Moving bed reactor for medium temperature dry distillation

A moving bed reactor, medium temperature technology, applied in the direction of special dry distillation, direct heating dry distillation, petroleum industry, etc., can solve the problems of poor air permeability of the material layer, poor air flow, low yield of tar and gas, etc., to improve heat transfer Efficiency, smooth movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

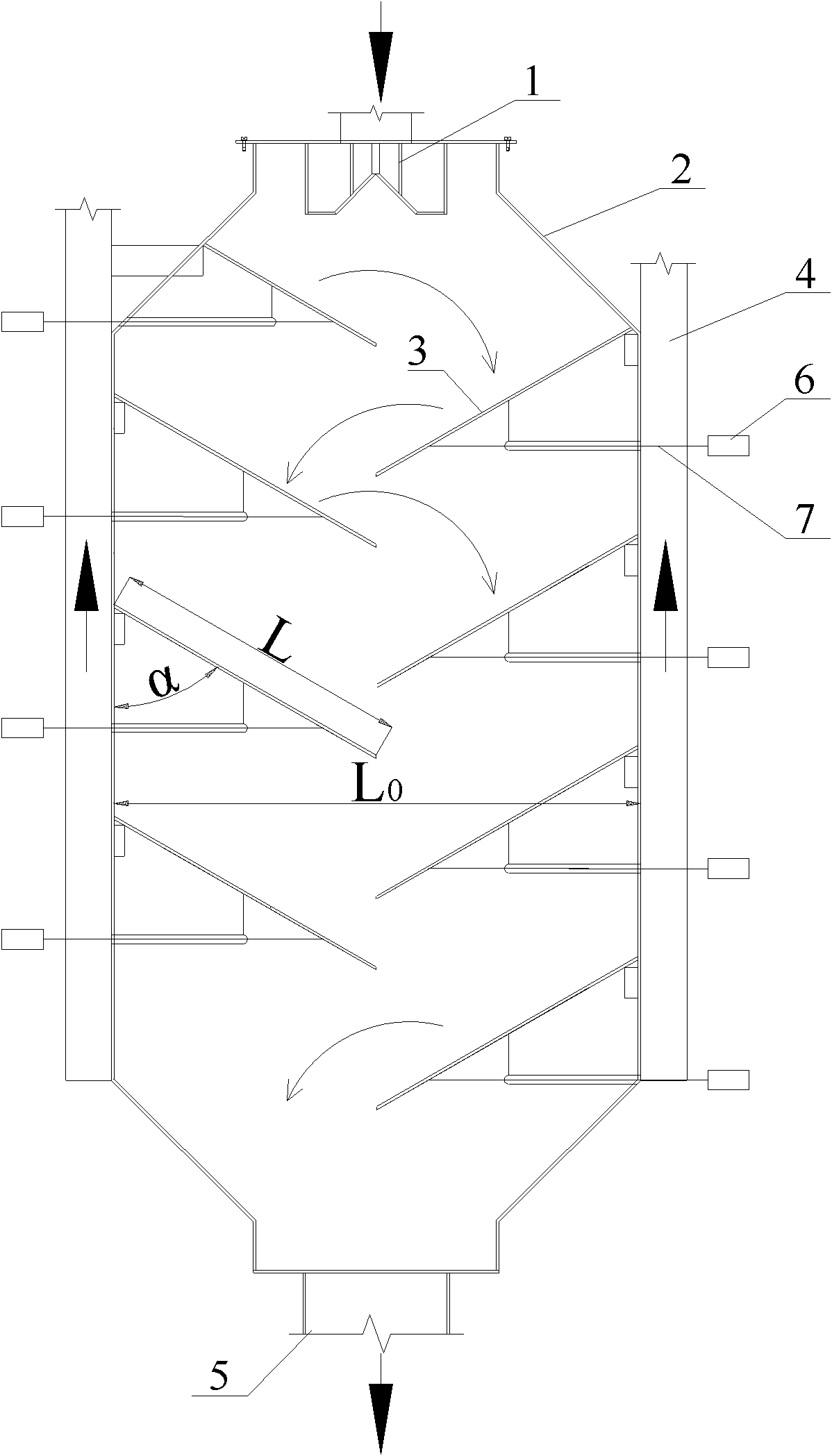

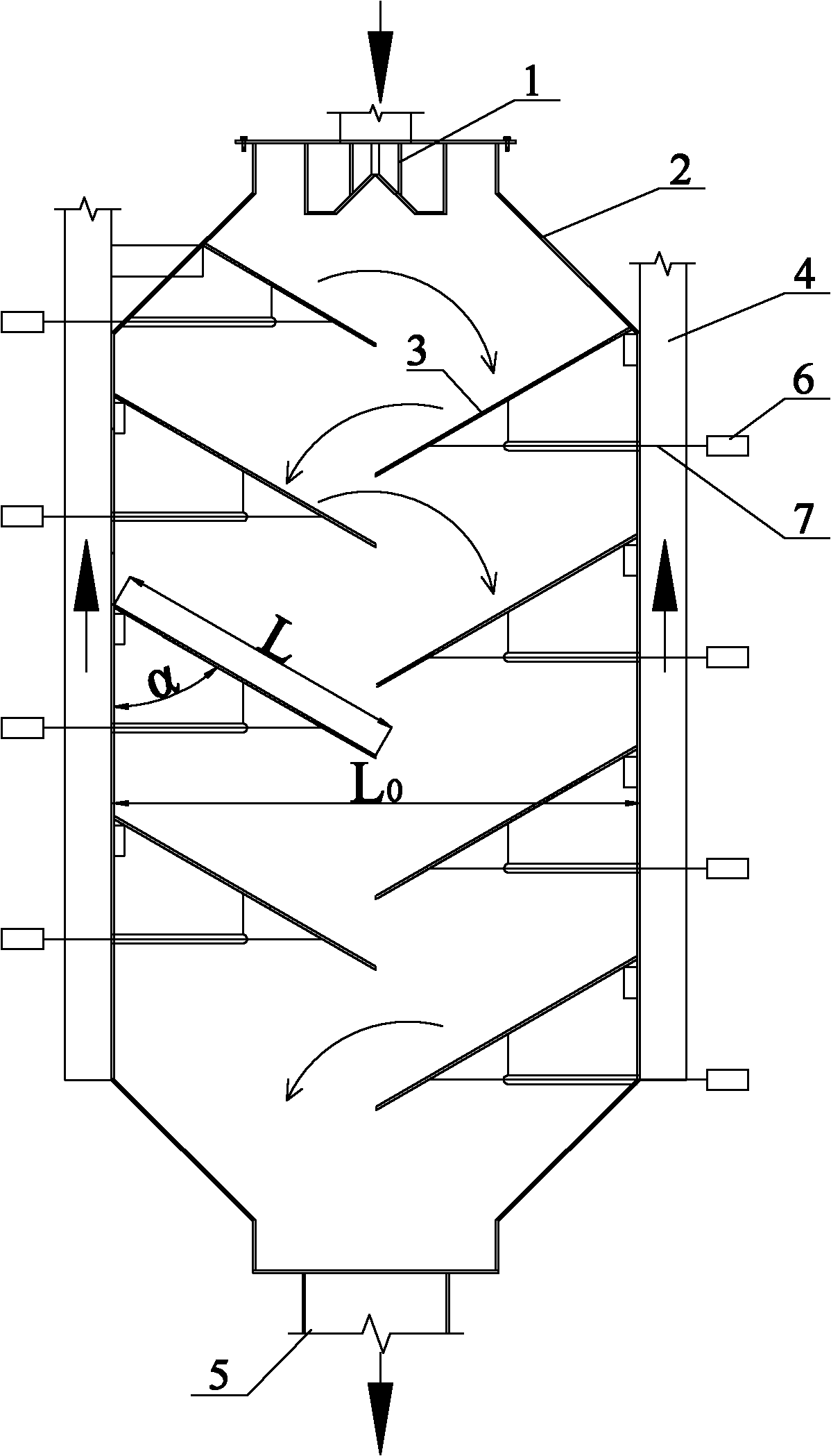

[0013] Describe structure, working principle and working process of the present invention in detail below in conjunction with accompanying drawing:

