Yttria foamed ceramic filter and preparation method thereof

A technology of foam ceramics and filters, applied in chemical instruments and methods, ceramic products, filtration and separation, etc., can solve problems such as difficult to meet the requirements of filtration, achieve good filtration ability, good effect, and avoid broken effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

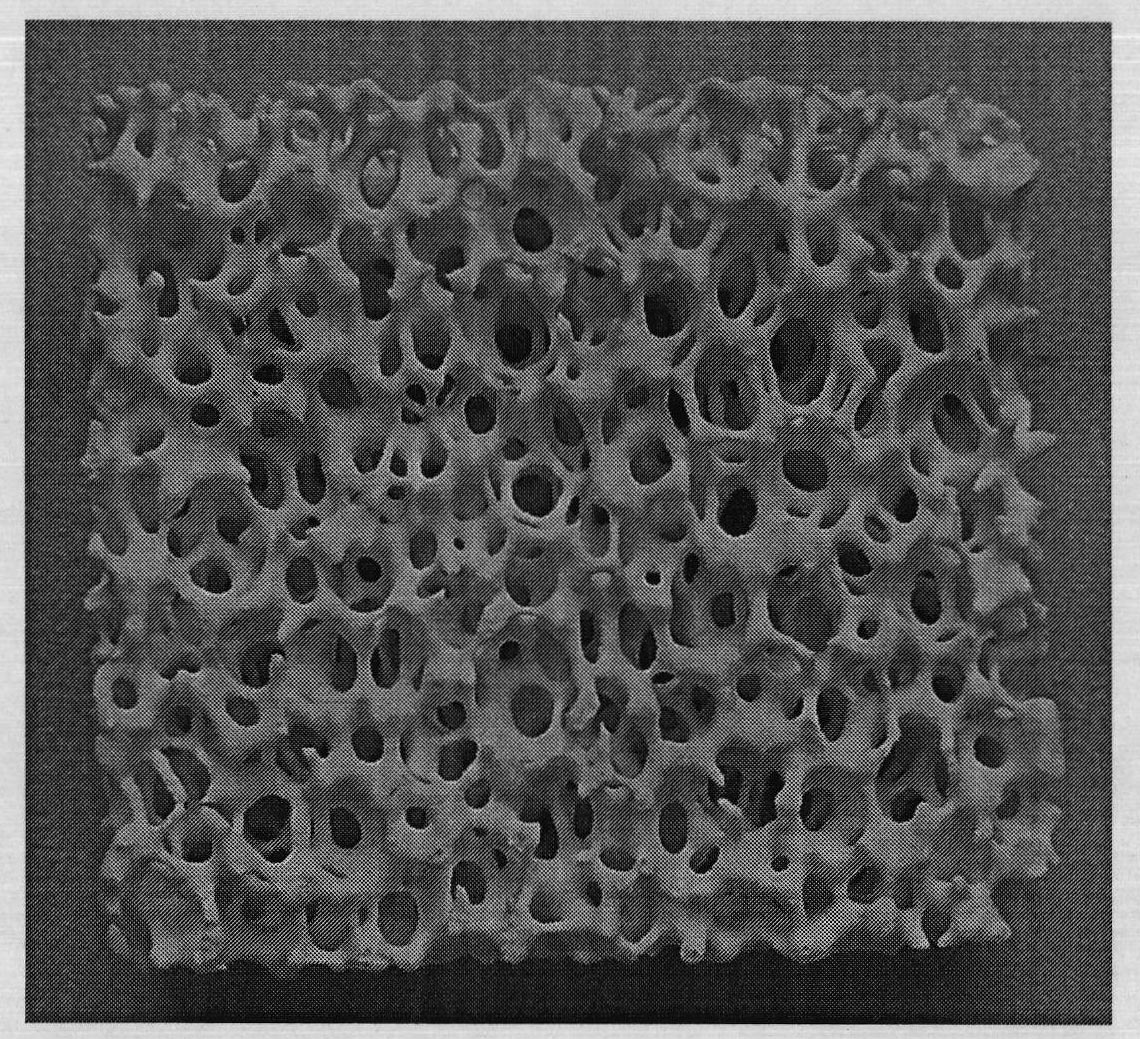

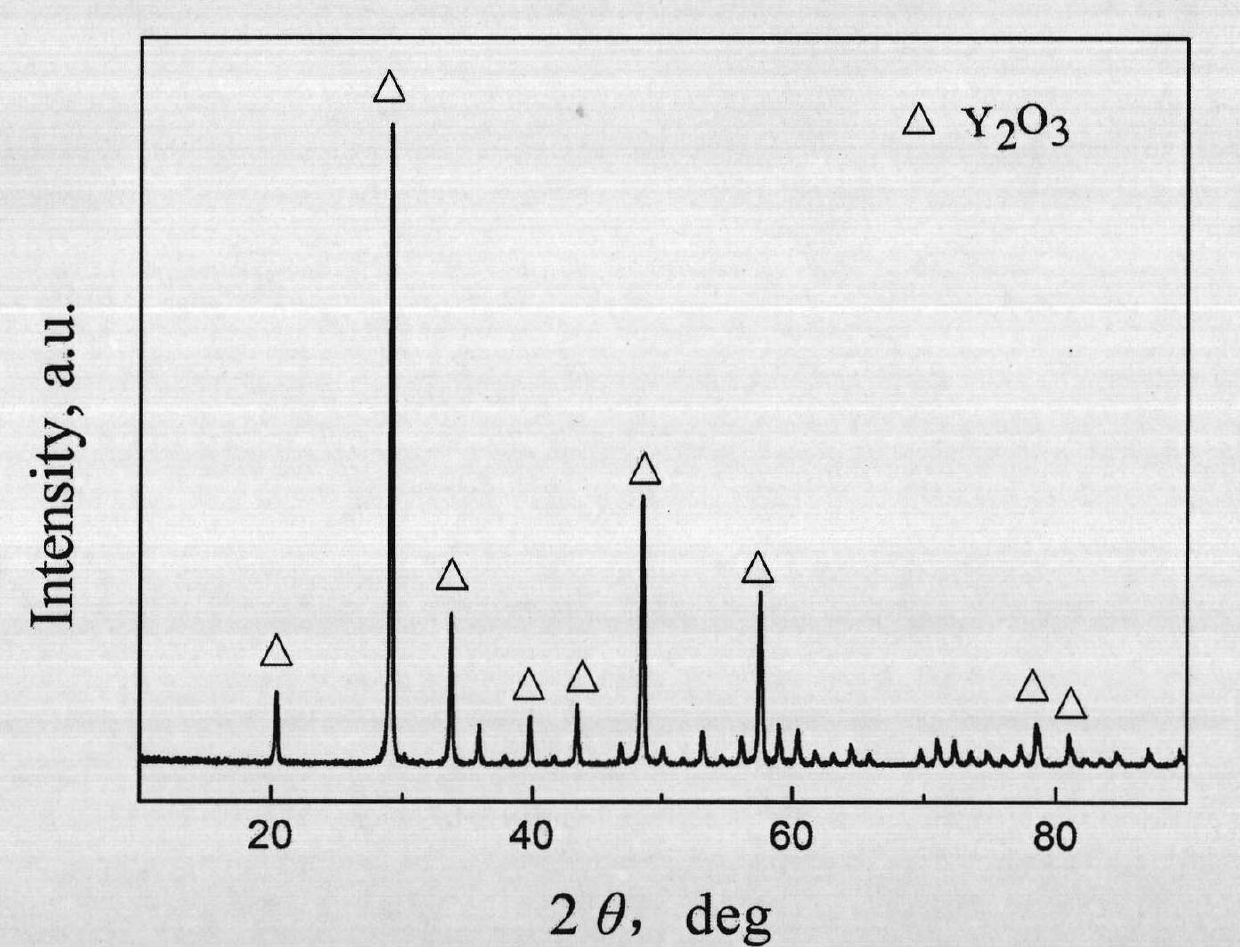

Examples

Embodiment 1

[0065] Step 1. Preparation of component A ceramic slurry

[0066] 500g of yttrium oxide with a particle size of 47 μm, 5g of polyvinyl alcohol and 100g of deionized water were stirred and mixed evenly to obtain component A ceramic slurry;

[0067] Step 2. Preparation of component B ceramic slurry

[0068] 330g of yttrium oxide with a particle size of 47 μm, 5g of polyvinyl alcohol and 100g of deionized water were stirred and mixed evenly to obtain component B ceramic slurry;

[0069] Step 3: Make foam template

[0070] Soak the polyurethane foam with a size of 45mm×45mm×20mm and a pore diameter of 10PPI in ammonia water with a pH value of 10 and a temperature of 45°C for 2 hours, then take it out, rinse it repeatedly with clean water, and wash off the ammonia water present in the polyurethane foam. After drying, a foam template is obtained;

