Ceramic filter

A ceramic filter and filter membrane technology, which is applied in the direction of filtration separation, dispersed particle filtration, chemical instruments and methods, etc., can solve problems such as filter membrane cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

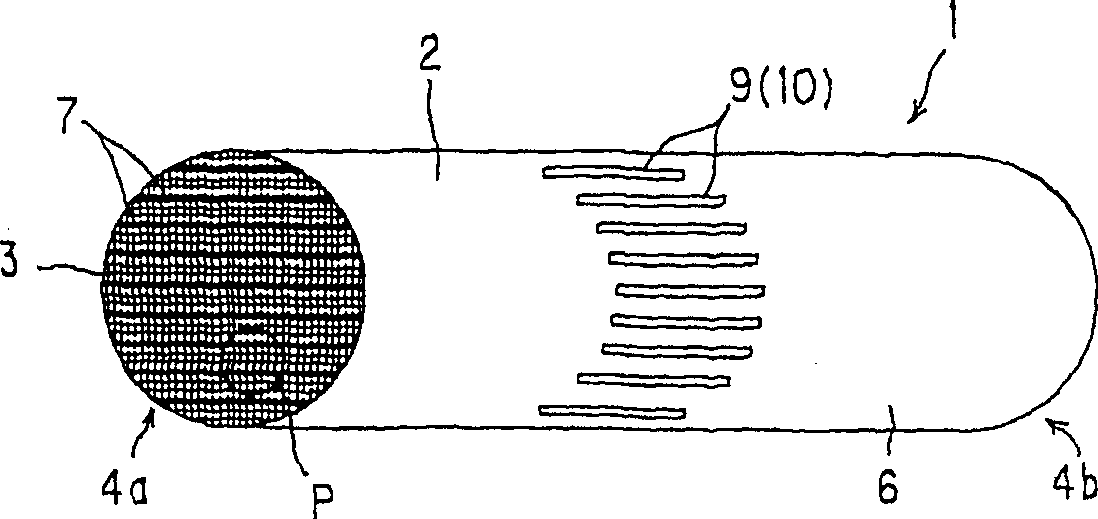

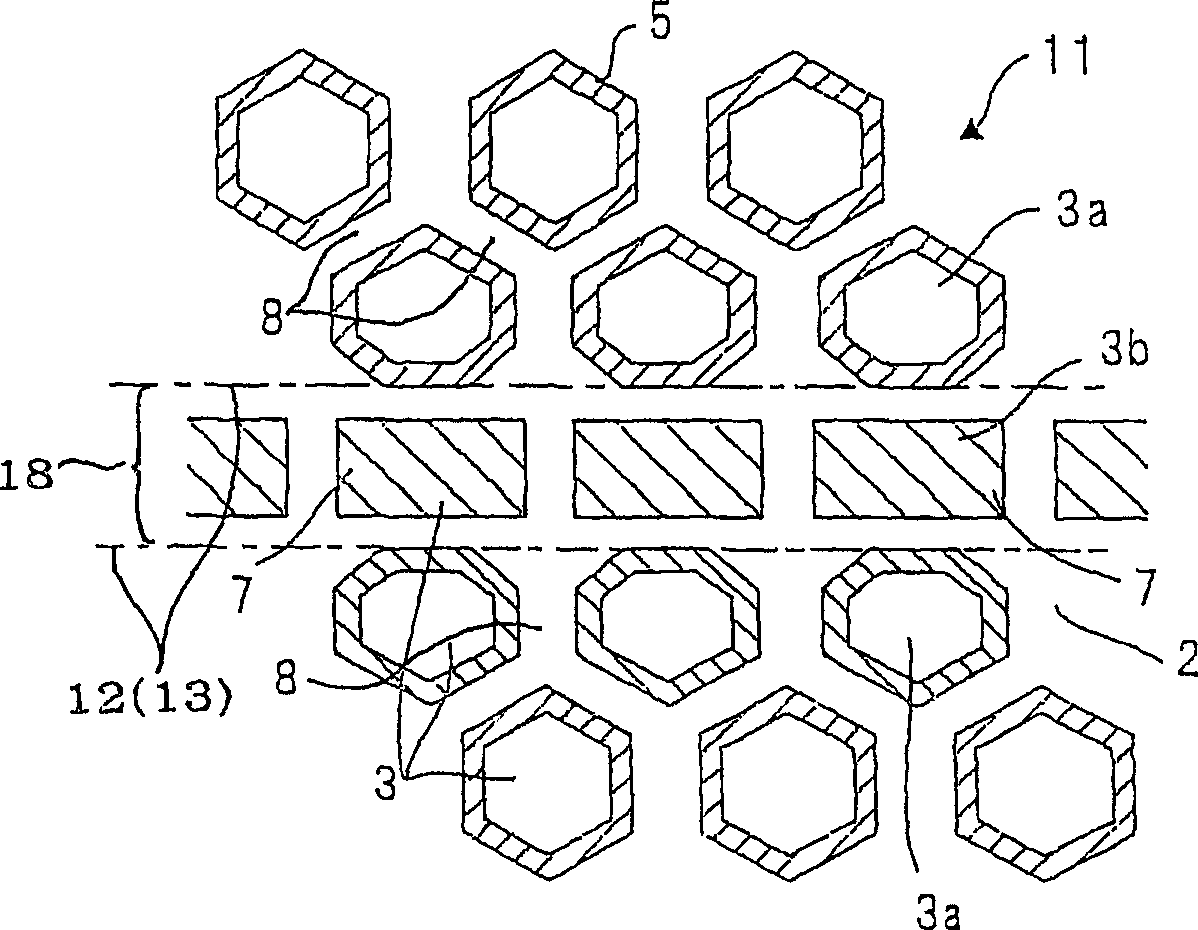

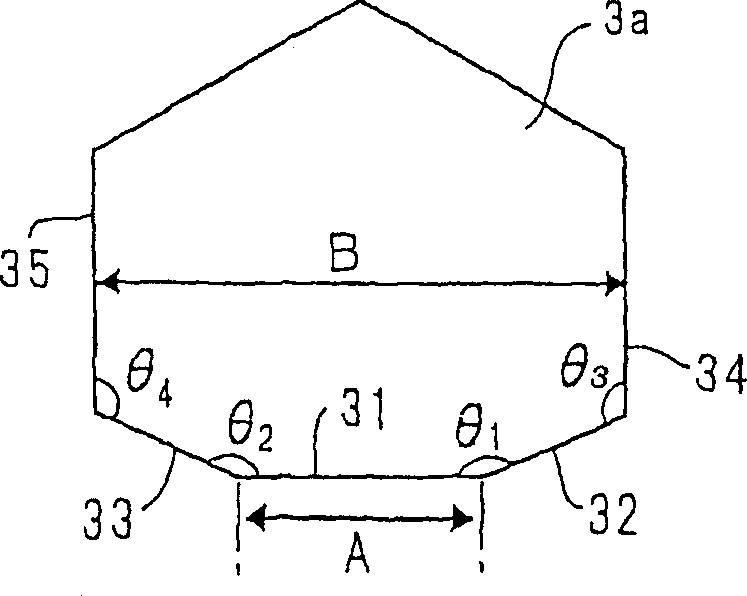

[0047] As the aggregate, use screened alumina with a particle diameter of 30-100 μm, add feldspar with a particle diameter of 0.5-5 μm as a sintering aid, water as a dispersion medium, and methyl cellulose as an organic binder. The kneaded clay was extruded to obtain a honeycomb-shaped molded body having a plurality of main channels. After the molded body is dried, it is cut into a predetermined length perpendicular to the direction of the flow path, and is sintered to obtain 61 columns with an inner diameter of 180mm, a flow path with an inner diameter of 2.5mm, and a length of 1000mm. One row has a maximum of 53 main flow rows. , The whole main channel is about 2200 honeycomb-shaped porous bodies. In addition, the porosity of the porous body measured by the JIS dipping method was 40%, and the average pore diameter of the porous body measured by the mercury porosimetry was 20 μm.

[0048] Next, six rows of enlarged slit-shaped auxiliary flow paths were formed in the center o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com