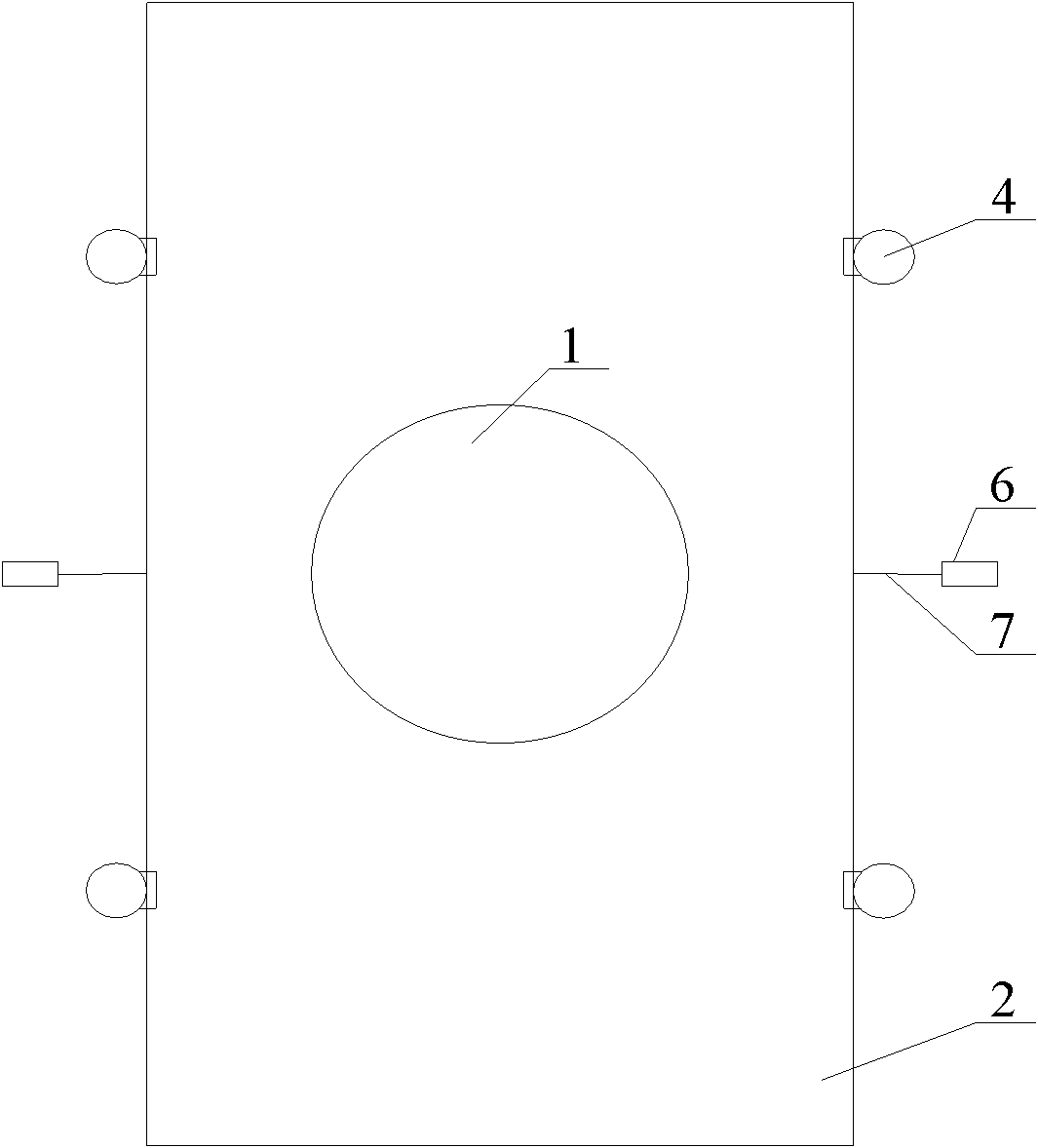

[0014] A moving bed reactor for medium temperature dry distillation according to the present invention, the reactor comprises a shell 2, a feeder 1 arranged at the top of the shell 2 and a material outlet 5 arranged at the bottom of the shell 2, A plurality of downward-sloping baffles 3 are arranged inside, and an air pipe 4 and a rapping device 6 are arranged outside the shell; The air pipe and the exhaust pipe pass through the housing 2 and communicate with the air pipe 4; the rapping device 6 is arranged on the outside of the housing 2, and each baffle corresponds to one or a group of rapping devices, and the baffle passes through the The transmission rod 7 is connected with the rapping device.

[0015] In the present invention, the shell 2 can adopt a circular or square structure; when a square is adopted, the angle α betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com