Optimizing system and method for shaft seal water of vacuum pump of ceramic filter

A ceramic filter and vacuum pump shaft technology, which is applied to chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of poor backwashing effect of ceramic filters, increased load of clean water pumps, and low water pressure of backwash water, etc. , to achieve the effect of reducing load, reducing maintenance rate and guaranteeing water quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

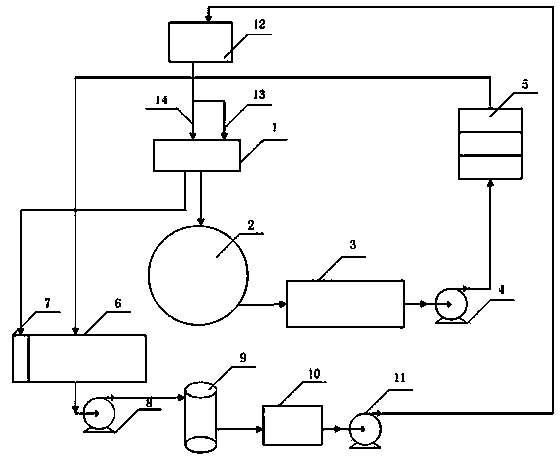

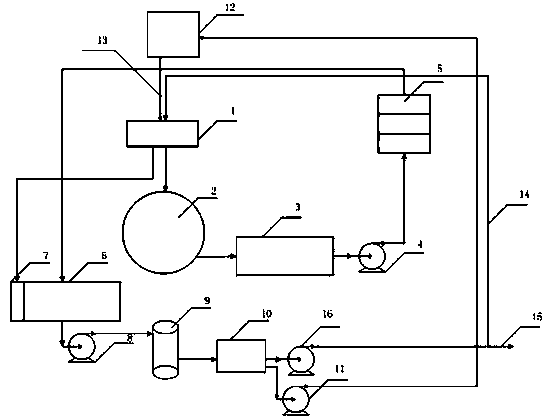

[0017] Combine below figure 2 , the present invention is further described:

[0018] Such as figure 2 As shown, the optimization system of ceramic filter vacuum pump shaft sealing water of the present invention comprises: ceramic filter 1, concentration tank 2, sewage tank 3, sewage pump 4, process sedimentation tank 5, collection tank 6, filtrate tank 7, collection pump 8 , Gravity filter 9, clean water pool 10, first clean water pump 11, high water tank 12, ceramic filter recoil water pipeline 13, vacuum pump shaft seal water pipeline 14, external network water pipeline 15 and second clean water pump 16.

[0019] The working principle is as follows: after the ceramic filter 1 starts demineralization, the filtrate water flows to the filtrate pool 7 by the natural height difference, and the overflow water in the tank of the ceramic filter 1 flows to the concentration pool 2, and the overflow water in the concentration pool 2 passes through After sedimentation, it flows to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com