A kind of tire rubber recycling shredder

A crusher and rubber technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as tooth structure wear, and achieve the effects of reduced tooth roller wear, high hardness, and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

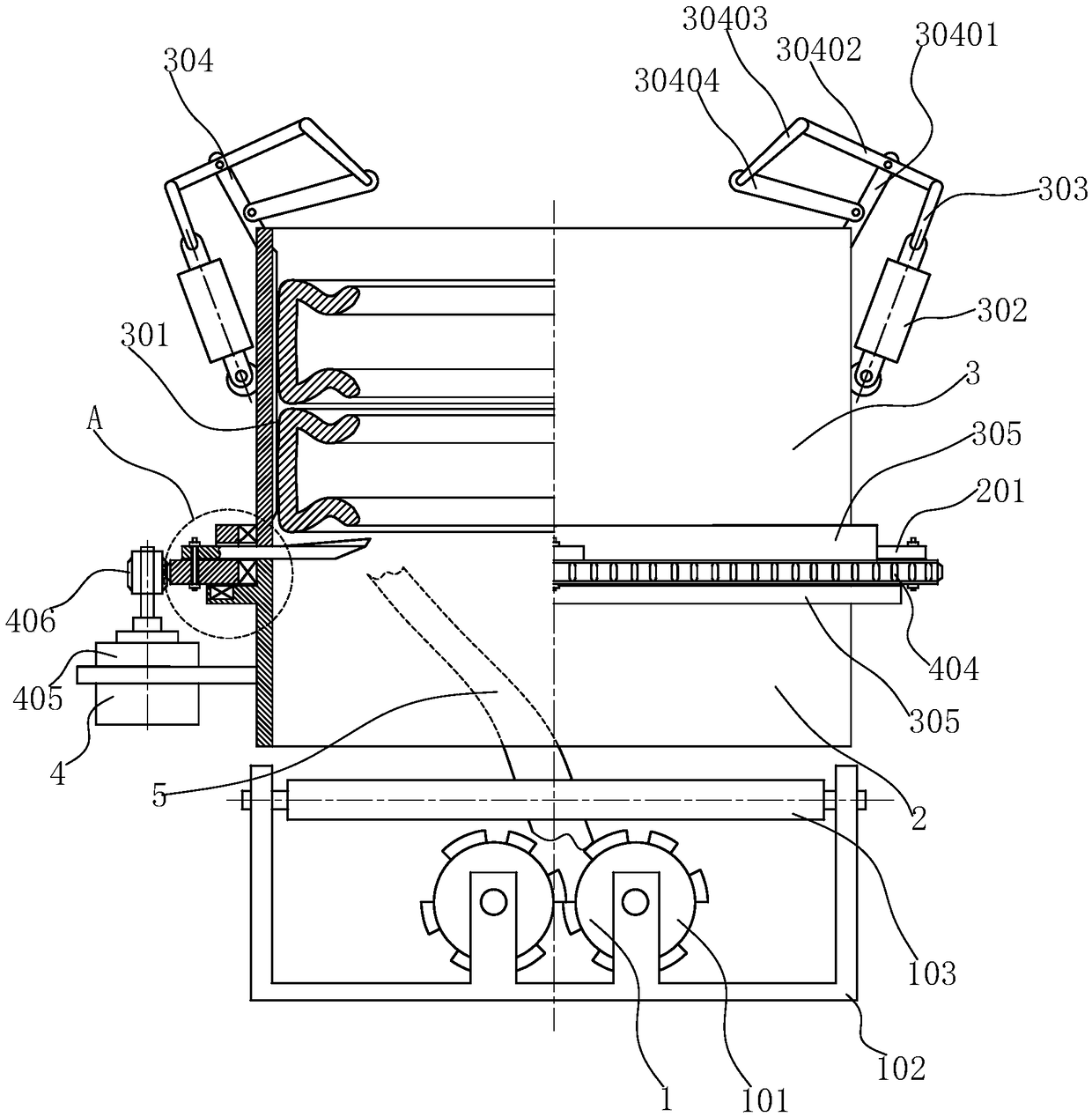

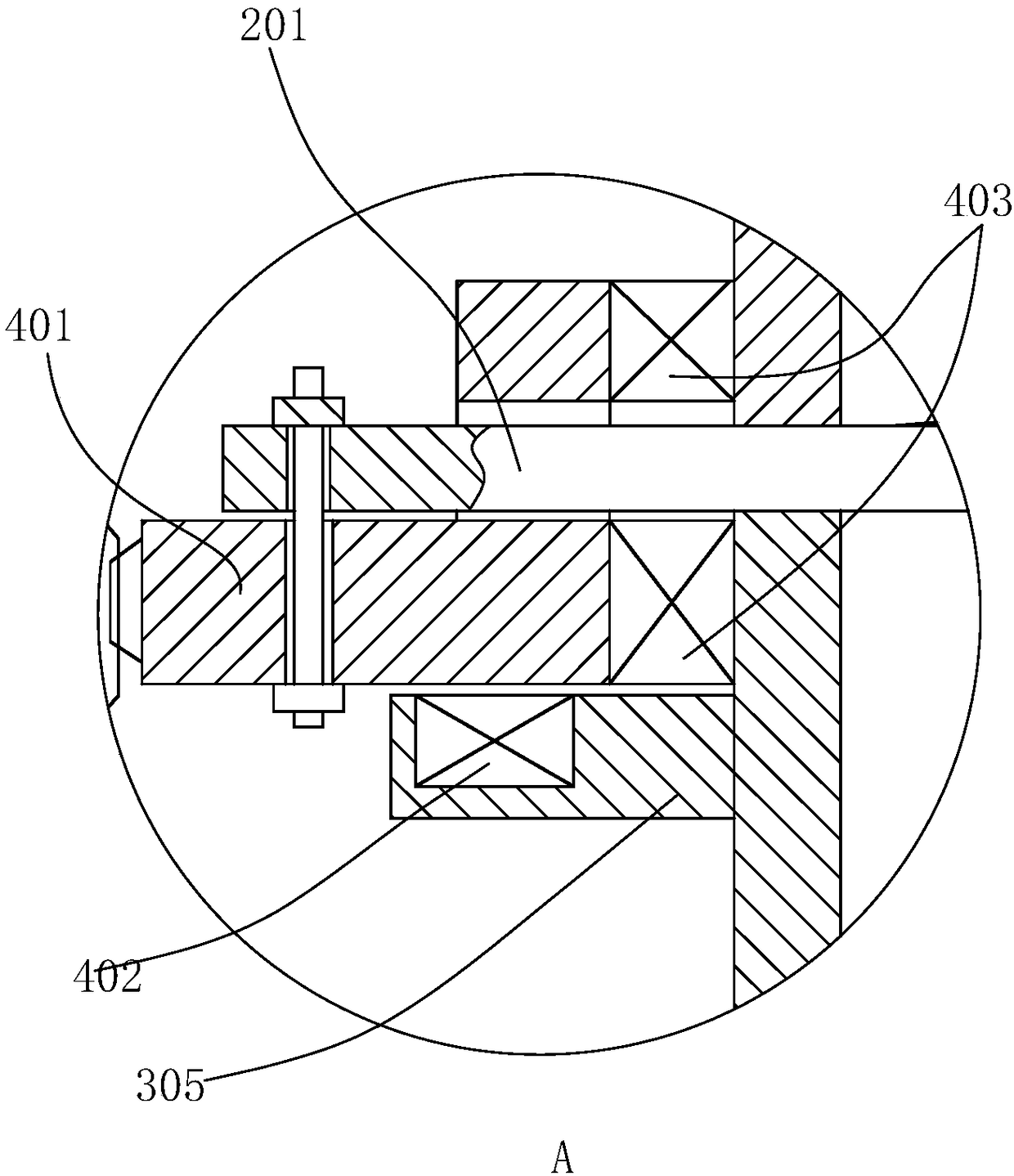

[0049] The invention is shown by way of example and is highly simplified as figure 1 , figure 2 Shown:

[0050] A tire rubber recycling shredder, including a cutting mechanism for cutting tires into flakes or granules. Due to the compact internal structure of automobile tires, there are often steel wires at the toe, so the tires have high hardness and resistance to dismantling. Large, in the prior art, the tire shredders use the blade structure to tear the tire into pieces. Due to the high extrusion strength, the tension between the blade structures used to crush the tire is large, and it is often necessary to add buffer or reduce The shock structure leads to complex structure and bulky equipment, and even so, the tire still has a strong reaction force and friction to the blade structure, causing the blade structure to be quickly worn. If the crushing is carried out according to the above-mentioned method in the prior art, No matter what kind of blade structure, it is diffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com