Ceramic filter-element dust collector

A technology of ceramic filter elements and dust collectors, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. Long service life and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

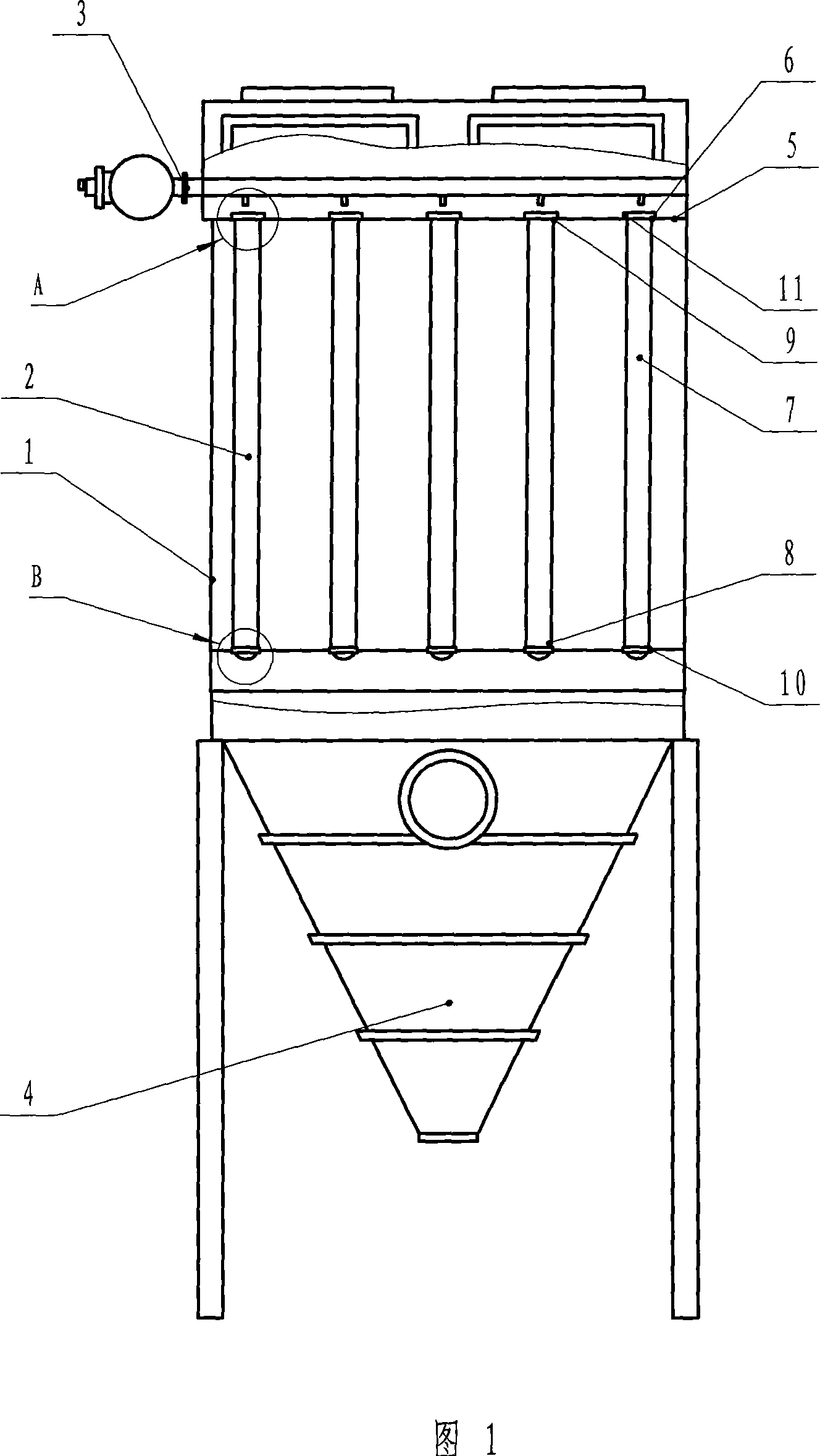

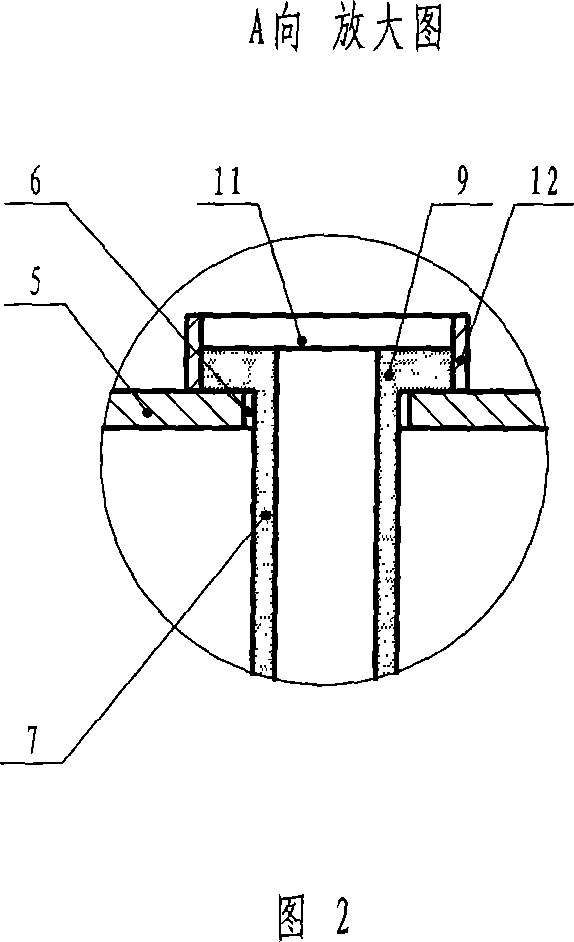

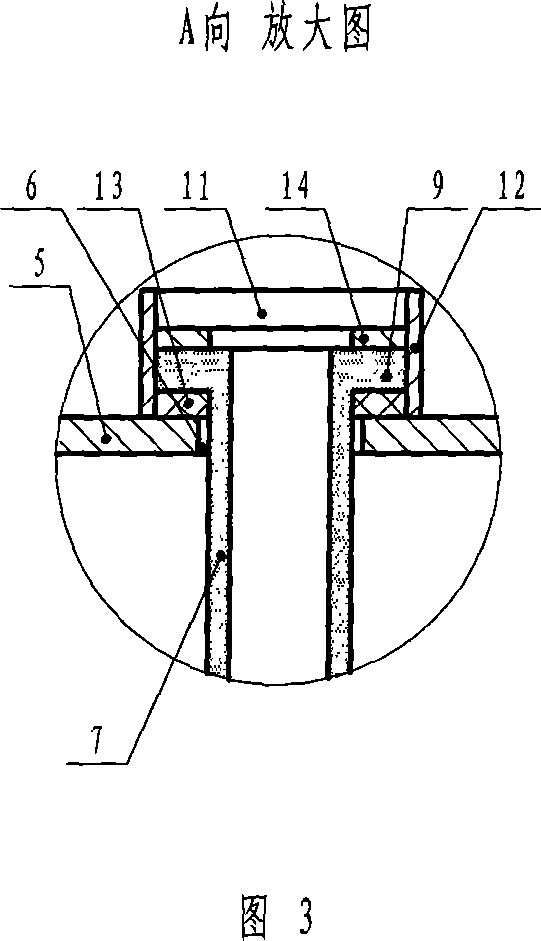

[0021] Fig. 1~Fig. 4 is the structure schematic diagram and partial schematic diagram of the ceramic filter element dust collector of the present invention, wherein in Fig. 1, the ceramic filter element dust collector of the present invention mainly comprises: housing 1, ceramic filtering device 2, pulse blowback system 3 and Cleaning system 4, wherein the structure of the ceramic filter device 2 is: the flower plate 5 is fixed on the inner wall of the housing 1, the flower plate 5 is provided with a small hole 6, and the lower end 8 of the ceramic filter element 7 extends from the flower plate hole 6 Into the housing 1, the lower end 8 is fixed with the housing 1 through the lower fixing device 10, the upper end 9 of the ceramic filter element 7 is connected with the flower plate 5, and the upper end 9 is fixed with the flower plate 5 through the upper fixing device 11 .

[0022] Fig. 2 is a structural schematic diagram of a partial view A of a ceramic filter element dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com