Device and method for preventing feeding valve of ceramic filter from being blocked

A ceramic filter and feed valve technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of easy blockage of pipelines, time-consuming and laborious, and blocked pipelines affect normal production, etc., to improve production efficiency , save settings and use, optimize the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

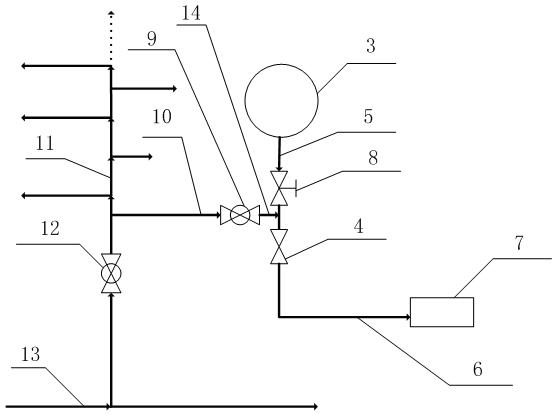

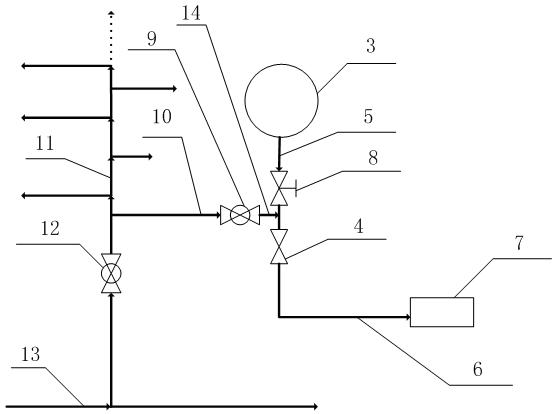

[0027] Combine below figure 2 , the present invention is further described:

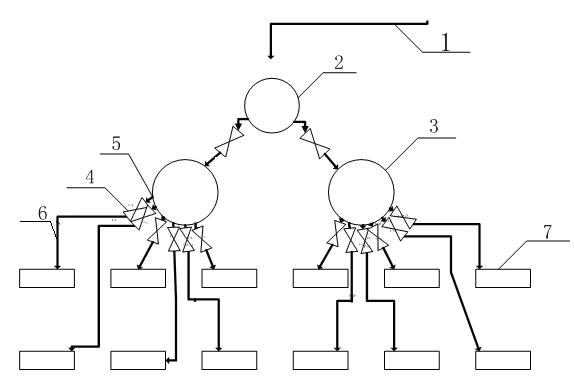

[0028] A device for preventing the feed valve of a ceramic filter from being clogged, comprising a main pulp pipeline 1, a distribution tank 2, a mixing tank 3, a feed valve 4 and a ceramic filter 7, the pulp from the main pulp pipeline 1 enters the distribution tank 2, The distribution barrel 2 distributes the ore slurry to one or more mixing barrels 3, each mixing barrel 3 is connected to each ceramic filter 7 through a pipeline, and a feed valve 4 is set on the pipeline, and the feed valve 4 divides the pipeline into The feed valve front pipe 5 and the feed valve rear pipe 6, the mineral powder accumulated in the feed valve 4, the feed valve front pipe 5 and the feed valve rear pipe 6 are flushed and dredged through the recoil device.

[0029] Specifically, the recoil device includes a manual valve 8, a flushing ball valve 9 and a recoil pipeline 14. The manual valve 8 is arranged on the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com