Shaking and deashing mechanism special for filtering cartridge type dedusting and purifying equipment

A technology of dust removal mechanism and purification equipment, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of lack of dust separation mechanism, achieve good dust effect, long service life, and ensure reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

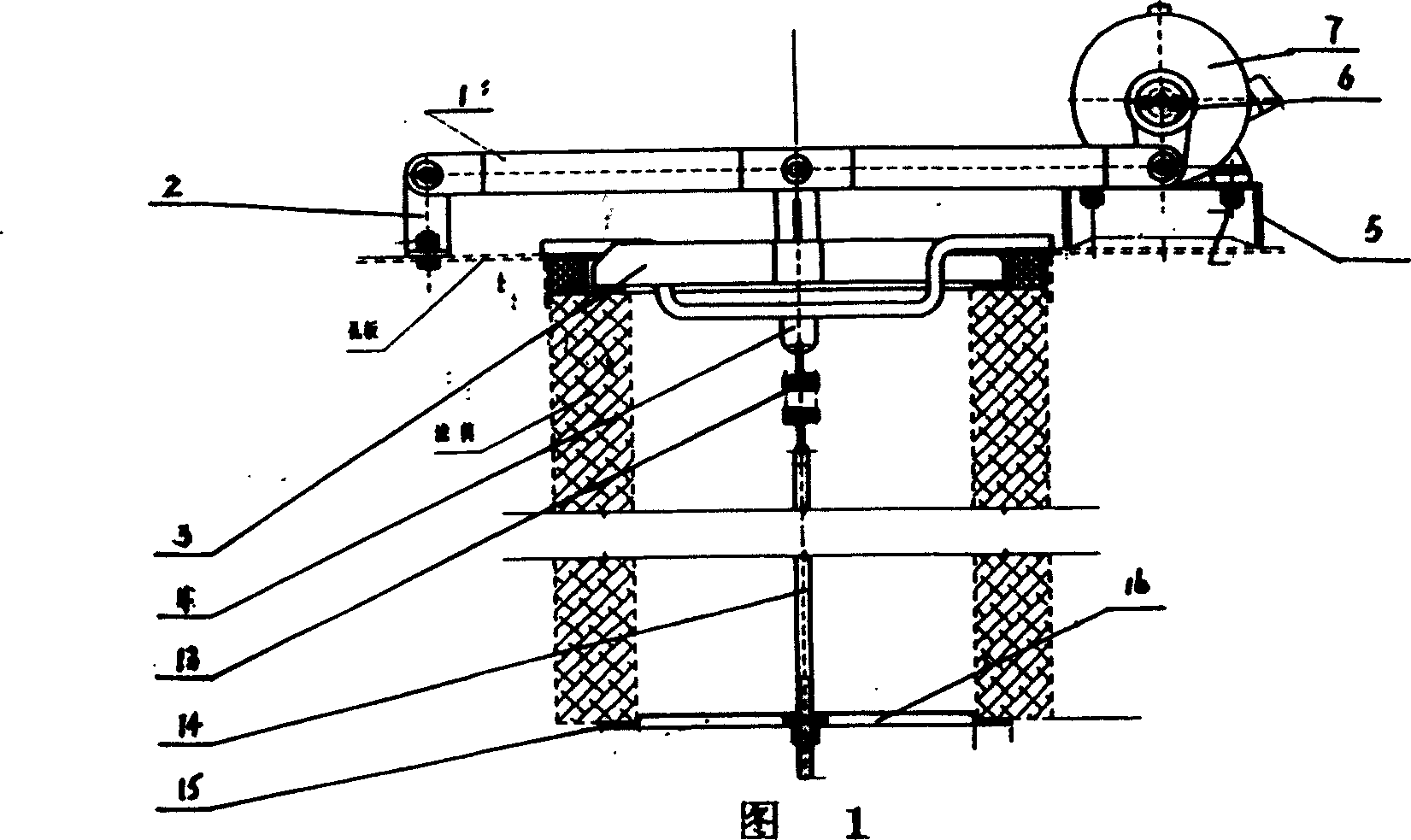

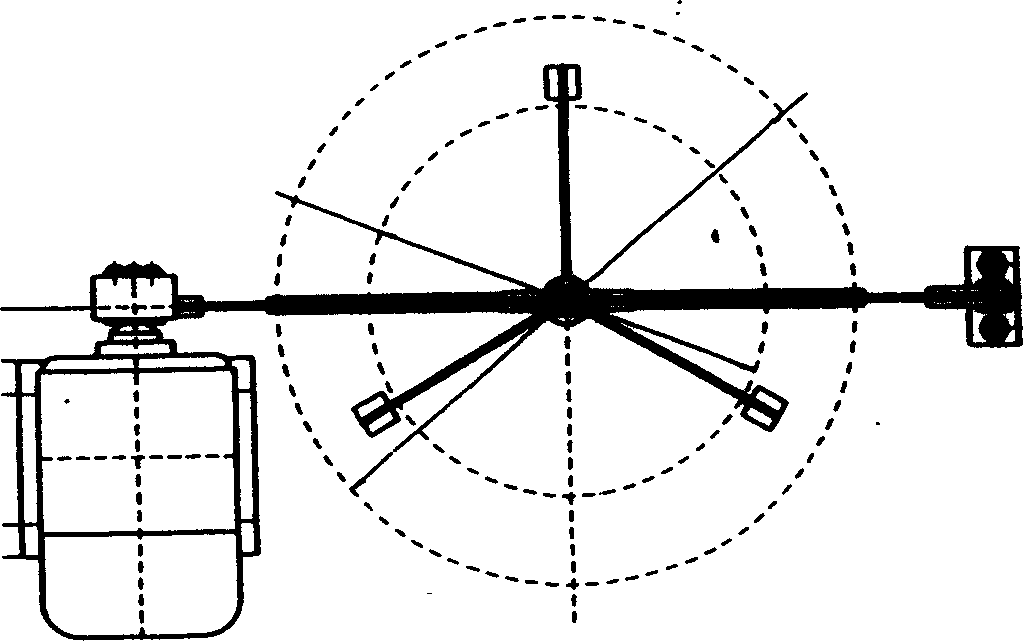

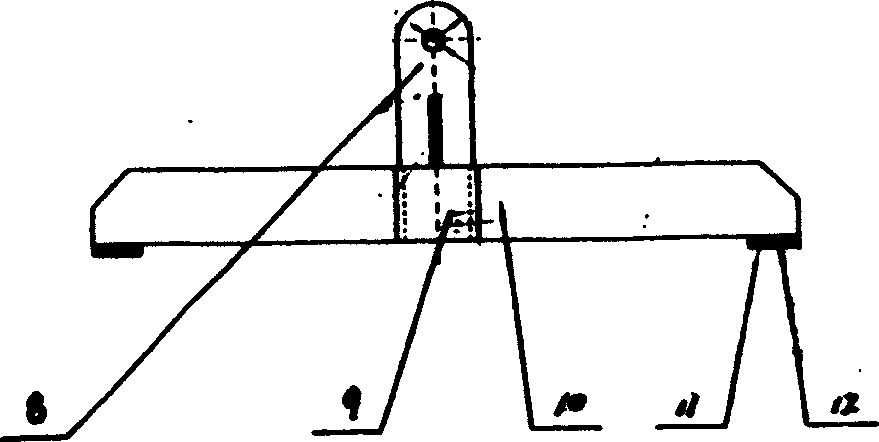

[0010] Embodiment 1: The special vibrating and dust-cleaning mechanism for filter cartridge type dust removal and purification equipment is composed of positioning foot 2, connecting rod 1, eccentric mechanism 6, vibrating pressing frame 3 and motor 7. The eccentric mechanism 6 is driven by the motor 7, and the motor 7 is fixed on the On the motor chassis 5, one end of the connecting rod 1 is pinned to the transmission plate in the eccentric mechanism, and the other end is pinned to the positioning foot 2, and the straight plate 8 in the vibrating press frame 3 collides intermittently with the vibrating block in the middle of the connecting rod. Cooperate, the rapping frequency of the collision rapping dust cleaning mechanism is 500-2900 times / min (500 times / min, 800 times / min, 1000 times / min, 1200 times / min, 1500 times / min, 1800 times / min, 2000 times / min, 2300 times / min, 2600 times / min, 2900 times / min). Referring to accompanying drawings 1-4. The eccentric shaft deviates fro...

Embodiment 2

[0011] Embodiment 2: The rapping method of the special rapping and dust-cleaning mechanism for filter cartridge type dust removal and purification equipment. While acting on the upper port of the filter cartridge, press the filter cartridge down by 1-5mm, and the telescopic pad located on the periphery of the vibrating press frame will elongate or reset with the displacement of the filter cartridge. The reset of the filter cartridge is completed by the return spring, and the filter cartridge Hanging on the hanger, the hanger is fixed on the grooved elbow, and the grooved elbow is fixed on the orifice plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com