Ceramic filtering system

A ceramic filtration and filter technology, which is used in semi-permeable membrane separation, permeation/dialysis water/sewage treatment, chemical instruments and methods, etc. , to achieve the effect of high fastness, good corrosion resistance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

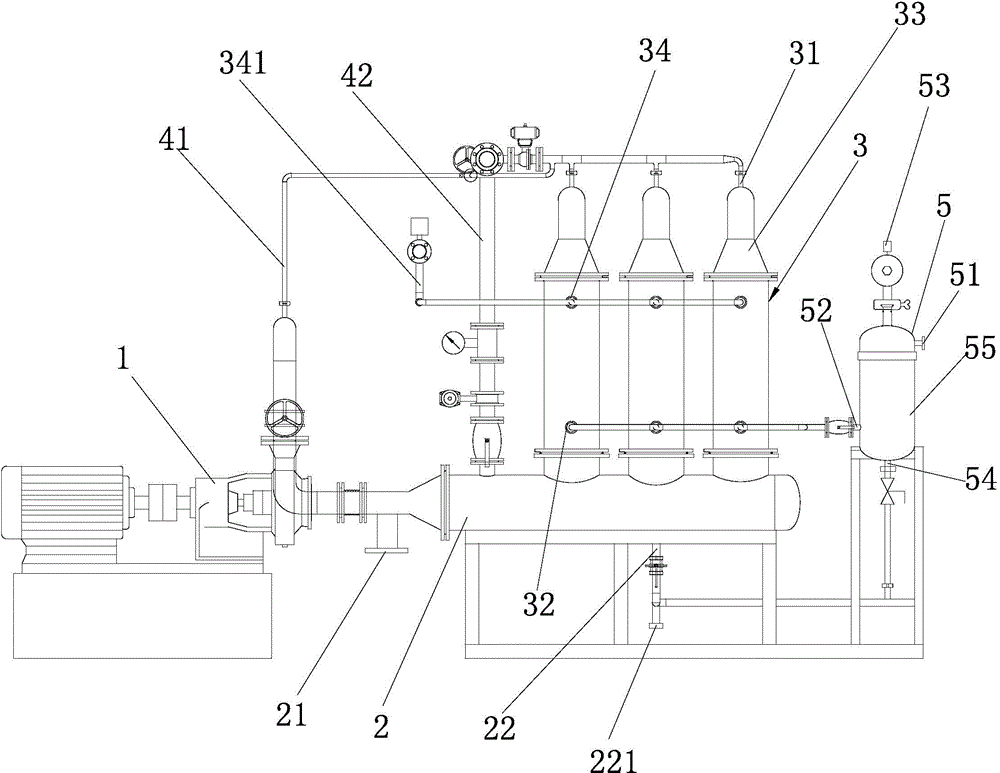

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] The invention discloses a ceramic filter system, which includes a circulation pump 1, a material delivery pipe 2 and a filter 3. Circulation pump 1 is connected with delivery pipe 2. The feeding pipe 2 is provided with a slurry inlet 21, and a feeding pump is connected to the feeding slurry inlet 21, and the feeding pump is connected with the raw material pool. The feeding pipe 2 and the filter 3 are arranged vertically, the feeding pipe 2 is arranged horizontally, and the filter 3 is arranged vertically. The side wall of the delivery pipe 2 communicates with the bottom end of the filter 3 . The top of the filter 3 is provided with an outlet 31 , and an adjustment pipeline is provided at the outlet 31 , and the adjustment pipeline includes a first pipeline 41 and a second pipeline 42 . In this embodiment, the slurry to be filtered is directly circulated in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com