Automatic liquid discharging device for vacuum ceramic filter

A technology of automatic liquid drainage and vacuum ceramics, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of complex operation and low drainage efficiency, achieve simple operation, high drainage efficiency, and improve the overall output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

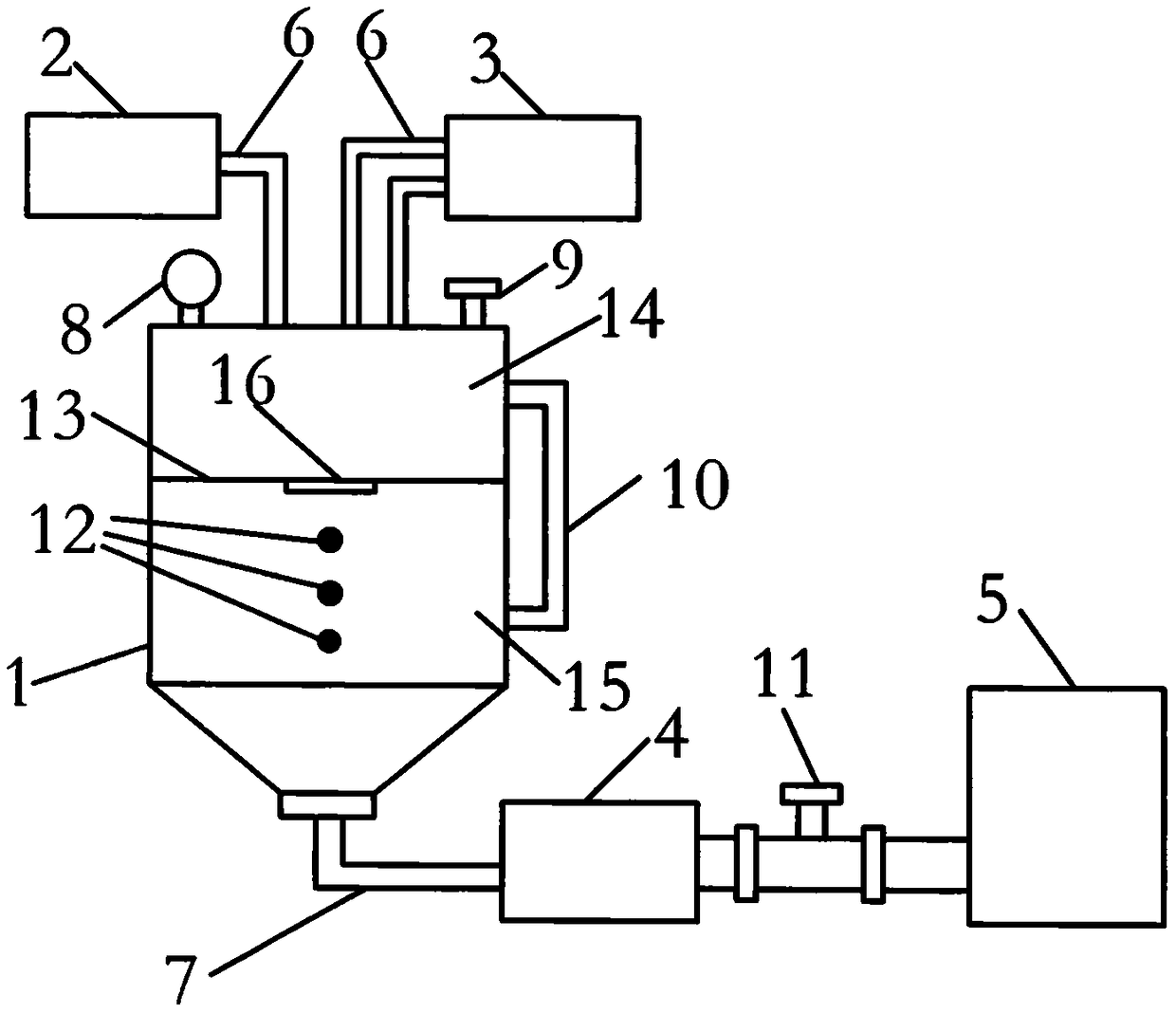

[0011] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 As shown, it is an automatic liquid draining device for a vacuum ceramic filter provided in the embodiment of the present invention, including: one end of the top of the vacuum tank 1 is connected to the vacuum pump 2 through a vacuum tube 6, and the other end is connected to the ceramic filter liquid distributor 3 through the vacuum tube 6 connection; the bottom of the vacuum tank 1 is connected to the drain pump 4 through the wire hose 7, and the drain pump 4 is connected to the liquid storage barrel 5 through the pneumatic valve 11; Three liquid level sensors 12, the side of the vacuum tank 1 is provided with a liquid level tube 10 for measuring the water level, the vacuum tank 1 is divided into an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com