Cyclone electric-bag pulse filter cylinder separator

A filter cartridge dust collector and electric bag technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of large air leakage rate, not meeting the actual use requirements, and large investment in the dust removal system. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described below in conjunction with specific embodiments.

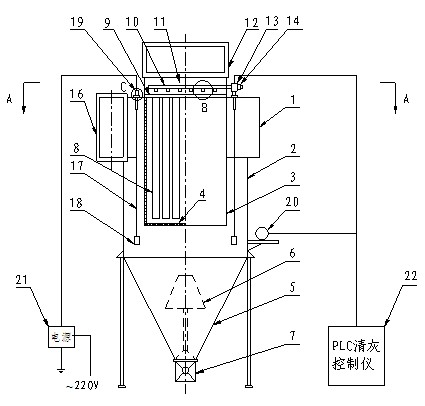

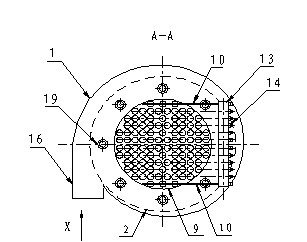

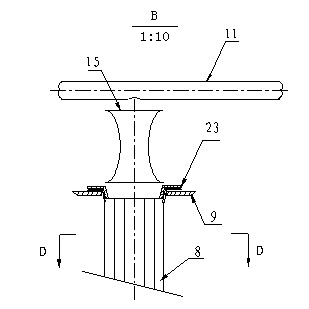

[0031] Such as figure 1 As shown, it is a structural schematic diagram of the cyclone electric bag pulse filter cartridge dust collector according to the present invention. figure 2 Shown is its A-A sectional view, image 3 It is a local enlarged figure B, Figure 4 Its local enlarged figure C, Figure 5 Its D-D sectional view. The cyclone electric bag pulse filter cartridge dust collector of the present invention comprises from top to bottom: an upper volute 1 , a lower outer cylinder 2 , a lower ash hopper 5 , and a discharger 7 . The upper volute 1 is located at the upper end of the dust collector, and the upper volute 1 is provided with an air inlet 16, and the air containing a large amount of dust flows along the figure 2 The X direction in enters the upper volute 1. The lower part of the upper volute 1 is provided with a lower outer cylinder 2, and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com