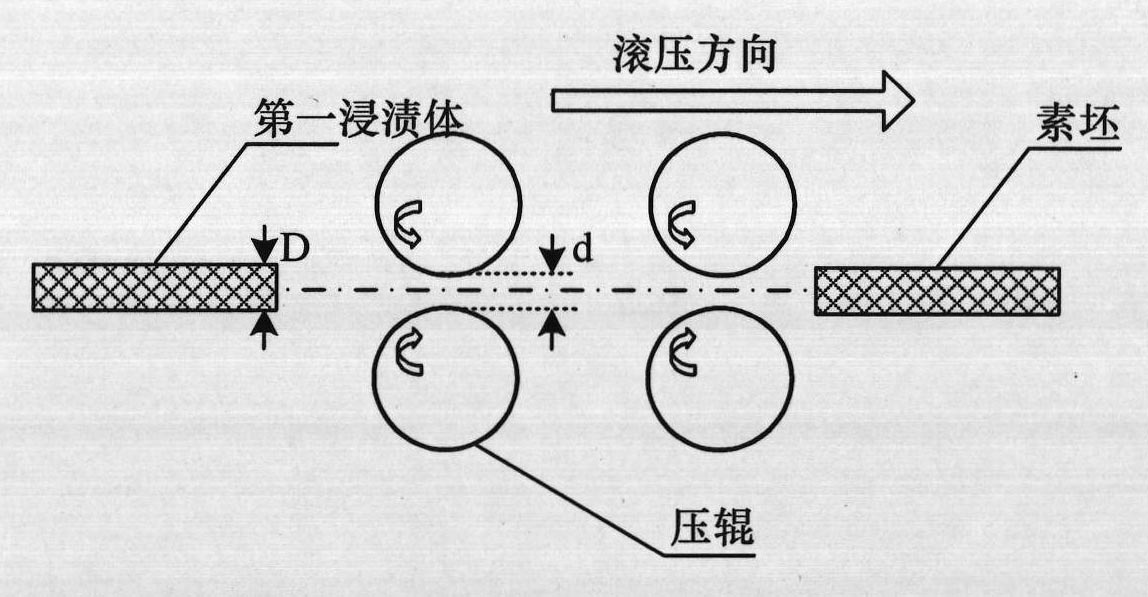

[0071] Step 4, pulping and drying

[0072] (A) Immerse the foam formwork prepared in step 3 into the component A ceramic slurry prep...

Embodiment 2

[0084] Step 1. Preparation of component A ceramic slurry

[0085] 348g of yttrium oxide with a particle size of 47μm, 116g of yttrium oxide with a particle size of 20μm, 116g of yttrium oxide with a particle size of 5μm, 3.6g of carboxymethyl cellulose, 36.4g of zirconia, 6.3g of ammonium polyacrylate and 100g of deionized After the water is stirred and mixed evenly, the A-component ceramic slurry is obtained;

[0086] Step 2. Preparation of component B ceramic slurry

[0087] 180g of yttrium oxide with a particle size of 30μm, 60g of yttrium oxide with a particle size of 20μm, 60g of yttrium oxide with a particle size of 5μm, 3.6g of carboxymethyl cellulose, 18.2g of zirconia, 3.6g of ammonium polyacrylate and 100g of deionized After the water is stirred and mixed evenly, the B component ceramic slurry is obtained;

[0088] Step 3: Make foam template

[0089] Soak the polyurethane foam with a size of Ф24mm×12mm and a pore diameter of 20PPI in a sodium hydroxide solution wi...

Embodiment 3

[0103] Step 1. Preparation of component A ceramic slurry

[0104] 380g of yttrium oxide with a particle size of 47μm, 190g of yttrium oxide with a particle size of 5μm, 5.6g of polyvinyl alcohol, 44.5g of aluminum oxide, 4.4g of polyammonium methacrylate and 100g of deionized water were mixed evenly to obtain component A Ceramic slurry;

[0105] Step 2. Preparation of component B ceramic slurry

[0106] 140g of yttrium oxide with a particle size of 47μm, 70g of yttrium oxide with a particle size of 5μm, 5.6g of polyvinyl alcohol, 11g of alumina, 2.2g of polyammonium methacrylate and 100g of deionized water were mixed evenly to obtain component B ceramics slurry;

[0107] Step 3: Make foam template

[0108] Soak the polyurethane foam with a size of 38mm×38mm×15mm and a pore diameter of 15PPI in a sodium hydroxide solution with a mass percentage concentration of 15% at a temperature of 50°C for 3 hours, take it out, rinse it repeatedly with clean water, and wash off the polyu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com