Cleaning method of ceramic filter

A technology of ceramic filter and ceramic filter plate, applied in the field of filtration, can solve the problems of high depreciation rate of equipment, short production cycle, short service life of ceramic filter plate, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

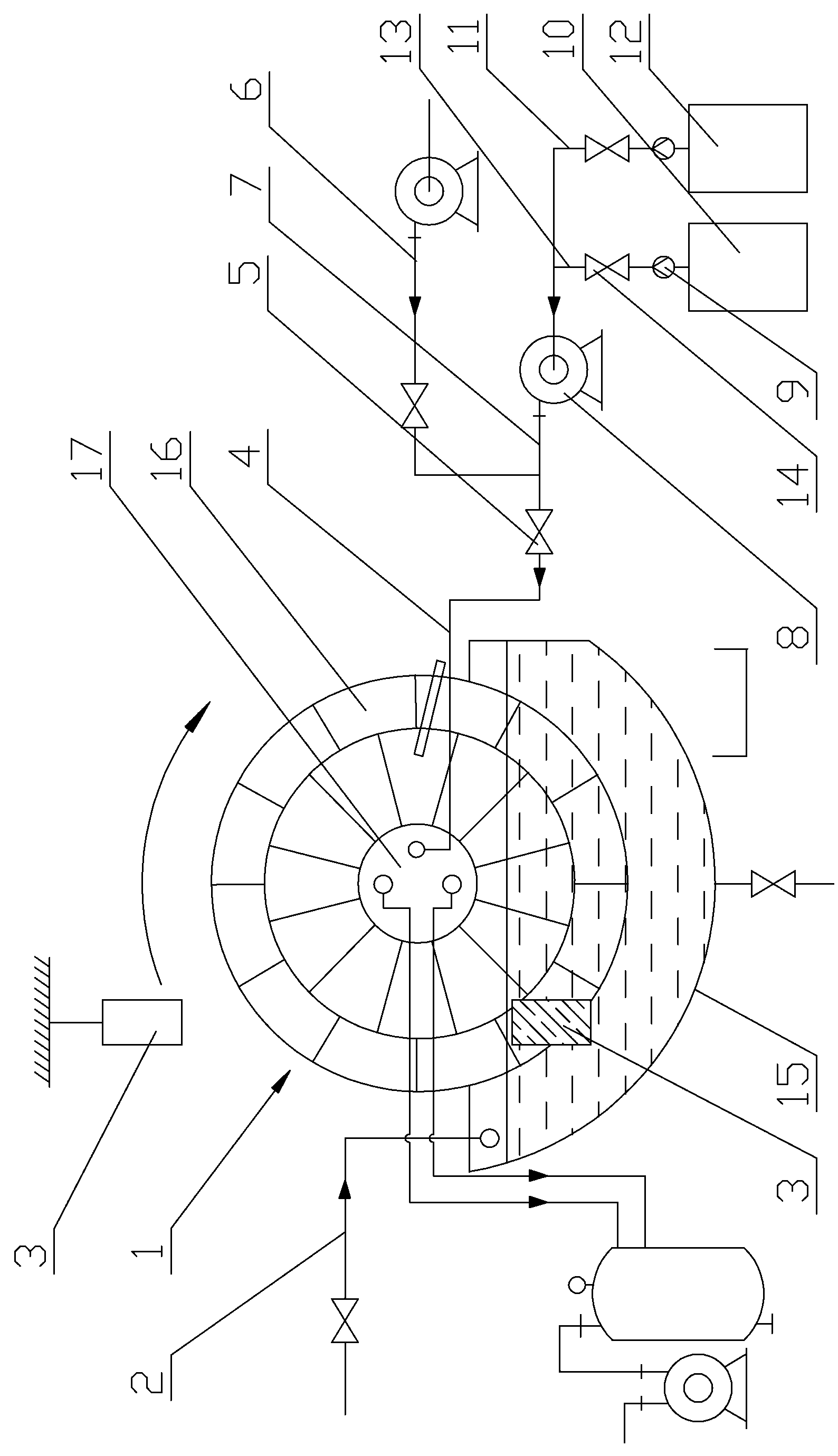

[0035] On October 9th-12th, 2014, the 1# ceramic filter was used in Chengchao Iron Mine to carry out production and cleaning tests, specifically at 8:00-10:00 am on October 9th, the ceramic filter was carried out with the method of this embodiment Cleaning, continuous production from 10:00 on October 9th to 10:00 on October 10th, shut down for cleaning from 10:00 to 12:00 on October 10th, continuous production from 12:00 on October 10th to 12:00 on October 11th Production, stop cleaning from 12:00-14:00, continuous production from 14:00 on October 11 to 14:00 on October 12, stop cleaning from 14:00-16:00, and the test is over. The specific cleaning method is as follows:

[0036] (1) Stop production, empty the ore slurry, keep the ceramic filter running without load, fill the tank body 15 with circulating production water, clean the surface of the ceramic filter plate 16 and the tank body, and empty the circulating production water;

[0037] (2) Simultaneously open the valves ...

Embodiment 2

[0045] On October 9th-12th, 2014, the 2# ceramic filter was used in Chengchao Iron Mine to carry out production and cleaning tests, specifically at 8:00-10:00 am on October 9th, the ceramic filter was carried out using the method of this embodiment Cleaning, continuous production from 10:00 on October 9th to 8:00 on October 10th, shutdown for cleaning from 8:00 to 10:00, continuous production from 10:00 on October 10th to 8:00 on October 11th, 8:00 00-10:00 shutdown for cleaning, continuous production from 10:00 on October 11 to 8:00 on October 12, shutdown for cleaning from 8:00-10:00, and the end of the test. The specific cleaning method is as follows:

[0046] (1) Stop production, empty the pulp, keep the ceramic filter running without load, fill the tank with circulating production water, clean the surface of the ceramic filter plate and the tank, and empty the circulating production water;

[0047] (2) Simultaneously open the valves on the lye supply branch pipe and the ...

Embodiment 3

[0055] On October 9th-12th, 2014, the 3# ceramic filter was used in Chengchao Iron Mine for production and cleaning tests, specifically at 8:00-10:00 am on October 9th, the ceramic filter was carried out using the method of this embodiment Cleaning, continuous production from 10:00 on October 9th to 6:00 on October 10th, shut down for cleaning from 6:00 to 8:00, continuous production from 8:00 on October 10th to 4:00 on October 11th, 4: 00-6:00 shutdown for cleaning, continuous production from 6:00 on October 11 to 2:00 on October 12, shutdown for cleaning from 2:00 to 4:00, and the test ended. The specific cleaning method is as follows:

[0056] (1) Stop production, empty the pulp, keep the ceramic filter running without load, fill the tank with circulating production water, clean the surface of the ceramic filter plate and the tank, and empty the circulating production water;

[0057] (2) Simultaneously open the valves on the lye supply branch pipe and the clean water suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com