Assemble type shading baffle convenient to assemble and disassemble

A prefabricated and baffle technology, which is applied in the direction of sunshade, construction, building structure, etc., can solve the problems of difficult installation and disassembly by installers, large volume of shading baffle, and reduced assembly efficiency, so as to avoid falling accidents and facilitate The effect of adjusting operation and improving safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

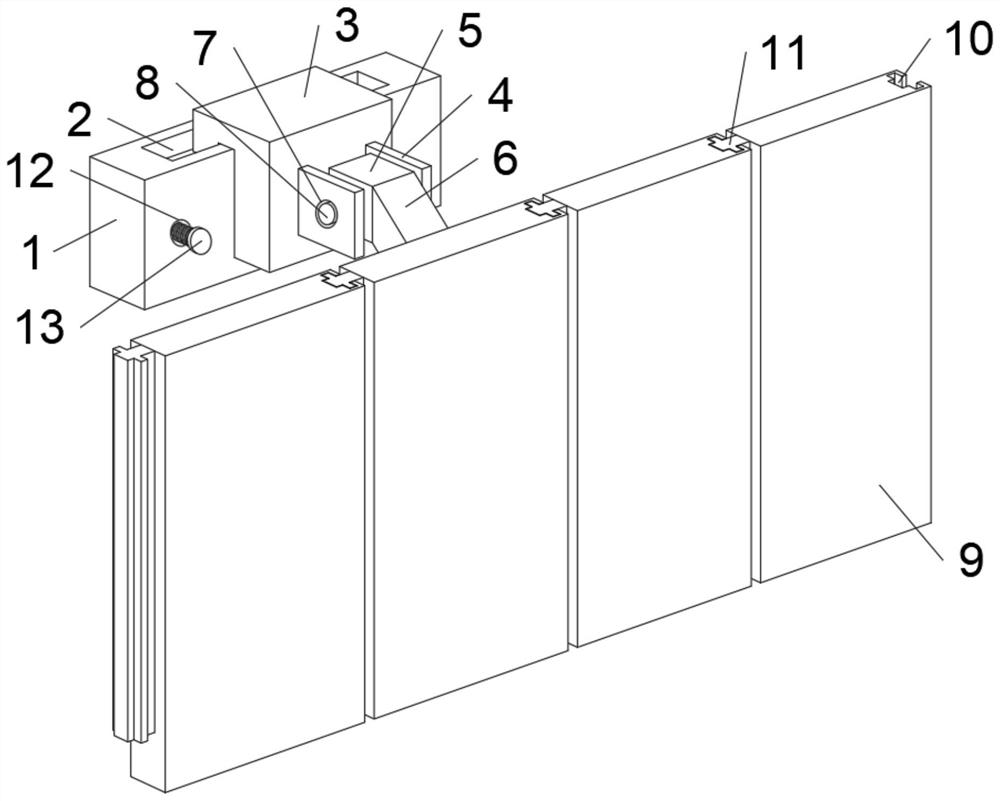

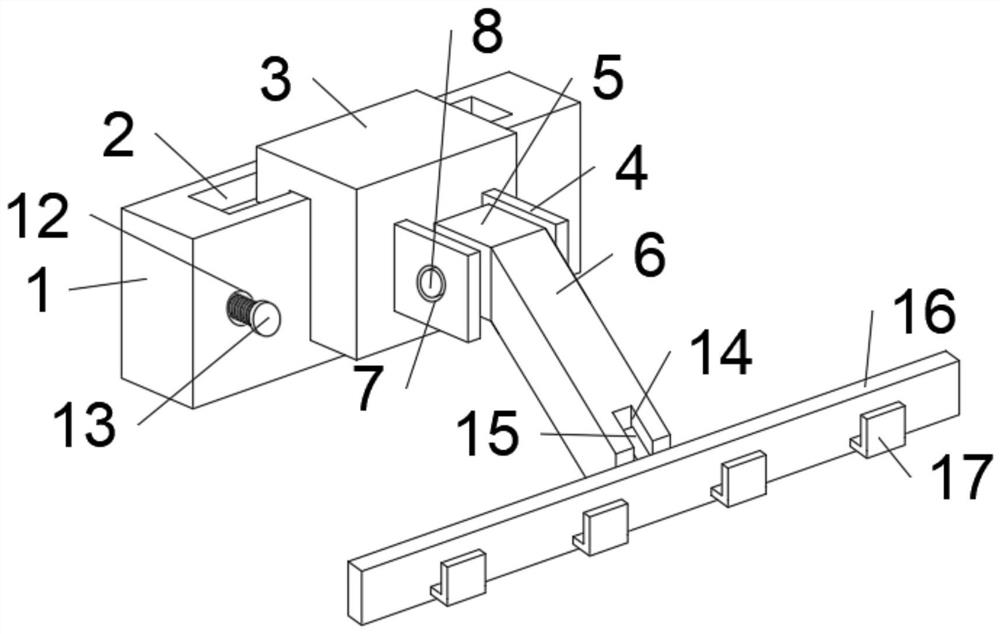

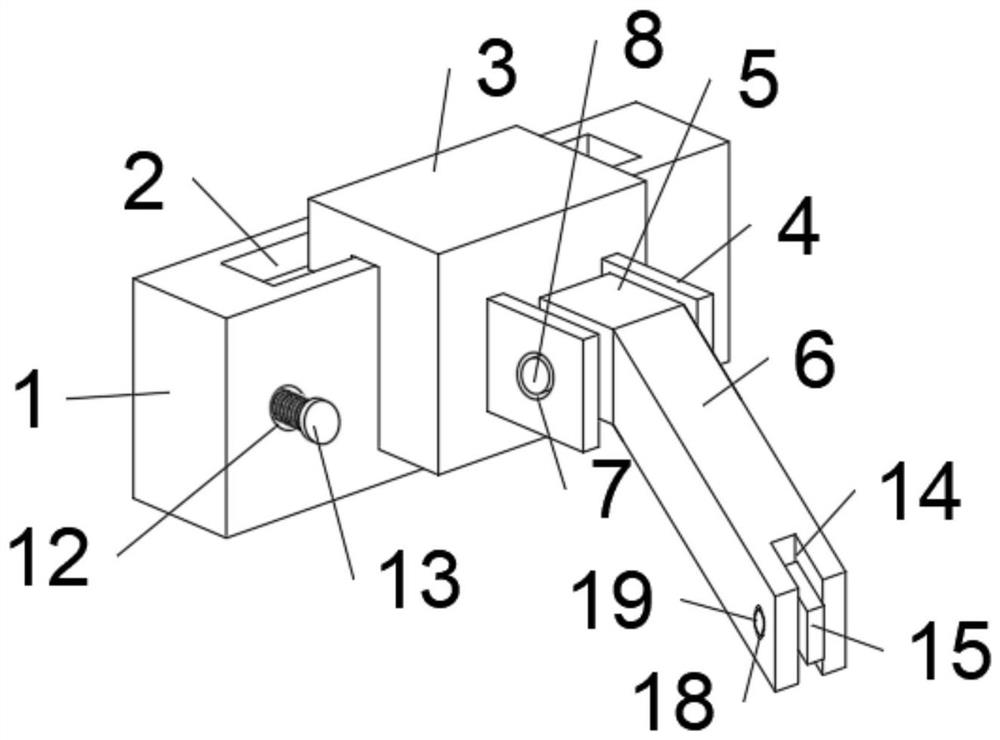

[0032] like Figure 1-Figure 7 As shown, the assembled shading baffle provided by this embodiment is easy to assemble and disassemble, including a mounting base 1 and a shading baffle 9, the mounting base 1 is connected with a fixed block 3 through a slot 2, and the slot 2 is set on The upper end surface of the mounting base 1, the card slot 2 and the fixed block 3 are compatible, and the front side of the mounting base 1 is provided with symmetrically distributed expansion bolt holes 12, and the expansion bolt holes 12 are internally screwed with expansion bolts fixedly connected to the wall surface. Before installing the bolt 13 and the shading baffle 9, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com