On-line gas cleaning method for ceramic filter

A ceramic filter and compressed gas technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of unstable pressure and water volume, poor effect, large pressure loss, etc., and achieve improved work efficiency and cleaning effect Visible, small pressure fluctuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

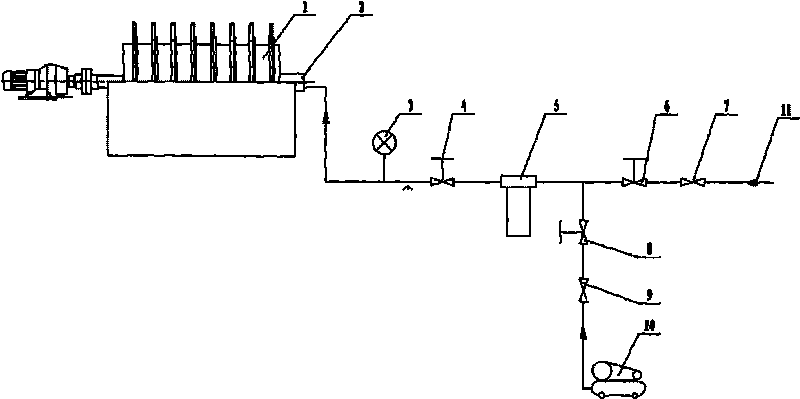

[0011] Such as figure 2 As shown, the water backwashing device of the cleaning system of the ceramic filter consists of water pressure regulating hand valves 4 and 6, a filter 5, a pneumatic ball valve 7, a pressure gauge 3, and stainless steel pipe fittings connecting the above components in series to the distribution valve 2 Composed, the air compressor 10 for the air source of the present invention is connected to the pipeline of the water backwashing device through the pneumatic ball valve 9, the air pressure regulating hand valve 8, the water pressure regulating hand valve 6 and the filter 5.

[0012] When the ceramic filter is running normally, close the pneumatic ball valve 7 for cleaning water control, open the air compressor 10 and the pneumatic ball valve 9 for air source control, and adjust the air pressure adjustment hand valve 8 by observing the pressure gauge 3 to obtain the best performance. The pressure and gas volume of the gas used to clean and dredge the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com