On-line washing method of ceramic filter and apparatus therefor

A ceramic filter and cleaning device technology, applied in the directions of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing operating costs, high costs, and impact on filtration output, and achieve the expansion of the scope of use and the improvement of cleaning effects. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

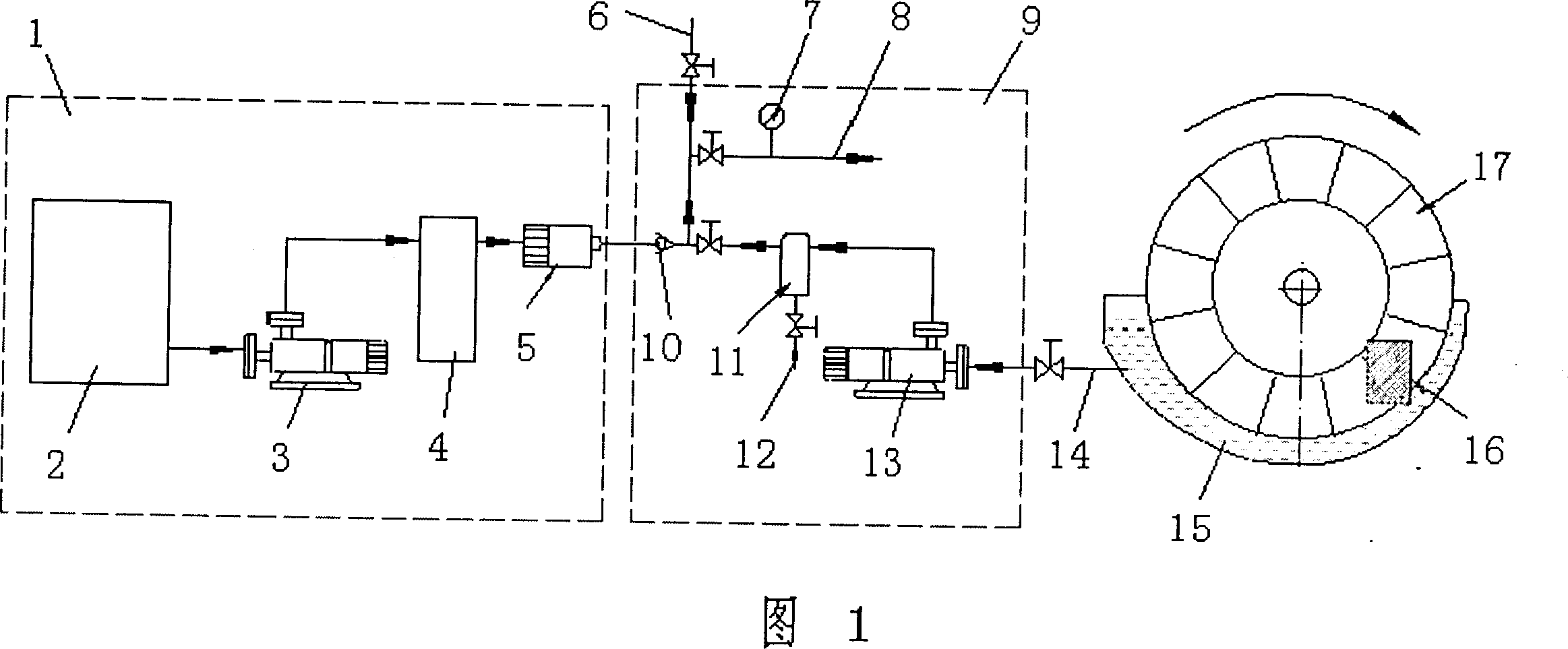

[0024] As shown in Figure 1, the online cleaning device of the present invention includes two parts: a cleaning liquid distribution device 1 and a cleaning liquid circulation cleaning device 9, and the cleaning liquid distribution device 1 includes a storage tank 2, a pump 3, an acid distribution tank 4 and a metering pump 5 . The cleaning liquid circulation cleaning device 9 includes a liquid inlet pipe 14 , a circulation pump 13 , a filter 11 , and a liquid discharge pipe 8 . The cleaning process is as follows:

[0025] First the ceramic filter machine of normal operation is parked, put slurry, remove the silt in the ceramic filter plate 17 on the filter machine, the rotor, the tank body 15, and rinse with clean water. Use the pump 3 to pump the concentrated cleaning agent without nitric acid from the storage tank 2 to the acid distribution tank. A level gauge is provided in the acid distribution tank to measure the amount of cleaning agent required for one cleaning. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com