Method and device for cleaning ceramic filter

A ceramic filter and cleaning device technology, applied in the filter field, can solve problems such as waste of chemicals and water resources, impact on equipment production capacity, environmental pollution, etc., and achieve the effects of reducing consumption, increasing production capacity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

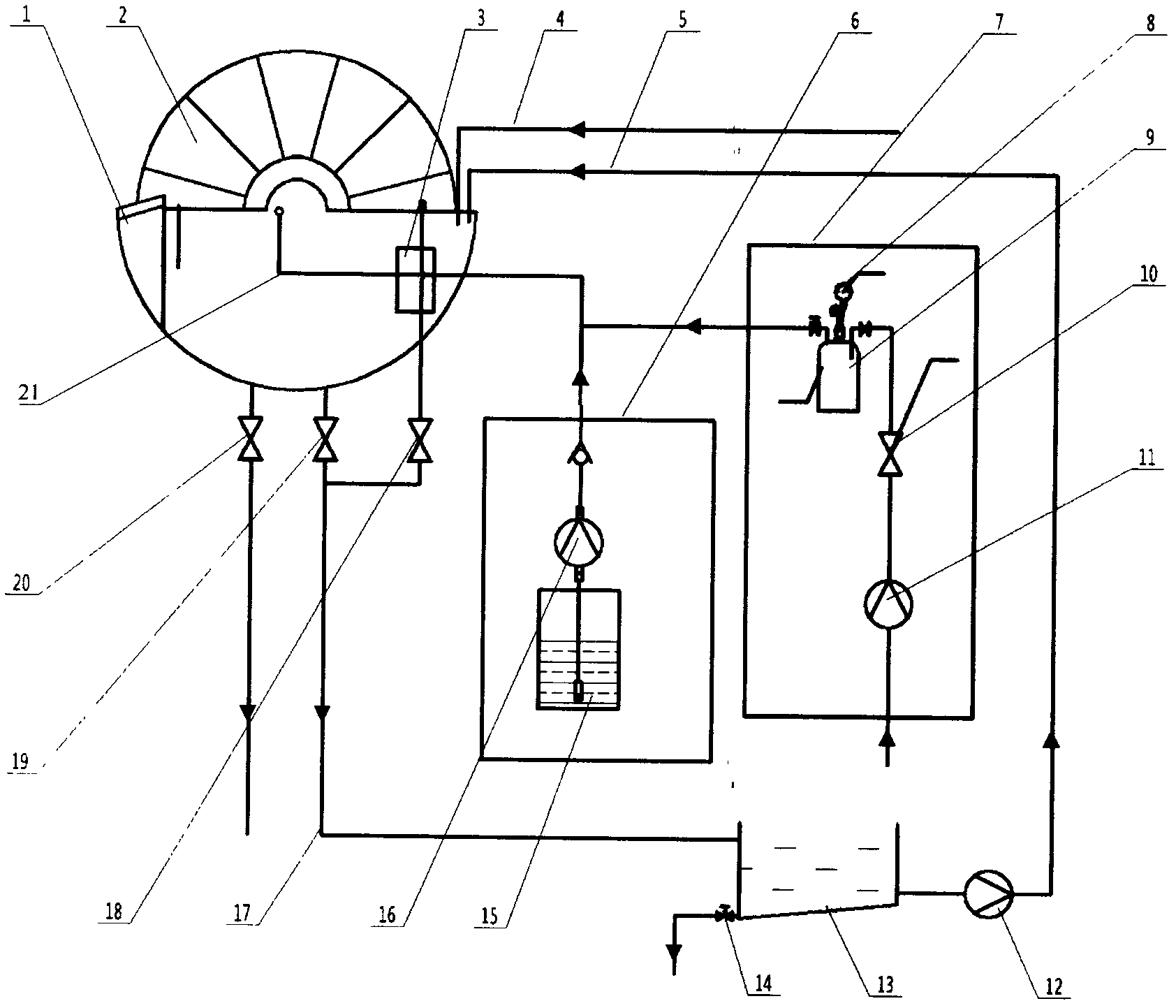

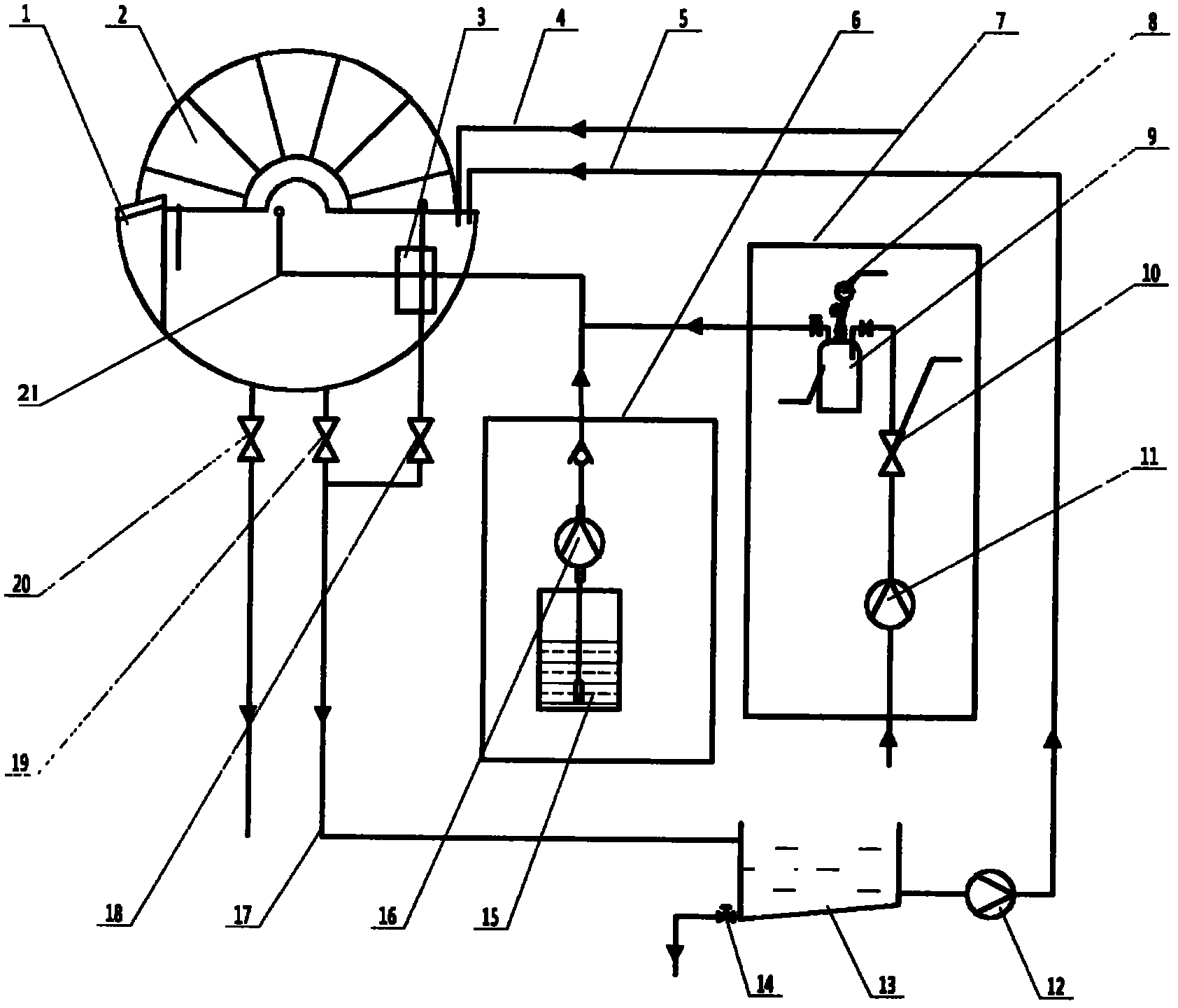

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, and the following embodiments are given.

[0021] It consists of a dispensing device 6, a backwash system 7, and a lotion recycling system composed of a lotion pool 13, a circulation pump 12, and a lotion water pipeline 5.

[0022] Initial cleaning of the ceramic filter: After the filter is stopped, rinse the material on the tank body 1 and the ceramic plate 2, and discharge it through the discharge valve; add cleaning water through the cleaning water pipeline 4 to submerge the ceramic filter in the tank body 1 Plate 2, start the ultrasonic vibrator box 3 for ultrasonic cleaning; turn on the backwash pump 11, send clean water through the backwash valve 10 and filter 9 into the interior of the ceramic plate for backwashing from the inside to the outside, and at the same time, the metering pump 16 pumps the storage tank 15 The concentrated chemical cleaning agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com