DC superposed pulse electric precipitation method

A technology of DC superimposition and pulse electricity, which is applied in the application of electrostatic dust removal generated by high-power power supply devices, in the field of high-voltage electrostatic dust removal, to achieve high power supply efficiency, expand the application range, and reduce the effect of secondary flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

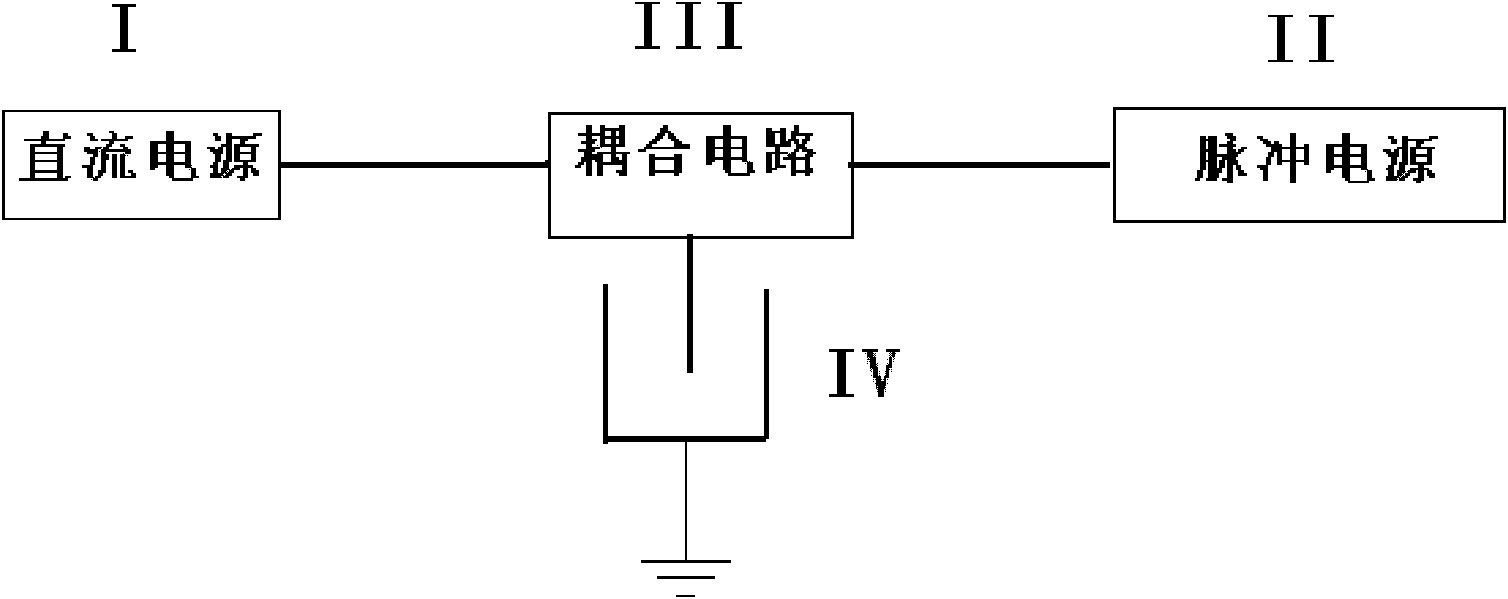

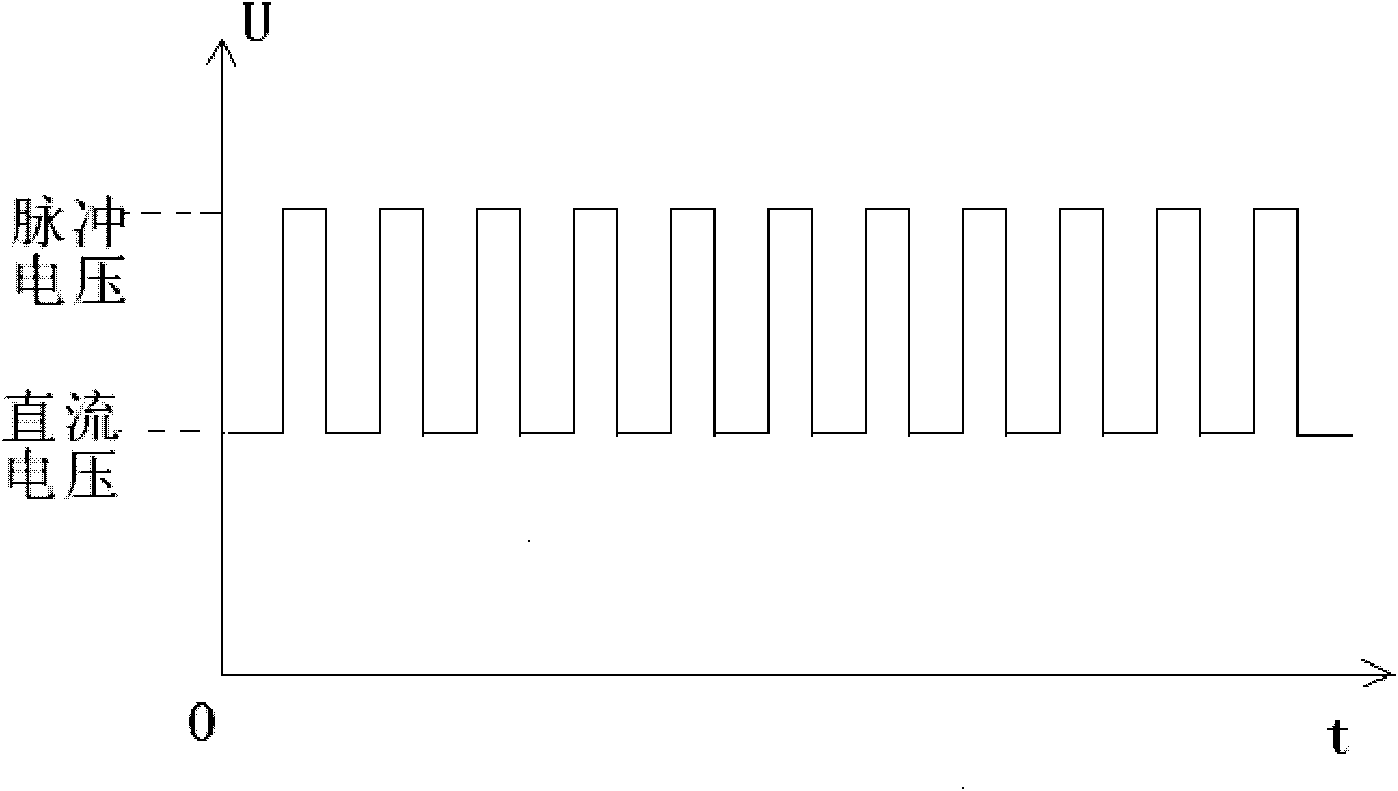

