Automatic backwashing filter

A backflushing and filter technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems that the filter cannot remove sulfur-containing and nitrate-containing pollutants, and the delay of differential pressure monitoring is inaccurate, and achieves The effect of timely and accurate pressure monitoring and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

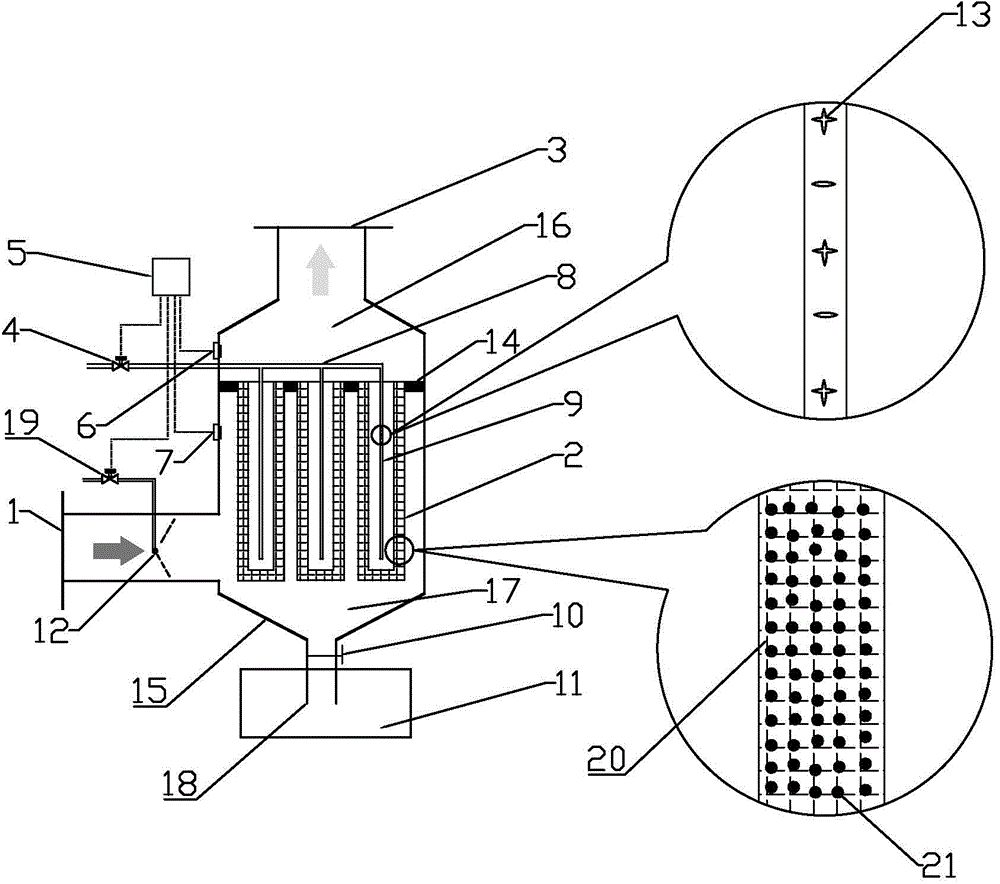

[0022] Such as figure 1 As shown, an automatic backflushing filter includes a housing 15, a ceramic filter 2, a filter fixing plate 14 and a control unit 5, the housing 15 is provided with an exhaust gas inlet 1 and an exhaust gas outlet 3, and the filter fixing plate 14 Divide the space inside the housing 15 into an upper clean gas chamber 16 and a lower dust-laden gas chamber 17, and the opening end of the ceramic filter 2 is fixed on the filter fixing plate 14 toward the clean gas chamber 16, including back blowing Washing pipe 9, one end of the backflushing pipe 9 is located in the ceramic filter 2, and the other end is connected to the compressed air main pipe 8, the compressed air main pipe 8 is provided with a compressed air control valve 4, and the bottom of the housing is provided There is a dust discharge port 18 controlled by a dust discharge valve 10, a dust-containing gas pressure sensor 7 is provided in the dust-containing gas chamber 17, a clean gas pressure sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com