Ceramic filter cleaning system

A technology of ceramic filter and cleaning system, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc. It can solve problems such as excessive corrosion of equipment, acid leakage, and excessive water content of mineral powder, so as to improve processing capacity and reduce Equipment corrosion and the effect of reducing the water content of mineral powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

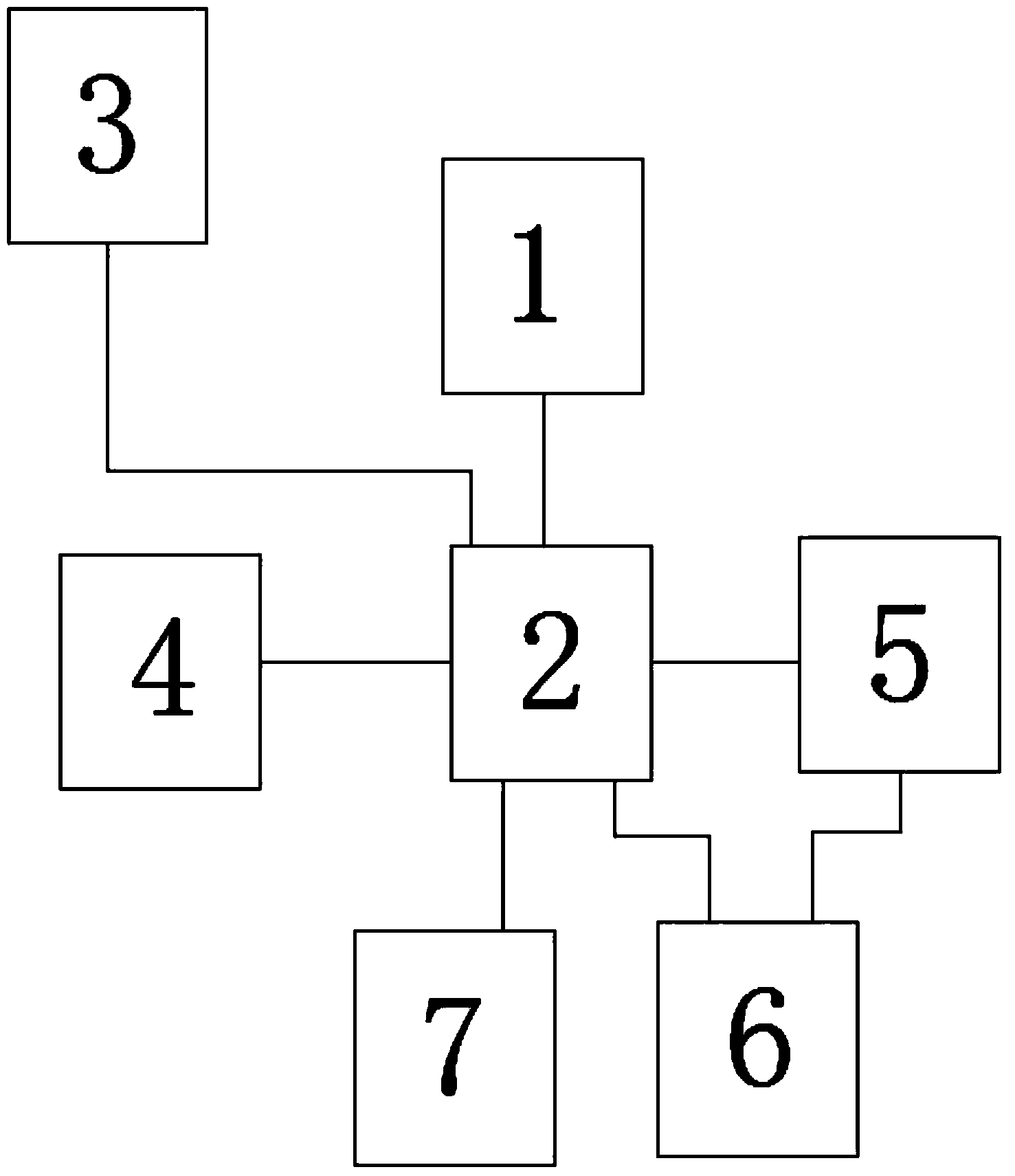

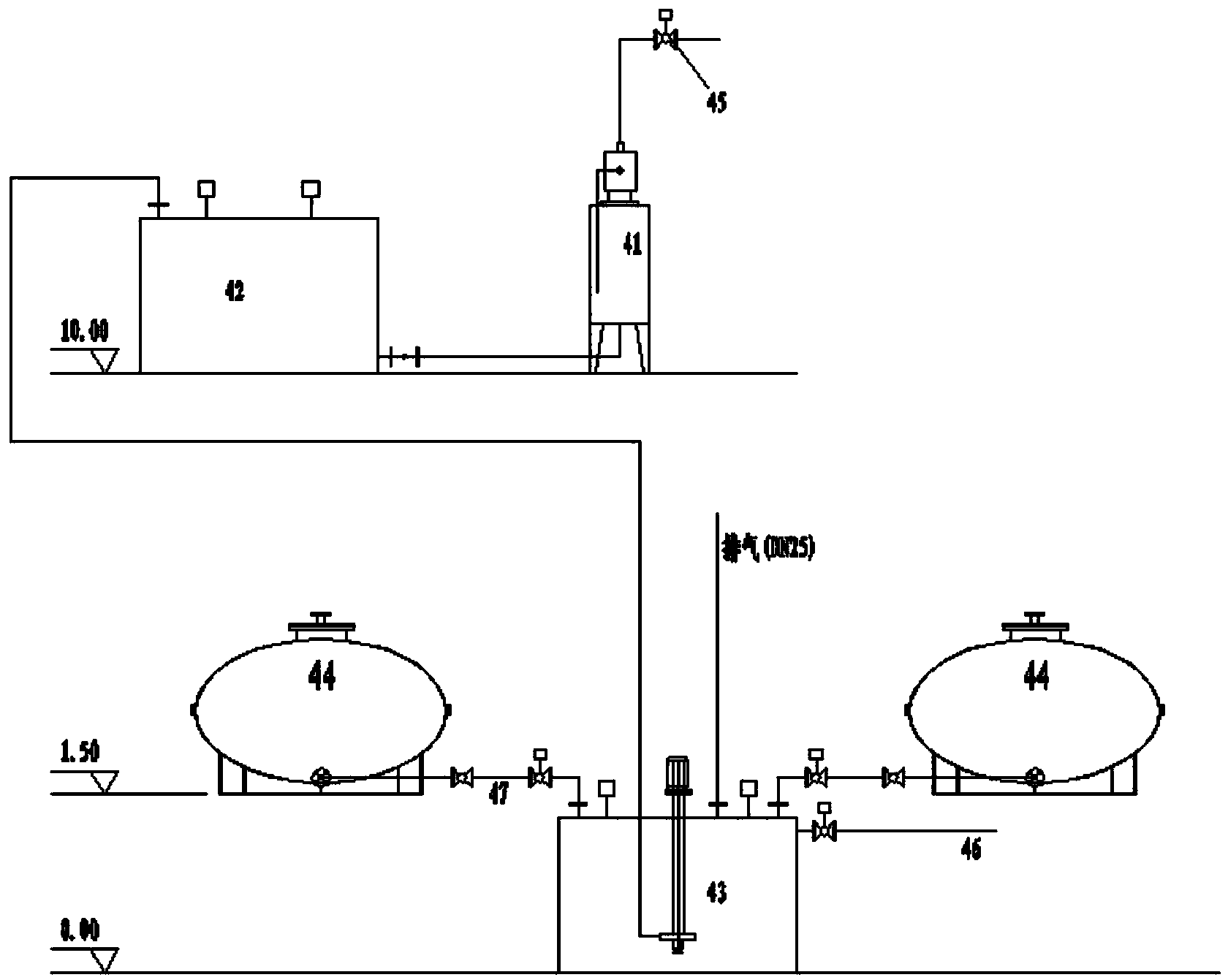

[0020] Such as figure 1 A cleaning system for a ceramic filter is shown, including a mineral separation box 1, a ceramic filter 2, a high-level water tank 3, and an acid adjustment system 4; the pipeline below the mineral-separation box 1 is connected to a ceramic filter 2; the high-level water tank 3 It is arranged above the ceramic filter 2 and connected to the ceramic filter 2 in pipeline; the acid adjustment system 4 is arranged at a position not higher than the ceramic filter 2, and the acid adjustment system 4 is connected to the ceramic filter 2 in pipeline.

[0021] The inlet end of the high-level water tank 3 is provided with a ceramic membrane filter. Since the ceramic membrane filter does not need to replace the filter material, there is no need to stop and backwash, and the operating cost is reduced, thereby ensuring the filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com