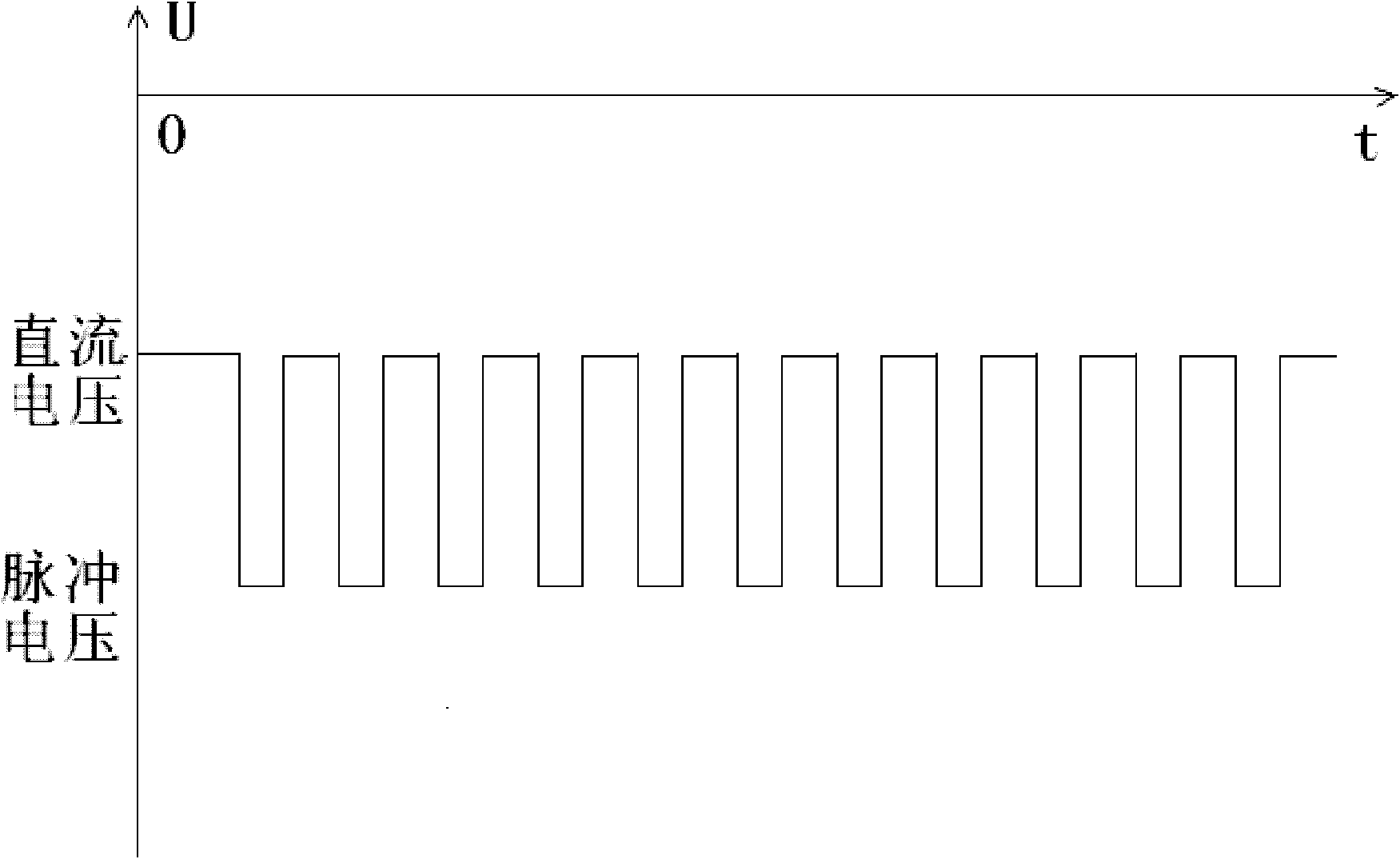

[0017] Hardware of the present invention see figure 1 , including DC power supply Ⅰ, pulse power supply Ⅱ, coupling circuit Ⅲ and electrostatic precipitator reaction device Ⅳ. A sampling control unit can also be set to sample the voltage acting on the dedusting reactor and feed back to fine-tune the power supply voltage. Refer to Fig. 2 for the voltage waveform on the reaction device, wherein Fig. 2(a) is a positive polarity voltage, and Fig. 2(b) is a negative polarity voltage.

[0018] Among them, DC power supply Ⅰ and pulse power supply Ⅱ are independent and adjustable. In the power supply, the DC voltage generated by the DC power source I and the pulse voltage generated by the pulse power source II are superimposed through the coupling circuit, and act on the dust removal reaction device IV. The pulse voltage combines the charge with the flue gas dust and fine particles, and then the electrostatic adsorption effect of the electric field generated by the DC voltage adsorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com