Composite diaphragm of pulp pump and process for producing composite diaphragm

A composite diaphragm and pulp pump technology, applied in the direction of diaphragms, mechanical equipment, etc., can solve problems such as difficulty in ensuring reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

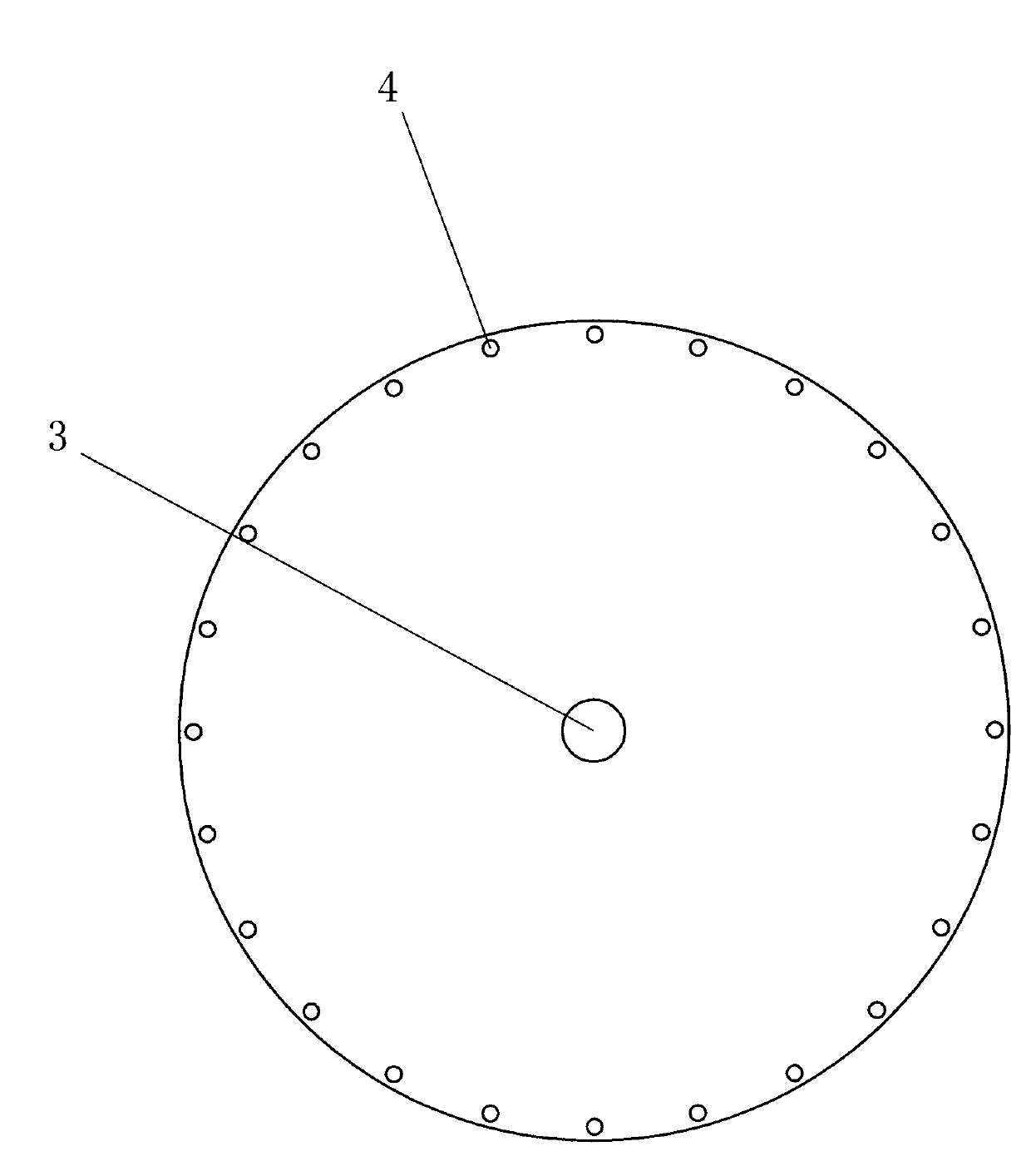

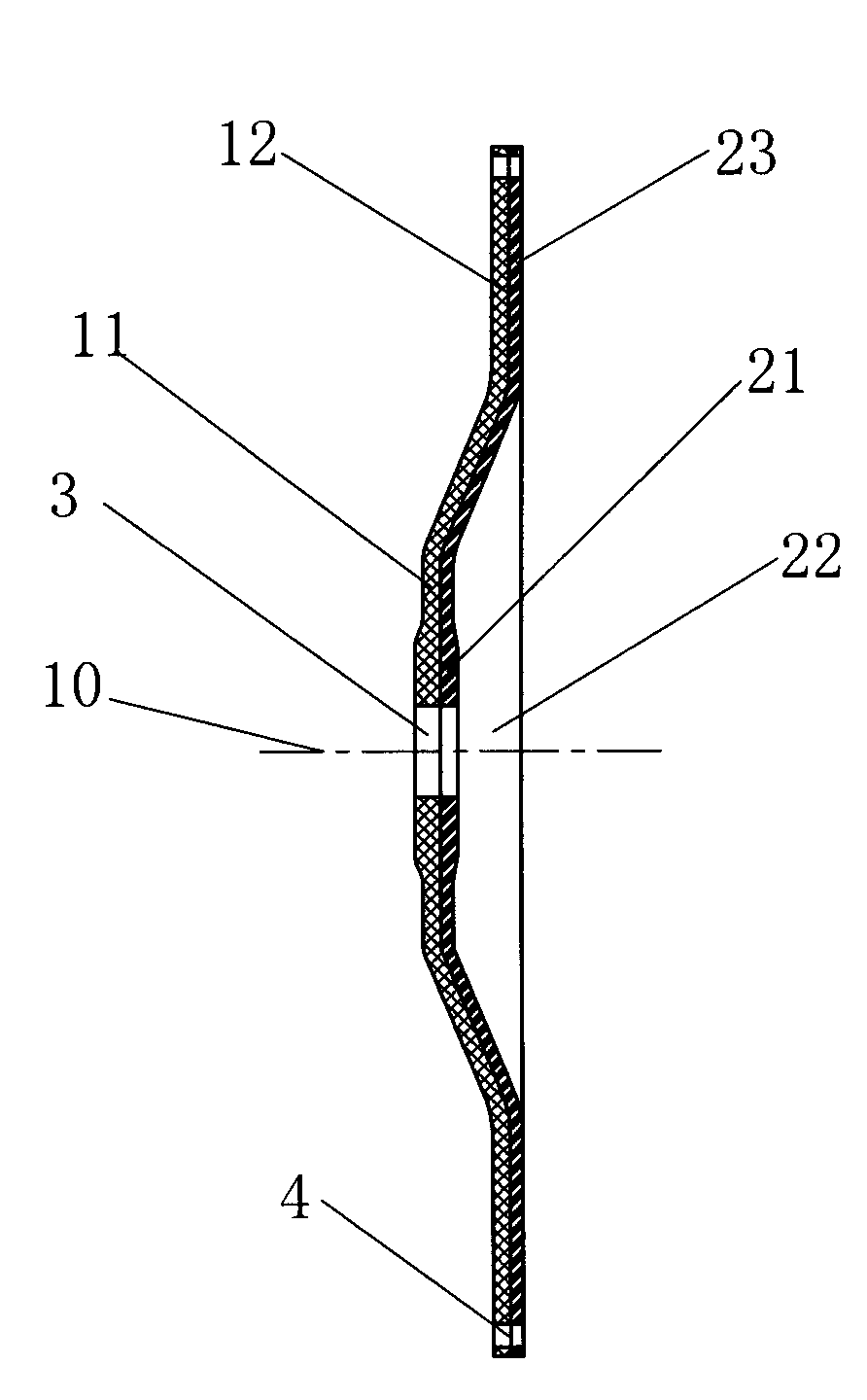

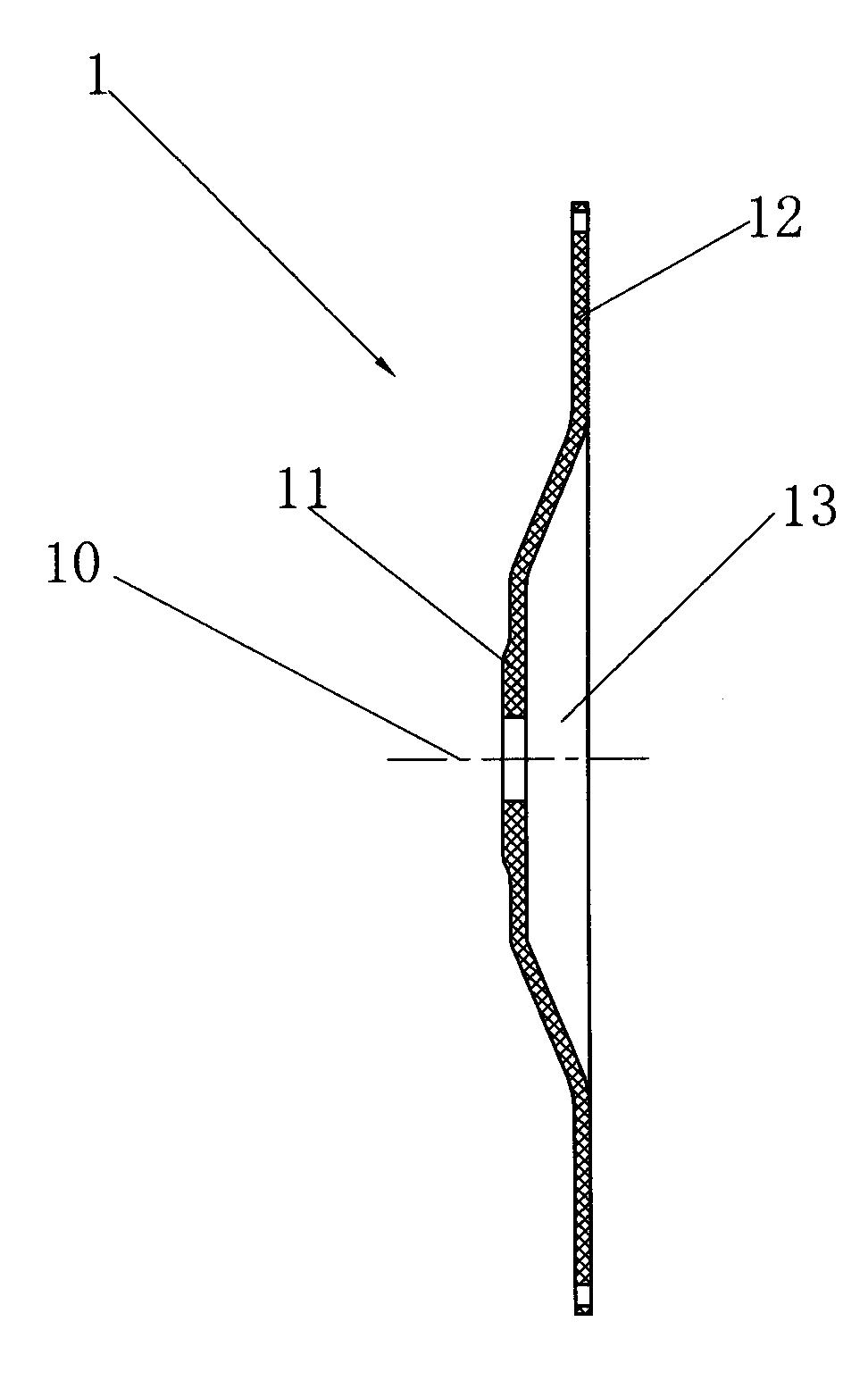

[0021] Such as Figure 1-4 As shown, the specific embodiment of the present invention is a composite diaphragm of a slurry pump, which includes a rubber layer 1 and a polyurethane layer 2. The rubber layer 1 has a circular structure and includes axial protrusions along the central axis 10 of the composite diaphragm. The raised part 11 with an isosceles trapezoidal structure in cross section and the flange 12 extending along the periphery of the raised part 11, wherein a corresponding recessed part 13 is formed on the other side of the raised part 11 relative to the rubber layer 1, so The polyurethane layer 2 is adapted to the shape and structure of the rubber layer 1, by Figure 4 It can be seen that the polyurethane layer has a first protruding portion 21 and a corresponding first concave portion 22 and a first flange 23 extending along the periphery of the first protruding portion 21, and the first protruding portion 21 of the polyurethane layer 2 Compatible with the recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com