Automatic shaking-up device for volumetric flask after constant volume treatment

A volumetric flask and constant volume technology, which is applied in the field of inspection and testing, can solve problems such as the impact of experimental work, no protection mechanism, solvent spillage, etc., to meet diverse needs, facilitate installation and disassembly, and avoid the troublesome effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] To make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

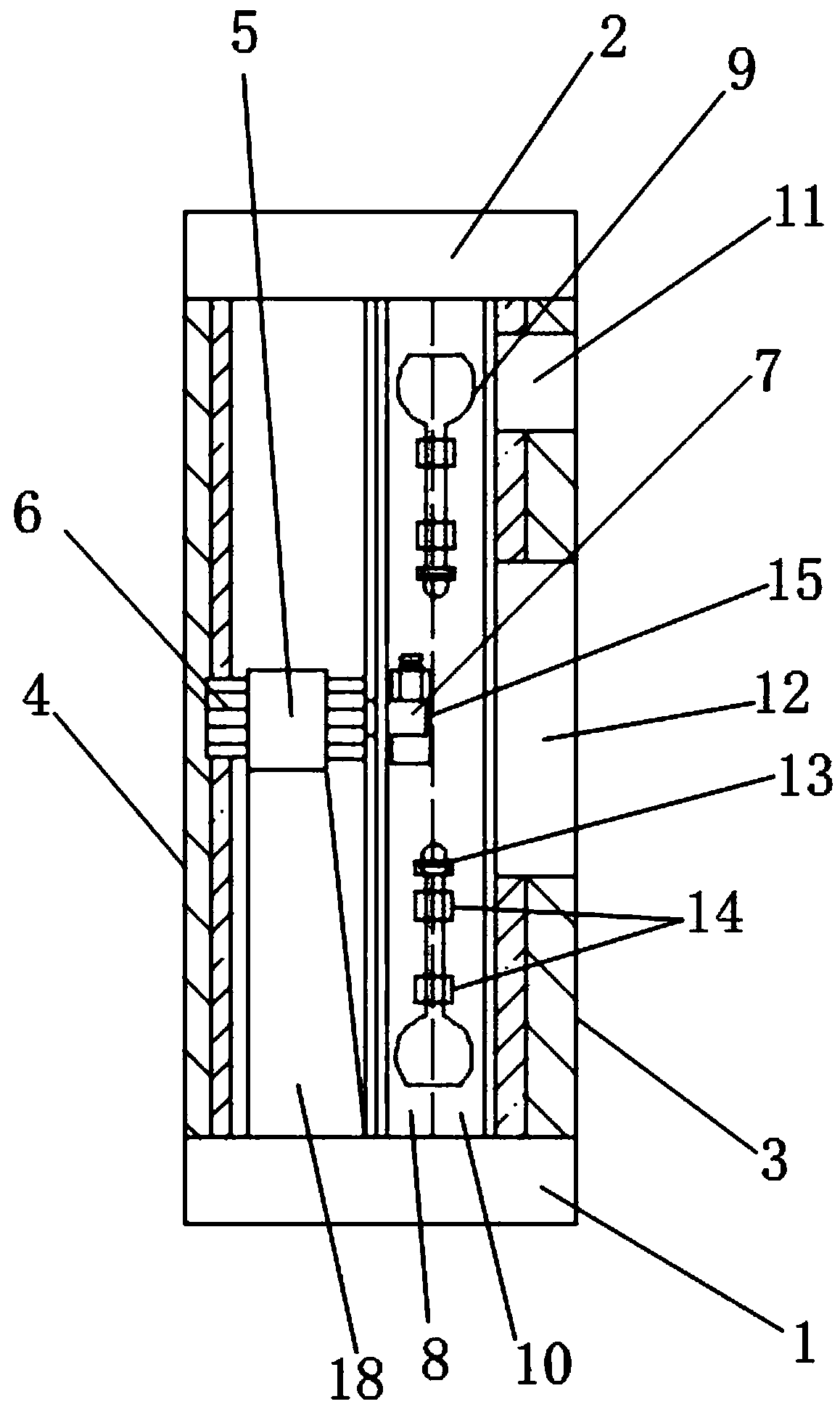

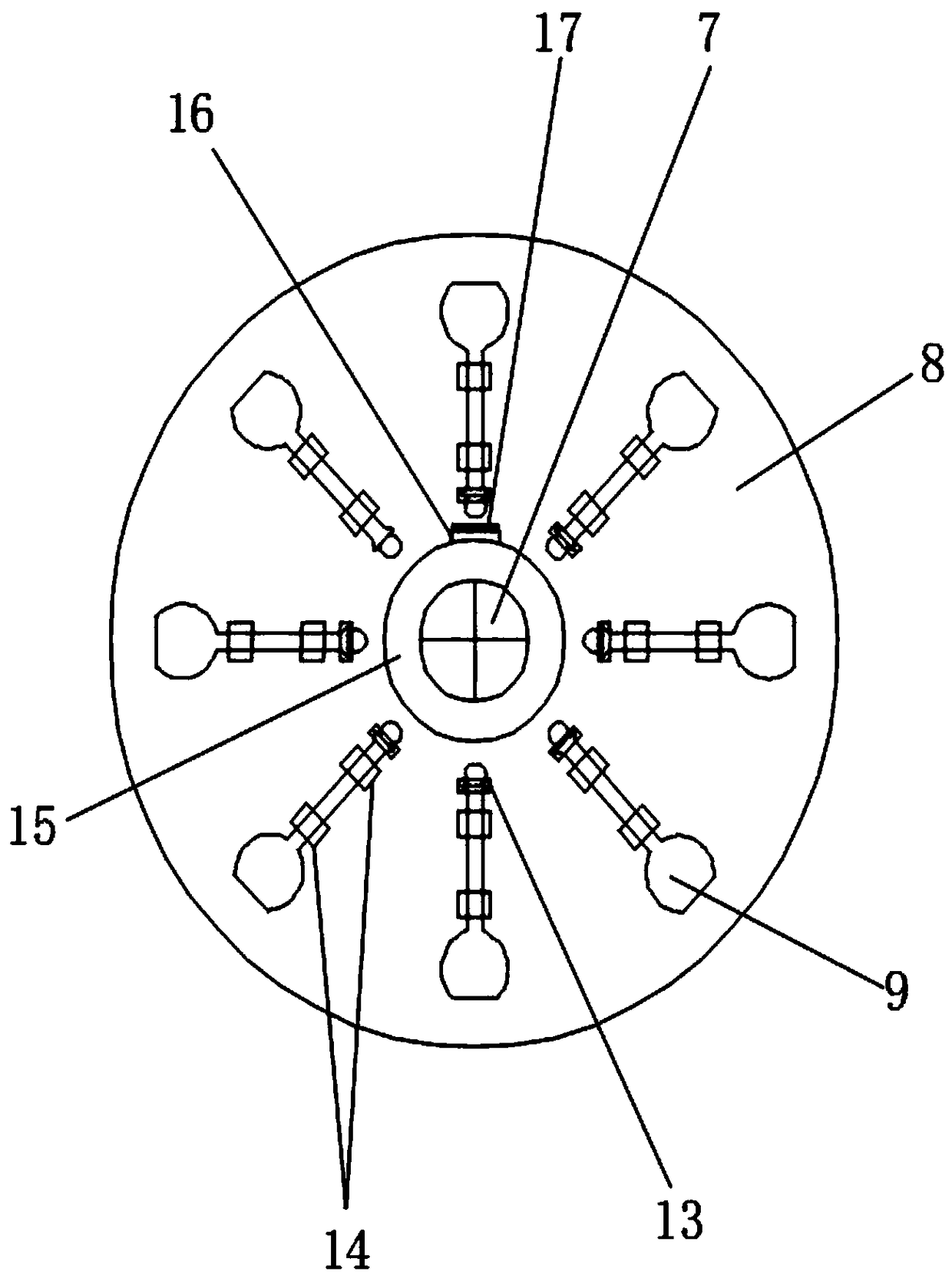

[0019] With reference to the accompanying drawings, a volumetric flask is automatically shaken after a constant volume, which includes a base 1, a machine top cover 2, a front cover 3, a rear cover 4 and a casing. The lower end of the rear cover 4 is provided with a base 1 and the upper end is provided The organic top cover 2, the rear cover 4 and the base 1 and the top cover 2 form a cavity. A motor 5 is arranged in the cavity. The motor 5 is fixed to the rear cover through a fixing base 6, and the motor 5 and the base 1 pass through a motor support frame 18 is connected, the motor output shaft 7 is provided with a splint mother board 8, a plurality of volumetric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com