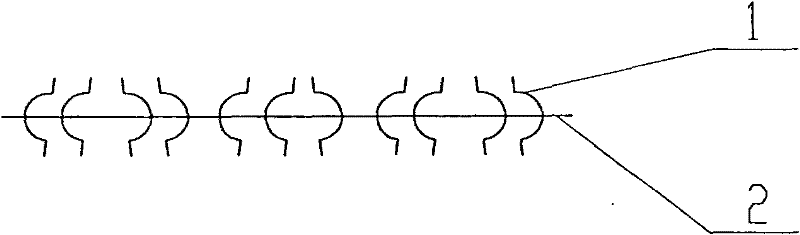

[0075] Such as image 3 shown; is figure 1 The second embodiment of the transparent anode plate in the present invention in A-A is made by using U-shaped metal laths (1), equidistant, every two alternately arranged and combined with each other, and connected and fixed by positioning pins (2) Transverse sectional view of the transparent anode plate (3).

[0076] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com